LG 395CAV User Manual

Page 12

b. Check gas input rate by clocking gas meter.

(1.) Obtain average yearly heat value for local gas

supply.

(2.) Check and verify orifice size in furnace. NEVER

ASSUME

THE

ORIFICE

SIZE.

ALWAYS

CHECK AND VERIFY.

CAUTION:

DO NOT redrill burner orifices. Improper

drilling (burrs, out of round, etc.) can cause excessive

burner operating noise and misdirection of burner flames.

This could result in flame impingement on burners and

heat exchanger surfaces, leading to potential failures.

(3.) Turn off all other gas appliances and pilots.

(4.) Start furnace and let run for 3 minutes.

(5.) Measure time (in sec) for gas meter to complete 1

revolution.

(6.) Refer to Table 7 for cu ft of gas per hr.

(7.) Multiply gas rate (cu ft/hr) by heating value (Btu/cu

ft).

EXAMPLE:

Btu heating input = Btu/cu ft X cu ft/hr

Heating value of gas = 1070 Btu/cu ft

Time for 1 revolution of 2 cu ft dial = 72 sec

Gas rate = 100 X 1070 = 107,000 Btuh

(8.) Measured gas input should not exceed gas input on

unit rating plate.

(9.) Proceed to item c to adjust manifold pressure.

c. Adjust gas input.

(1.) Remove regulator adjustment seal cap. (See Fig.

12.)

(2.) Turn adjusting screw counterclockwise to decrease

input. Turn screw clockwise to increase input. DO

NOT set manifold pressure less than 3.2-in. wc or

more than 3.8-in. wc for natural gas. Make any

major adjustments by changing main burner ori-

fices.

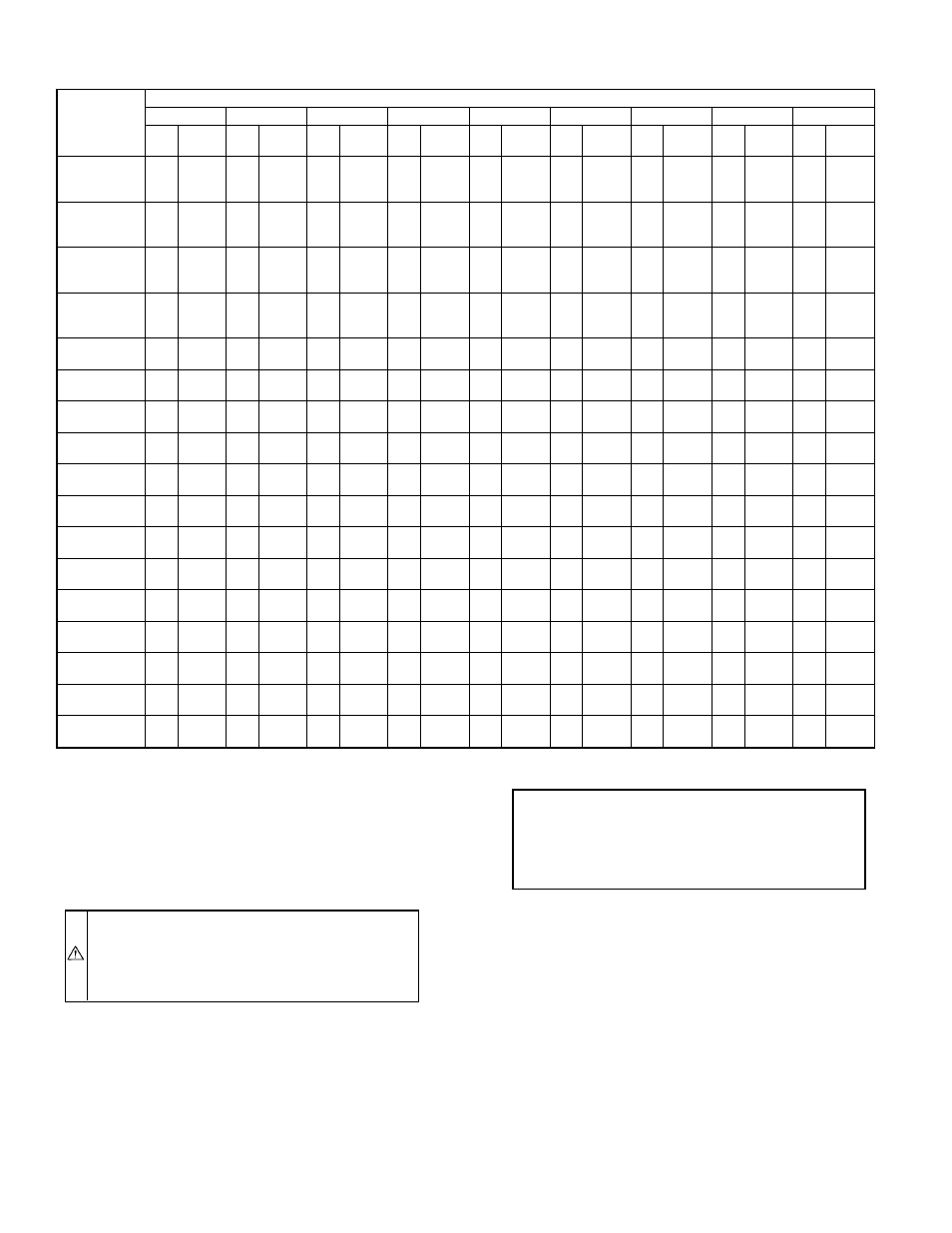

TABLE 6—MODEL 395CAV ORIFICE SIZE AND MANIFOLD PRESSURE FOR CORRECT INPUT RATE

(Tabulated Data Based on Altitude Up to 2000 Ft and 22,000 Btuh Per Burner)

GAS

HEAT

VALUE

(BTU/CU FT)

SPECIFIC GRAVITY OF NATURAL GAS

0.56

0.58

0.60

0.62

0.64

0.66

0.68

0.70

0.72

Orf

No.

