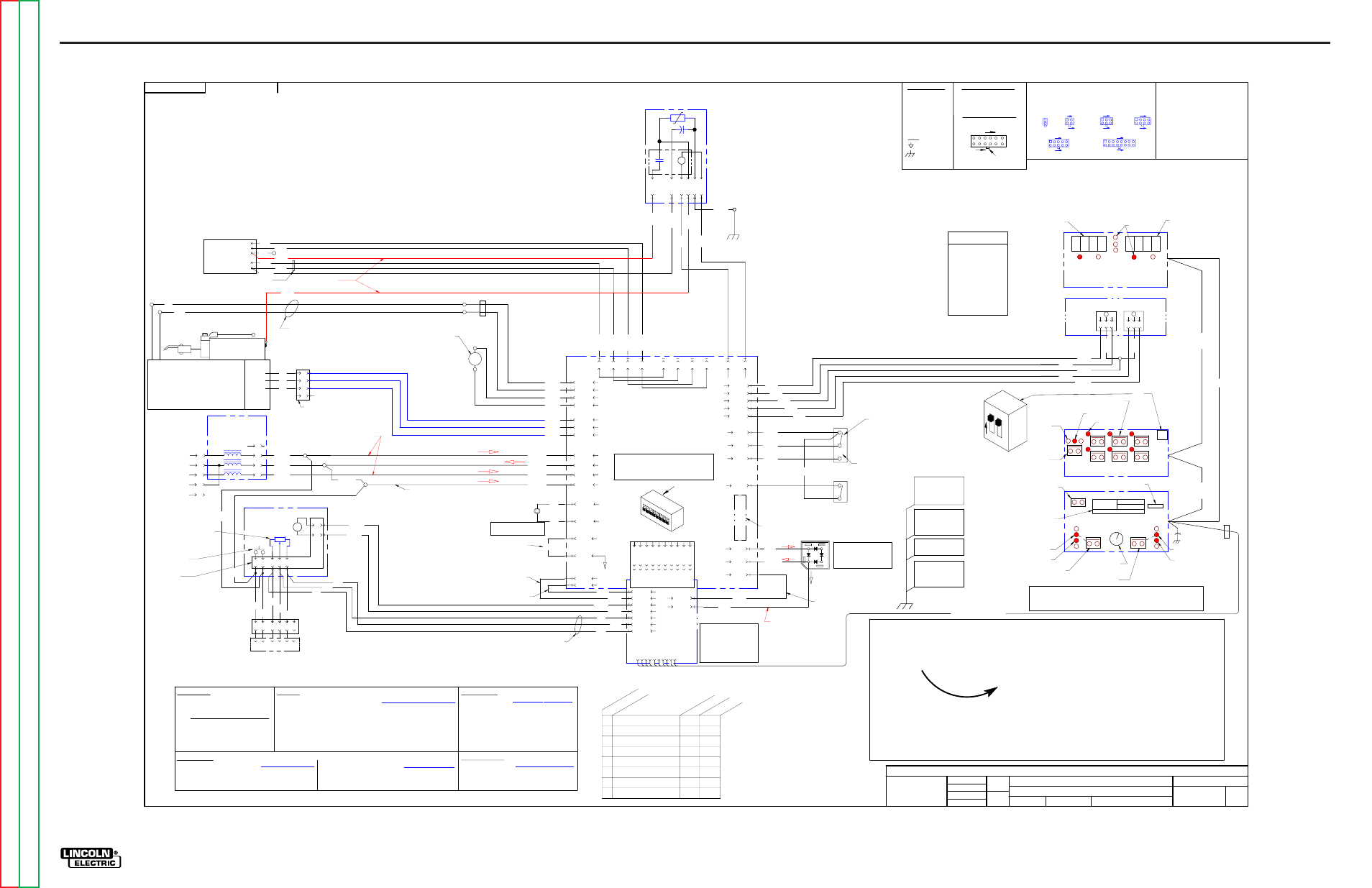

Electrical diagrams, Power feed 10m single/dual – Lincoln Electric POWER FEED 10M SINGLE/DUAL SVM172-A User Manual

Page 136

ELECTRICAL DIAGRAMS

G-6

POWER FEED 10M SINGLE/DUAL

SCHEMATIC - ENTIRE MACHINE - CODE 11086, 11216 (G4440)

E

THE INFORMATION ON THIS

PRINT IS FOR REFERENCE

ONLY. COMPONENTS AND

CIRCUITRY MAY BE

DIFFERENT

FROM AN ACTUAL MACHINE.

