Troubleshooting – Lochinvar KNIGHT 81-286 User Manual

Page 40

3

Troubleshooting

Service Manual

40

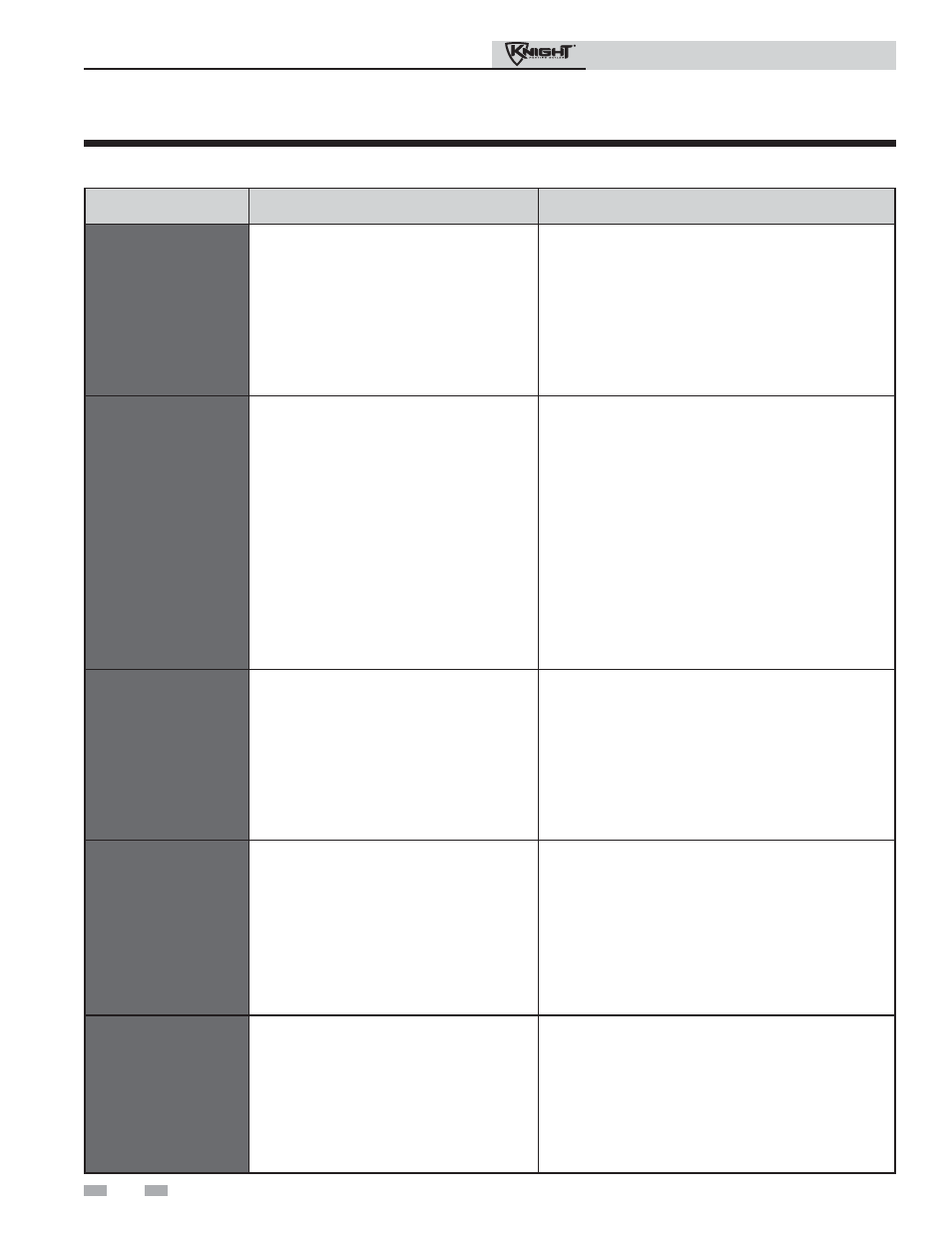

Table 3-4 (continued from previous page) Troubleshooting Chart - Fault Messages Displayed on Boiler Interface

FAULT

DESCRIPTION

CORRECTIVE ACTION

GV/Relay

Fail

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

SMART SYSTEM display

to reset.)

The main control board did not detect the

gas valve.

• Check wiring harness connection at the gas valve and

at the main control board.

• Replace the gas valve wire harness.

• Replace the gas valve.

• Replace the main control board.

Fan High

OR

Fan Speed High

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

SMART SYSTEM display

to reset.)

The actual fan RPM is 30% higher than what

is being called for.

• Vent/air intake lengths exceed the maximum allowed

lengths. Refer to Section 3 - General Venting of the

Knight Boiler Installation and Operation Manual for

proper lengths.

• Check for obstruction or blockage in the vent/air

intake pipes or at terminations.

• Check the wiring connections at the fan and at the

main control board.

• Replace the fan.

• Replace the main control board.

Sensor Open

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

SMART SYSTEM display

to reset.)

Either the inlet water or outlet water

temperature sensor has been disconnected.

• Check the sensors and their associated wiring.

Repair or replace the sensor or wiring if damaged.

• Measure the resistance of the sensors and compare

the resistance to the tables on page 35 of this

manual.

• Replace the sensor if necessary.

Sensor Shorted

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

SMART SYSTEM display

to reset.)

Either the inlet water or outlet water

temperature sensor has been shorted.

• Check the sensors and their associated wiring.

Repair or replace the sensor or wiring if damaged.

• Measure the resistance of the sensors and compare

the resistance to the tables on page 30 of this

manual.

• Replace the sensor if necessary.

Louver Proving

Sw

(will require a manual

reset once the condition

has been corrected. Press

the RESET button on the

SMART SYSTEM display

to reset.)

An optional remote proving switch is not

making.

• Check function of remote devices.

• Check for loose or misplaced jumper if auxiliary

proving switch is not installed.