Mnfld

Press.

Orf

No.

Mnfld

Press.

Orf

No.

Mnfld

Press.

Orf

No.

Mnfld

Press.

Orf

No.

Mnfld

Press.

Orf

No.

Mnfld

Press.

Orf

No.

Mnfld

Press.

Orf

No.

Mnfld

Press.

Orf

No.

Mnfld

Press.

860

41

42

—

3.2

3.6

—

41

42

—

3.3

3.7

—

41

42

40

3.4

3.8

3.2

41

40

—

3.5

3.3

—

41

39

40

3.7

3.2

3.4

41

39

40

3.8

3.3

3.5

39

40

—

3.4

3.6

—

38

39

40

3.2

3.5

3.7

38

39

40

3.3

3.6

3.8

875

42

—

—

3.4

—

—

41

42

—

3.2

3.6

—

41

42

—

3.3

3.7

—

41

42

40

3.4

3.8

3.2

41

40

—

3.5

3.3

—

41

39

40

3.6

3.2

3.4

41

39

40

3.8

3.3

3.5

39

40

—

3.3

3.6

—

38

39

40

3.2

3.4

3.7

890

42

—

—

3.3

—

—

42

—

—

3.4

—

—

41

42

—

3.2

3.6

—

41

42

—

3.3

3.7

—

41

42

—

3.4

3.8

—

41

40

—

3.5

3.2

—

41

40

—

3.6

3.3

—

41

39

40

3.7

3.2

3.4

41

39

40

3.8

3.3

3.5

905

42

—

—

3.2

—

—

42

—

—

3.3

—

—

42

—

—

3.4

—

—

41

42

—

3.2

3.6

—

41

42

—

3.3

3.7

—

41

42

—

3.4

3.8

—

41

40

—

3.5

3.2

—

41

40

—

3.6

3.3

—

41

39

40

3.7

3.2

3.4

920

43

—

3.8

—

42

—

3.2

—

42

—

3.3

—

42

—

3.4

—

41

42

3.2

3.5

41

42

3.3

3.7

41

42

3.4

3.8

41

40

3.5

3.2

41

40

3.6

3.3

935

43

—

3.7

—

43

—

3.8

—

42

—

3.2

—

42

—

3.3

—

42

—

3.4

—

41

42

3.2

3.5

41

42

3.3

3.7

41

42

3.4

3.8

41

40

3.5

3.2

950

43

—

3.6

—

43

—

3.7

—

43

—

3.8

—

42

—

3.2

—

42

—

3.3

—

42

—

3.4

—

41

42

3.2

3.5

41

42

3.3

3.6

41

42

3.4

3.7

965

43

—

3.4

—

43

—

3.6

—

43

—

3.7

—

43

—

3.8

—

42

—

3.2

—

42

—

3.3

—

42

—

3.4

—

41

42

3.2

3.5

41

42

3.3

3.6

980

44

43

3.8

3.3

42

—

3.5

—

43

—

3.6

—

43

—

3.7

—

43

—

3.8

—

42

—

3.2

—

42

—

3.3

—

42

—

3.4

—

41

42

3.2

3.5

995

44

43

3.7

3.2

44

43

3.8

3.4

43

—

3.5

—

43

—

3.6

—

43

—

3.7

—

43

—

3.8

—

42

—

3.2

—

42

—

3.3

—

42

—

3.4

—

1010

44

—

3.6

—

44

43

3.7

3.3

44

43

3.8

3.4

43

—

3.5

—

43

—

3.6

—

43

—

3.7

—

43

—

3.8

—

42

—

3.2

—

42

—

3.3

—

1025

44

—

3.5

—

44

43

3.6

3.2

44

43

3.7

3.3

43

—

3.4

—

43

—

3.5

—

43

—

3.6

—

43

—

3.7

—

43

—

3.8

—

43

—

3.2

—

1040

44

—

3.4

—

44

—

3.5

—

44

43

3.6

3.2

44

43

3.7

3.3

43

—

3.4

—

43

—

3.5

—

43

—

3.6

—

43

—

3.7

—

43

—

3.8

—

1055

44

—

3.3

—

44

—

3.4

—

44

—

3.5

—

44

43

3.6

3.2

44

43

3.8

3.3

43

—

3.4

—

43

—

3.5

—

43

—

3.6

—

43

—

3.7

—

1070

44

—

3.2

—

44

—

3.3

—

44

—

3.4

—

44

—

3.5

—

44

43

3.7

3.2

44

43

3.8

3.3

43

—

3.4

—

43

—

3.5

—

43

—

3.6

—

1085

45

—

3.8

—

44

—

3.2

—

44

—

3.3

—

44

—

3.4

—

44

—

3.6

—

44

43

3.7

2.3

44

43

3.8

3.3

43

—

3.4

—

43

—

3.5

—

1100

45

—

3.7

—

45

—

3.8

3.4

44

—

3.2

—

44

—

3.4

—

44

—

3.5

—

44

—

3.6

—

44

43

3.7

3.2

44

43

3.8

3.3

43

—

3.4

—

—12—