G4440

POWER FEED 10M SINGLE (BENCH)

MACHINE SCHEMATIC

NONE

-

TJP

ZUCKER

DRAWN BY:

DESIGN INFORMATION

ENGINEER:

APPROVED:

REFERENCE:

EQUIPMENT TYPE:

SUBJECT:

SCALE:

MATERIAL

DISPOSITION:

APPROVAL

DATE:

PROJECT

NUMBER:

UF

CRM22115-FX

1

PAGE ___ OF ___

1

DOCUMENT

NUMBER:

DOCUMENT

REVISION:

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED

TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

PROPRIETARY & CONFIDENTIAL:

6/19/2006

J86

CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF P.C. BOARD)

J81,J82

6

5

10

1

3

4

1

2

J85,J87

9

8

16

1

4

6

1

3

J84,J810

5

4

8

1

J1,J83,J88

GENERAL INFORMATION

ELECTRICAL SYMBOLS PER E1537

COLOR CODE

B -

BLACK

W -

WHITE

R -

RED

U -

BLUE

J2,J811

1

2

B-BLACK

R-RED

U-BLUE

W-WHITE

COMPONENT VALUE UNITS:

CAPACITOR: MFD/VOLTS

RESISTOR: OHMS/WATTS

CONNECTOR PIN NUMBERS:

VIEW OF CONNECTOR ON PC BOARD

1

6

7

12

LATCH

EX. 12 PIN CONNECTOR

LABELS:

COMMON

FRAME GROUND

P10

FEED HEAD

P.C. BOARD

4J88

3

2

1

CURRENT

WFS

VOLTS

TRIM

PANEL ENCODERS

2 STEP/ 4 STEP

SWITCH

-

+

DIODE BRIDGE

5-32 VDC

1.8 OHMS

13 SECOND AVERAGE CURRENT

LIMIT = 6.3A

(LIMIT IS SOFTWARE SET)

50-800/PM OR 75-1200PM

1

+15V

2

+5V

3

/SS

4

CS1

5

CS2

6

CS3

7

MISO

8

SCK

9

MOSI

10

COM

FOR ALL FLEX AND

SHIELDED CABLE

PUSH-PULL GUN

DAUGHTER

P.C. BOARD

5K

7 PIN

PUSH-PULL

GUN

CONNECTION

PROVIDES BRAKING

OF THE PUSH-PULL

GUN MOTOR AND

CONDITIONS THE

SIGNAL FROM THE

POTENTIOMETER.

2J811

TO PUSH-PULL

GUN MOTOR DRIVE

+40V DC SUPPLY FOR

PUSH-PULL GUN MOTOR

(NON-ISOLATED)

DISPLAY P. C. BOARD

(SCHEMATIC:L11756)

OPTIONAL MEMORY P.C. BOARD

(SCHEMATIC:L11897)

FLEX

(OPTIONAL)

E

L1

TOROID

3J81

4J81

5 PIN ARCLINK

CONNECTOR TO

POWER SOURCE

{

TRIGGER

0V TO COMMON WHEN

SWITCH CLOSED

+15VDC

9J85

6J85

5J84

579A

COLD INCH/

GAS PURGE SWITCH

COLD INCH

GAS PURGE

579

586

535

ARC VOLTAGE

FEEDBACK

GAS

PERFORMS ALL USER INTERFACE,

WIRE DRIVE, AND GAS SOLENOID

CONTROL FUNCTIONS.

S9

MSP4 P.C. BOARD

(SCHEMATIC: G4456)

LEDS

LED DISPLAY

LED DISPLAY

A-GUN-B

PUSHBUTTON

LED

1

2

O

N

SINGLE

HEAD

DUAL

HEAD

FEEDER

FUTURE

S9

SEE IM MANUAL FOR ERROR CODES

OR WWW.POWERWAVESOFTWARE.COM

OR SERVICE NAVIGATOR DIAGNOSTIC UTILITIES

MEMORY

PANEL

MSP4

PANEL

DISPLAY

PANEL

SET SWITCH 1 "ON"

(SINGLE HEAD) AND

SWITCH 2 "ON" (FEEDER) AS

SHOWN ON DIP SWITCH S9.

MOTORS WILL NOT

RUN IF DIODE IS

OPEN, REVERSED,

OR DISCONNECTED

M

O

T

O

R

+

CAPACITOR

CAPACITOR CONNECTS

FROM PIN 10 OF SHIELDED

CABLE TO FRAME GROUND.

