Constructing a featherboard – Porter-Cable (Model TS220LS) User Manual

Page 26

26

26

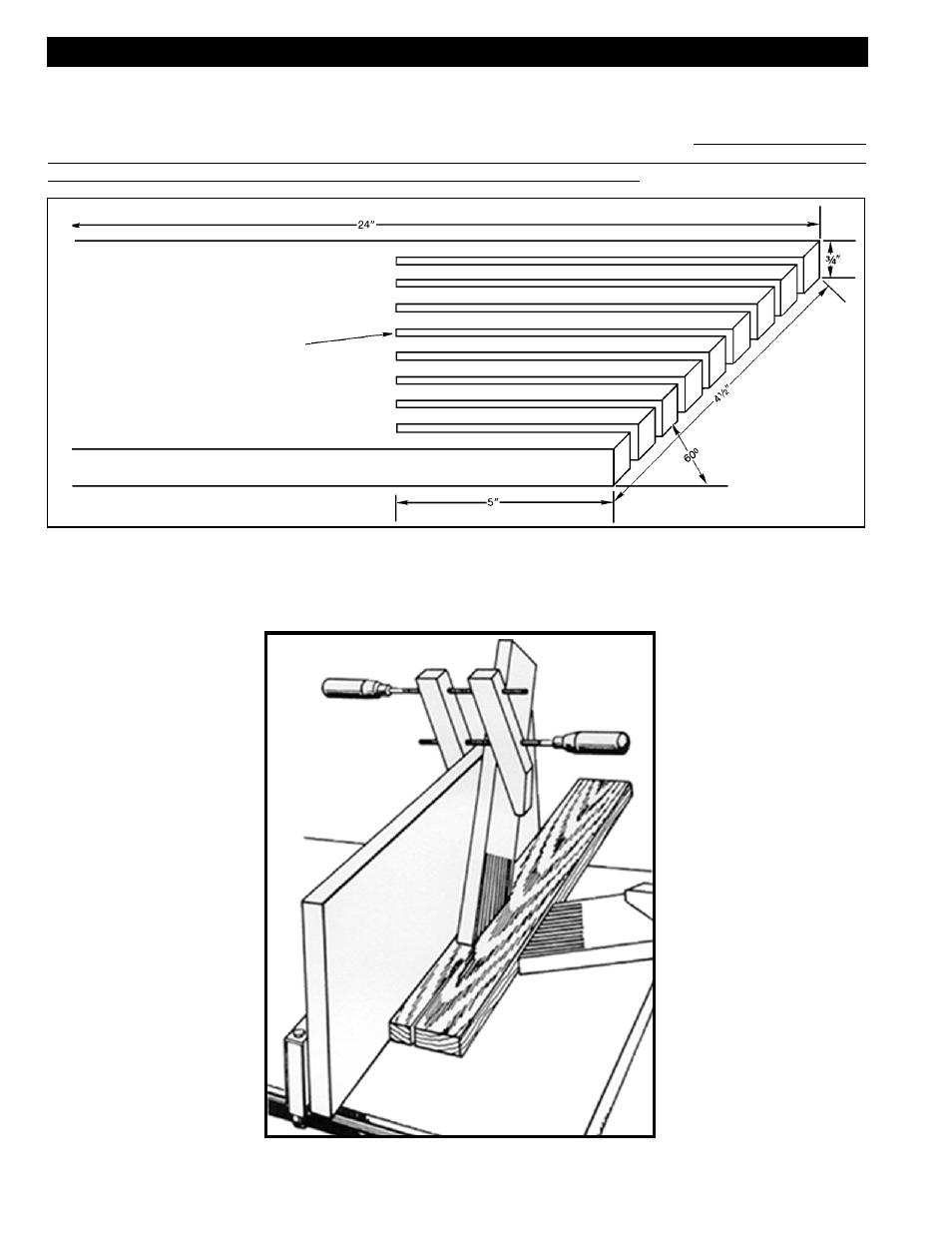

CONSTRUCTING A FEATHERBOARD

Fig. 59, illustrates dimensions for making a typical featherboard. The material which the featherboard is constructed

of, should be a straight piece of wood that is free of knots and cracks. Featherboards are used to keep the work in

contact with the fence and table and help prevent kickbacks. Clamp the featherboards to the fence and table so that

the leading edge of the featherboards will support the workpiece until the cut is completed. Use featherboards for all

non “thru-sawing” operations where the guard and spreader assembly must be removed (see Fig. 60). Always replace

the guard and spreader assembly when the non thru-sawing operation is completed.

Fig. 59

Fig. 60

Kerf should be

about 1/4" apart.

See also other documents in the category Porter-Cable Power saws:

- 36-729 (28 pages)

- 1500 (17 pages)

- PC600JS (32 pages)

- Dovetail Fixture/Jig 4113 (15 pages)

- 6605 (36 pages)

- 4210 (27 pages)

- METAL CUTTING SAW 440 (17 pages)

- PCB370SS (28 pages)

- 325MAG (15 pages)

- Double Insulated 10" Bench Top Table Saw 38129 (23 pages)

- 33-422 (28 pages)

- 90550124 (44 pages)

- 745 (52 pages)

- 447 (17 pages)

- 36-649 (32 pages)

- 347k (17 pages)

- 1400 (13 pages)

- FTS-150 (26 pages)

- XX55 (12 pages)

- 33-895X (32 pages)

- 3802L (23 pages)

- 345 (21 pages)

- 28-248 (28 pages)

- Miter Saw (4 pages)

- 4216 (44 pages)

- 36-225 (21 pages)

- 7549 (17 pages)

- Jig Saw (16 pages)

- 741 (16 pages)

- Model 543 (17 pages)

- Biesemeyer 1350734 (1 page)

- 725 (13 pages)

- PCB270TS (38 pages)

- 3802 (21 pages)

- 743 (17 pages)

- 3700L (23 pages)

- PC1800AG (72 pages)

- 28-306 (20 pages)

- 440 (48 pages)

- 3807 (19 pages)

- 4212 (44 pages)

- PTX3 (8 pages)

- 314 (7 pages)

- RS830 (30 pages)