Patterson-Kelley TBIG-03 User Manual

Page 12

Gemini™ Twin-Fuel Gas-Fired Boiler

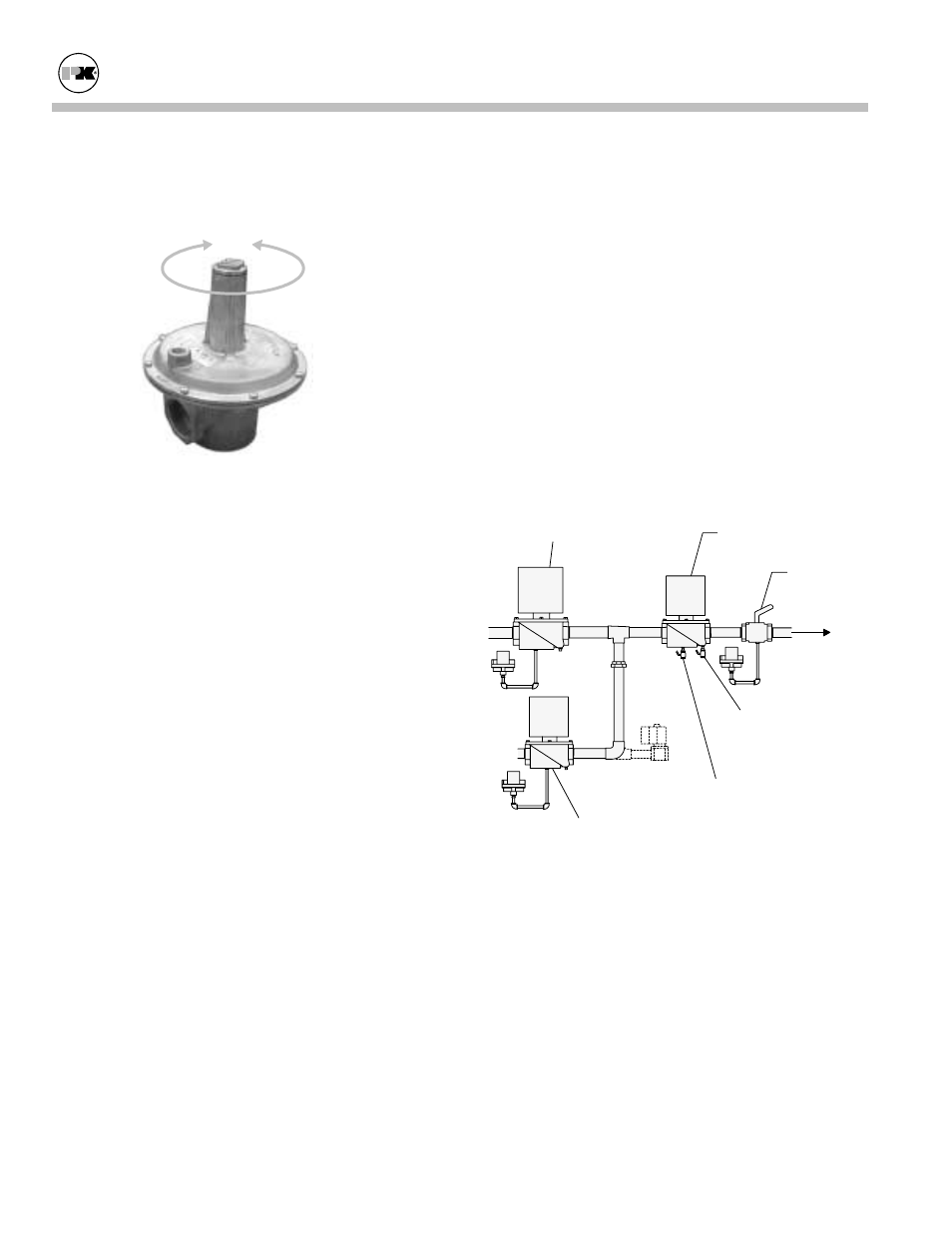

4.4.5 Gas Pressure Adjustment

Increase

Decrease

Figure 4-7 Regulator

The gas pressure is set initially during a factory fire-

test. A final adjustment must be made after the boiler

has been installed, as follows:

See rating plate for the minimum and maximum gas

pressure of the boiler.

Each boiler is furnished with three plugged taps in the

gas train for test gauge connections. Two taps are lo-

cated at the natural gas and propane manual shutoff

valves and are for measuring the gas supply pressure

(1/4" I.P.S.). The supply pressure during main burner

operation must be greater than the minimum indicated

on the rating plate (6 inches W.C. for natural gas, 6

inches W.C. for propane). The remaining tap is lo-

cated downstream from the secondary manual shutoff

valve at the elbow where the gas line enters the back

of the cabinet and is for measuring the manifold gas

pressure (1/8" I.P.S.).

If a replacement Lo-Hi-Lo actuator is required, follow

manufacturer's instructions and pre-set the "Lo" fire

setting of the actuator the same as the original actua-

tor. This must be performed by qualified service per-

sonnel.

To adjust gas pressure, first connect an appropriate

pressure-sensing device at the manifold tap, then re-

move seal cap from regulator. Turn adjusting screw

clock-wise to increase pressure, counter-clockwise to

decrease pressure. The manifold gas pressure on the

"Rating Plate," affixed to the back of the cabinet, is

provided only as a guide to the proper setting. The

manifold gas pressure indicated on the "Factory Fire-

test" label (affixed to the back of the cabinet) should

be used to achieve the proper firing rate of the

individual boiler as installed. Replace seal cap after

adjustment.

4

.4.6 Leak Testing of Valves

Annually test for by-pass leaks on all motorized gas

valves. If gas flows when the motorized gas valve is

closed it is defective.

downstream

leak test

valve

upstream

leak test

valve

motorized gas

valve (natural

gas)

motorized gas

valve (propane)

secondary

shutoff

to burner

secondary

motorized

gas valve

Figure 4-8 Leak Testing of Valves

Each branch of the gas train must be tested separately,

s follows:

a

1. Open the natural gas connection manual shutoff.

Close the propane connection manual shutoff.

(Refer to Figure 4-1.)

2. Close the secondary shutoff (downstream of all

motorized valves).

3. Attach a short piece of hose to the downstream

- 10 -