6J

1

SELECT P.C. BOARD

2J

2

513

400F

1J

1

2J

1

3J

1

4J

1

J2

CASE

67A

51

4

2J81 1J81

4J82 3J82 2J82 1J82 14J85 13J85

+15V

O

V

W

HE

N

"O

N

"

NOTE: WILL WORK WITH

LINKNET POWER SOURCE BUT

WILL ONLY SHOW AND HAVE

LINKNET FEATURES

A

B

D

E

541

542

67B

540

500

500B

INPUT ELECTRODE

CABLE CONNECTION

67A

FEED PLATE

GENERAL

GMAW

STD. CV

5

CV GMAW POWER MODE

40

FCAW

STD. CV

6

STICK SOFT (7018)

1

STICK CRISP (6010)

2

CC TIG

TOUCH START

3

GOUGE

---

9

ALUMINUM

0.035

3/64

1/16

GMAW

Ar 148

71

73

4043 PULSE

Ar 149

72

74

PULSE ON PULSE Ar 98

99

100

50

0B

(SCHEMATIC S24779)

+15VDC

+5VDC

SIGNAL

STEEL

0.030 0.035 0.045 0.052

GMAW

CO2

---

10

20

24

GMAW

Ar (MIX)

94

11

21

25

PULSE (CRISP)

Ar (MIX)

95

12

22

26

PULSE (SOFT)

Ar (MIX)

---

14

19

28

STT (NO TAIL OUT) CO2 Ar/CO2

109

109

125

125

STTll

CO2 Ar/CO2

110

110

126

126

0.035 3/64 1/16

GMAW

Ar

151

75

77

5356 PULSE

Ar

152

76

78

PULSE ON PULSE Ar

101

102

103

STAINLESS

0.030

0.035

0.045

GMAW Ar (MIX)

61

31

41

GMAW Ar/He/CO2 63

33

43

PULSE Ar/CO2

66

36

46

PULSE Ar/O2

62

32

42

PULSE Ar/He/CO2 ---

34

44

STT

Ar/He/CO2 109

109

125

STTll

Ar/He/CO2 110

110

126

METAL CORE

0.045

0.052

1/16

GMAW Ar/CO2

81

83

85

PULSE Ar/CO2

82

84

86

WFS

AMPS

VOLTS

TRIM

3

2

1

580

58

5B

58

5A

587

585

582

581

FLEX

(OPTIONAL)

FLEX

-OR-

SET UP LED

WELD MODE, WIRE SIZE,

ERROR CODES, SEVEN

SEGMENTAND ALPHA

NUMERIC DISPLAY

INFRARED TRANSCEIVER

(WIRELESS COMMUNICATION)

WELD MODE LED

ARC CONTROL LED

SELECT PUSHBUTTON

SELECT PUSHBUTTON

END OPTIONS LED

START OPTIONS LED

16 DETENT

ENCODER

67B

54

1

54

2

50

0

54

0

CA

N

CA

N

COM

+40VD

C

8

7

6

5

4

3

2

1

SHIELDED CABLE

6J810

4J810

3J810

2J810

8J810

1J810

5J810

526

548

6J84

6J85

8J84

1J88

518

PUSH-PULL GUN

BRAKE SIGNAL

(0 VOLT = MOTOR BRAKE

0-5V PUSH-PULL GUN

POTENTIOMETER SIGNAL

REQUIRED FOR

4 STEP MODE

16J85

15J85

B

W

RED/GREEN

STATUS LED

SEE ERROR TABLE

IN IM MANUAL

HIGH

ON

DE

F.

LOW

OF

F D

EF

.

FEED SPEED GEAR

8

FU

NC

TION

7

6

5

4

3

2

DIP SWITCH S1 SETTING CHART

TO

GG

LE

NO

.

1

POLARITY

NEG

SPARE

POS

10

J8

6

9J

86

8J

86

7J

86

6J

86

5J

86

4J

86

3J

86

2J

86

1J

86

10P

86

9P

8

6

8P

8

6

7P

8

6

6P

8

6

5P

8

6

4P

8

6

3P

8

6

2P

8

6

1P

8

6

(SCHEMATIC L12008)

ON

OFF

S

1

S

EE S1

SETTING

C

HART

(SCHEMATIC G3883)

1J811

5J83

5J83

554

640A

5J88

595

640

SET UP MENU

To access, press the right and left push buttons

on the MSP4 panel simultaneously

Setup feature numbers may vary between software

versions. Must read small display to find your

specific feature you want. These P numbers listed

are for reference.

