Guide specifications – Precisionaire Gas Turbine Rigid Filters Cell GT User Manual

Page 2

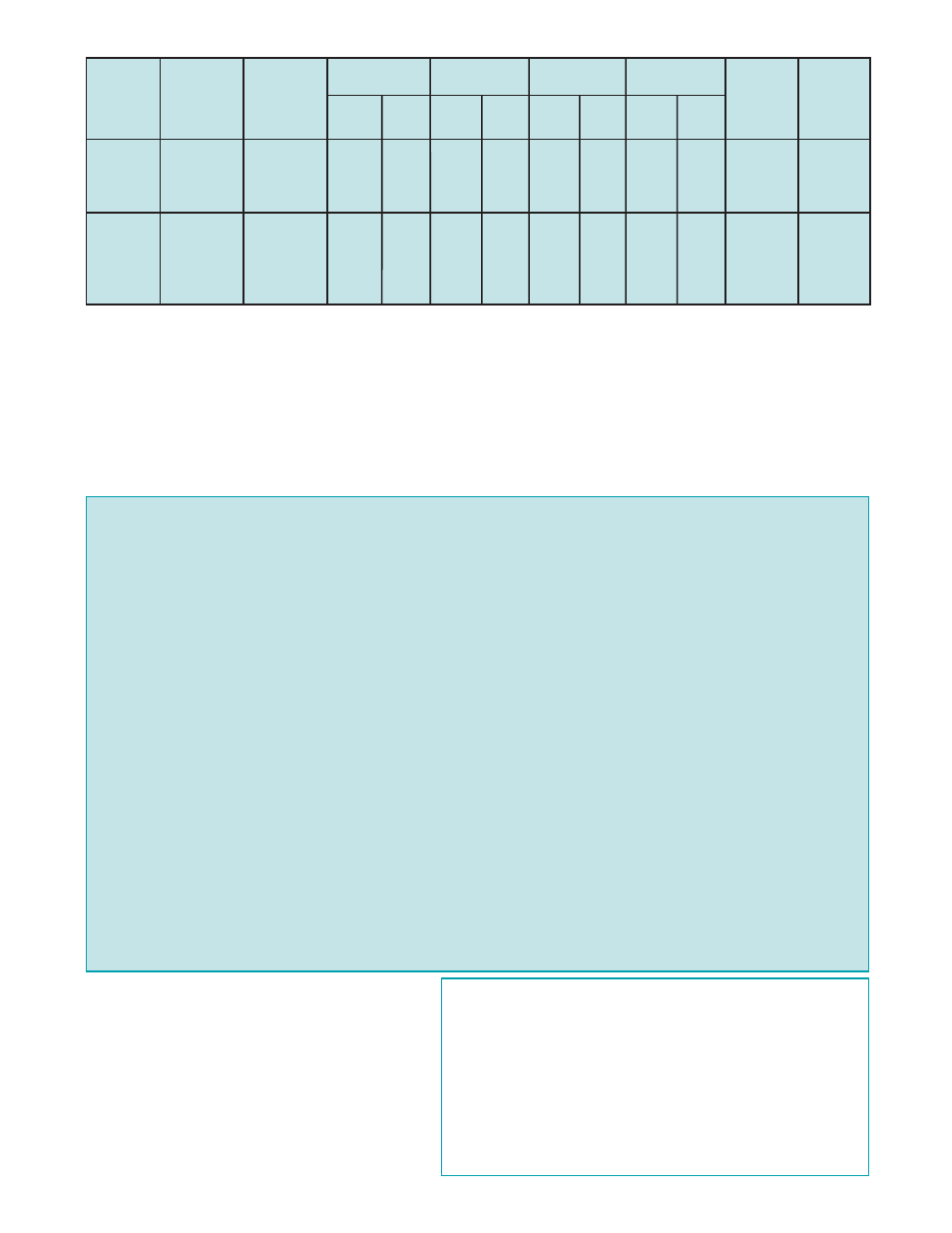

Nominal

Nominal

250 fpm

375 fpm

500 fpm

625 fpm

Media

Weight

Depth

Efficiency

Size

Area

Each

(inch)

HxWxD

cfm

pd

cfm

pd

cfm

pd

cfm

pd

(sq.ft.)

(lbs.)

(inch)

24x24x12

1000

1500

2000

2500

140

26

12

65%

.20

.35

.45

.57

24x12x12

500

750

1000

1250

69

14

24x24x12

1000

1500

2000

2500

140

27

12

95%

.25

.45

.65

.78

24x12x12

500

750

100

1250

69

14

Notes:

1. PD represents clean pressure drop in inchw.g. The recommended final pressure drop is 1.5 inch w.g.

2. Operation down to zero velocity is satisfactory for all models.

3. Performance tolerances conform to section 7.4 of ARI Standard 850.

4. Performance values stated may be averages typical of the products listed. Contact factory for actual performance

test reports on specific products.

5. Perfmormance values shown in this publication may be averages or estimates intended to generally represent

product styles. Always contact factory for latest actual test data on specific Flanders Precisionaire models.

1.0 General

1.1 Medium and high efficiency gas turbine rigid fil-

ters shall be PrecisionCell GT extended media

separator type filters as manufactured by

Flanders.

1.2 Filter sizes, efficiencies and capacities shall be

as scheduled on the drawings.

2.0 Filter Construction

2.1 Filters shall be constructed by pleating a con-

tinuous sheet of moisture-resistant dual layer,

wet-laid micro-fine glass media into closely

spaced pleats with hemmed-edge corrugated

aluminum separators.

2.2 The filter pack shall be compression sealed into

a 24 ga. corrosion-resistant steel frame.

2.3 The enclosing frame shall be assembled in a

rigid manner and shall incorporate a single or

double header as required by job conditions.

2.4 Corrosion-resistant steel expanded metal face-

guards shall be installed on the air entering and

leaving sides.

2.5 1/2” corrosion-resistant steel “T” straps shall be

installed on the air leaving side and horizontal

strap on air entering side.

2.6 Filters shall be UL 900 Class 1 listed.

3.0 Performance

3.1 Initial and final resistance shall not exceed the

scheduled values.

3.2 Media area must equal or exceed that of the

specified filter.

3.3 The average efficiency shall be as determined

by the ASHRAE Standard 52.1 and 52.2 test

methods.

3.4 The manufacturer shall guarantee performance

as stated in the literature within tolerances as

outlined in section 7.4 of ARI Standard 800.

Guide Specifications

REPRESENTED BY:

Flanders PrecisionAire

Foremost in Air Filtration

Toll Free: 1-800-637-2803