LG 395CAV User Manual

Page 8

The furnace must have a 115-v power supply properly connected

and grounded. Proper polarity must be maintained for correct

operation. Thermostat wire connections at R, W, C, and Y must be

made at the 24-v terminal block on the control board. The gas

service pressure must not exceed 0.5 psig (14-in. wc), but must be

no less than 0.16 psig (4.5-in. wc).

CAUTION:

This furnace is equipped with a manual

reset limit switch or fuse link in the gas control area. The

switch or fuse link opens and shuts off power to the gas

valve if a flame rollout or overheating condition occurs in

the gas control area. DO NOT bypass the switch. Correct

inadequate combustion air supply problem and reset the

switch or replace the fuse link.

Before operating the furnace, check each manual reset switch for

continuity. If necessary, press the button to reset the switch.

The blower compartment door must be in place to complete the

115-v circuit to the furnace.

B.

Sequence of Operation

CAUTION:

Furnace control must be grounded for

proper operation, or control will lockout. Control is

grounded through green wire routed to gas valve and

burner bracket screw.

Using the schematic diagram shown in Fig. 11, follow the

sequence of operation through the different modes. Read and

follow the wiring diagram very carefully.

NOTE:

If there is a power interruption and any thermostat call,

the control initiates a 90-sec blower only on period before starting

another cycle.

TABLE 5—ELECTRICAL DATA

UNIT SIZE

VOLTS—

HERTZ—

PHASE

OPERATING

VOLTAGE RANGE

MAXIMUM

UNIT AMPS

MINIMUM

WIRE GAGE

MAXIMUM

WIRE LENGTH (FT)‡

MAXIMUM

FUSE OR

HACR-TYPE CKT

BKR AMPS†

Maximum*

Minimum*

024045

115—60—1

127

104

6.0

14

47

15

036045

115—60—1

127

104

8.3

14

34

15

024070

115—60—1

127

104

5.9

14

47

15

036070

115—60—1

127

104

8.7

14

32

15

042091

115—60—1

127

104

9.0

14

31

15

048091

115—60—1

127

104

10.4

14

27

15

036110

115—60—1

127

104

8.0

14

35

15

048111

115—60—1

127

104

10.1

14

28

15

060111

115—60—1

127

104

14.4

12

31

20

048135

115—60—1

127

104

10.1

14

28

15

060135

115—60—1

127

104

13.3

12

33

20

060155

115—60—1

127

104

14.0

12

31

20

* Permissible limits of the voltage range at which the unit operates satisfactorily.

† Time-delay fuse is recommended.

‡ Length shown is as measured 1 way along wire path between unit and service panel for maximum 2 percent voltage drop.

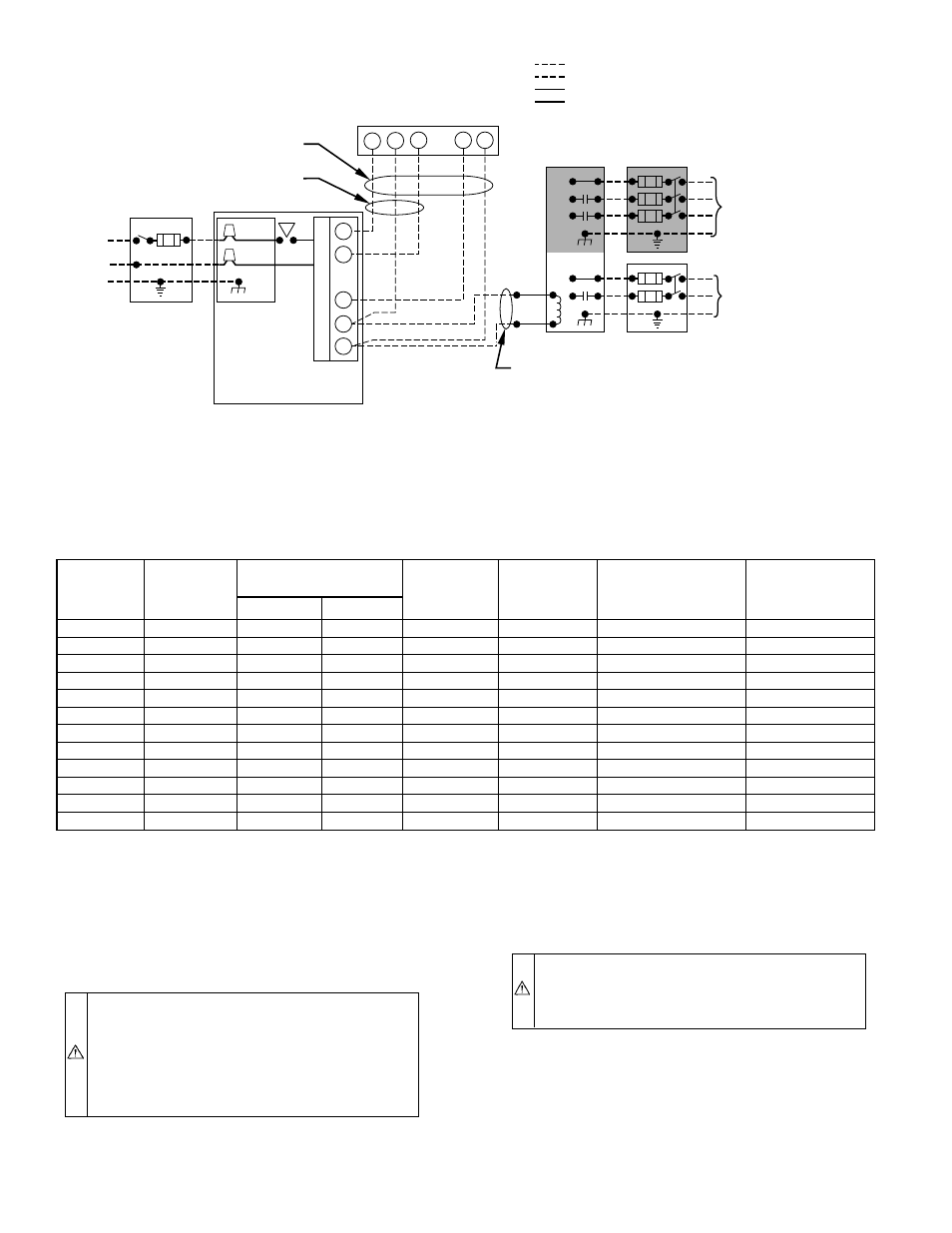

Fig. 8—Heating and Cooling Application Wiring Diagram

A95241

115-VOLT FIELD-

SUPPLIED

FUSED

DISCONNECT

AUXILIARY

J-BOX

CONTROL

BOX

24-VOLT

TERMINAL

BLOCK

THREE-WIRE

HEATING-

ONLY

FIVE

WIRE

NOTE 1

NOTE 2

FIELD-SUPPLIED

FUSED DISCONNECT

CONDENSING

UNIT

TWO

WIRE

FURNACE

R

G

C

W

C

R

G

Y

GND

GND

FIELD 24-VOLT WIRING

FIELD 115-, 208/230-, 460-VOLT WIRING

FACTORY 24-VOLT WIRING

FACTORY 115-VOLT WIRING

208/230- OR

460-VOLT

THREE

PHASE

208/230-

VOLT

SINGLE

PHASE

WHT

BLK

WHT

BLK

NOTES:

Connect Y-terminal as shown for proper operation.

Some thermostats require a "C" terminal connection as shown.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

W

Y

GND

THERMOSTAT

TERMINALS

1.

2.

3.

—8—