SET UP MENU FEATURES

P.0 = On/Off enter exit set up mode

P1 = WFS English/metric

P2 = Left display amps/wfs

P4 = Trigger memory recall

P5 = Trigger procedure change

P6 = Stall factor

P7 = Push pull gun offset

P8 = New TIG solenoid feature

P80-89 = Senses from studs on S25629-09

P99 = Show test mode 200.201

P100 = View diagnostics

P102 = Fatal log

P103 = View software

P104 = Hardware version

P105 = Welding software

P200 = CC test 25-600

P201 = CV test 10-35

P202 = CC test 10A

P203 = CC test 355A

P204 = CC test 455A

P205 = CC test 550A

P206 = CV test 10V to 30 V

P207 = 1/0 test 25-600

P208 = STT test 170A

P209 = 1 curve 0-600A

P210 = Step resp background

P211 = V curve 0-70V 10-70V

P212 = OCV test

P215 = Touch sense

P255 = Show weld file

10J85

7J85

5J85

12J85

11J85

580

587

585

582

581

S4

S2

1J83

2J83

3J83

4J83

DUAL

PROCEDURE

A

C

SCHEMATIC M19487

PROCEDURE

A = OPEN

B = CLOSED

1J84

7J84

4J84

2J85

1J85

3J85

4J85

532B

570C

543

MOTOR GEARBOX

TACH

1

2

3

4

R

U

B

R

U

B

5VDC TACH SUPPLY

TACH SIGNAL

TACH COM

B

W

ACCESS THIS

CONNECTOR BY REMOVING

THE WIRE DRIVE

ASSEMBLY ACCESS DOOR

550

551

553

554

PWM CONTROLLED

6.5 VDC WHEN GAS IS

FLOWING. COIL

MEASURES 21 OHMS.

12 VDC COIL

L2

TOROID

MOTOR +

MOTOR -

GAS SOLENOID +

GAS SOLENOID -

531

537

534

TRIGGER

SUPPLY FOR TRIGGER AND DUAL

DUAL PROCEDURE

0VDC @ 50 IN/MIN

24VDC @ 700 IN/MIN

OPTIONAL 6 PIN

REMOTE FOOT

AMPTROL CONNECTION

(WIRE DRIVE BOX REAR)

570E

532E

77E

76E

75E

4 5 6 3 2 1

D A C B F

B

A

M

E F C D G

75

76

77

M

O

T

O

R

-

570A

570

532A

570B

P13

P14

3218

3214

3218

3214

76

75

77

(WIRE DRIVE REAR LOW)

(WIRE DRIVE REAR)

P11

(WIRE DRIVE FRONT)

PUSH-PULL GUN WIRE

FEED SPEED CONTROL

PUSH-PULL

GUN TRIGGER

AMPHENOL

(LOWER REAR )

SHUTDOWN INPUT (DISCONNECT

FOR FLOW SWITCH CONNECTION)

(INSIDE WRAPAROUND)

+40

AC

(WIRE DRIVE FRONT)

(WIRE DRIVE FRONT)

PCT AND RESISTORS

PROTECTED ON

DAUGHTER BOARD

J87 NOT USED

CLEAN ROOM USE

P15

P16

L3

4

2

1

REAR ACCESS

PANEL

(DRIVE MOTOR

PANEL DIVIDER)

(FRONT BASE)

CONTROL BOX

FRONT AND

REAR

(DIVIDER PANEL REAR

ACCESS DOOR SIDE)

532

570D

543

D

E

B

{

3

P9

SPARE

SPARE

SPARE

SPARE

SPARE

(DIVIDER PANEL)

FILTER P.C. BD.

SPOOL GUN/PUSH-PULL MOTOR

C

67

LED

A-GUN-B

MEMORY IS STORED ON

U/I FEED BOARD

Grid load testing use

}

WELD MODE SELECTIONS (POWER SOURCE WELD FILE DEPENDENT

AVG. = 2V

50/IPM = 125 HZ.

400/IPM = 985 HZ.

800/IPM = 1.970K HZ.

}

TYPICAL CURRENT:

DRAW @ 600/PM = 1.6 AMPS

@ 800/PM = 1.85 AMPS

G-6

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.