Accessories, Wire feeders and tractors, Field installed options – Lincoln Electric IDEALARC IM10018-A User Manual

Page 24: Factory or field installed options

C-1

ACCESSORIES

C-1

IDEALARC® DC-600 VRD

WIRE FEEDERS AND TRACTORS

The IDEALARC® DC-600 VRD can be used to power

any of the following Lincoln Wire Feeders and

Tractors:

Semi-Automatic Wire Feeders:

DH-10

LN-9

LN-7

LN-9 GMA

LN-7 GMA

LN-23P

LN-742

LN-25

LN-8

LN-10

Automatic Wire Feeders:

NA-3

NA-5R

NA-5

Tractors:

LT-7 LT-56

FIELD INSTALLED OPTIONS

Remote Output Control (K775 or K857

with K864 Adapter)

An optional “remote out control” is available. The

K775 is the same remote control that is used on other

Lincoln power sources. The K775 consist of a control

box with 28 feet (8.5mm) of four conductor cable. This

connects to terminals 75,76, and 77 on the terminal

strip (T.S.1) and the case grounding screw so marked

with the symbol “ ” on the machine. These termi-

nals are located behind the hinged cover on the case

front. This control will give the same control as the

output control on the machine.

The K857 is similar to the K775, except the K857 has

a 6-pin MS-style connector. The K857 requires a

K864 adapter cable which connects to the 14-pin con-

nector on the case front.

Remote Control Adapter Cable (K864)

A "V" cable 12" (.30 m) long to connect a K857

Remote Control (6-pin connector) with an LN-7 wire-

feeder (14-pin connector) and the machine (14-pin

connector). If a remote control is used alone the wire-

feeder connection is then not used.

Undercarriages (K817P, K842)

For easy moving of the machine, optional undercar-

riages are available with polyolefin wheels (K817P) or

a platform undercarriage (K842) with mountings for

two gas cylinders at rear of welder.

Paralleling Kit (K1611-1)

Paralleling of two VRD models or a standard model

with a VRD model is not recommended.

Tig Module (K930-2)

Portable high frequency generator for AC/DC TIG

welding.

FACTORY OR FIELD INSTALLED

OPTIONS

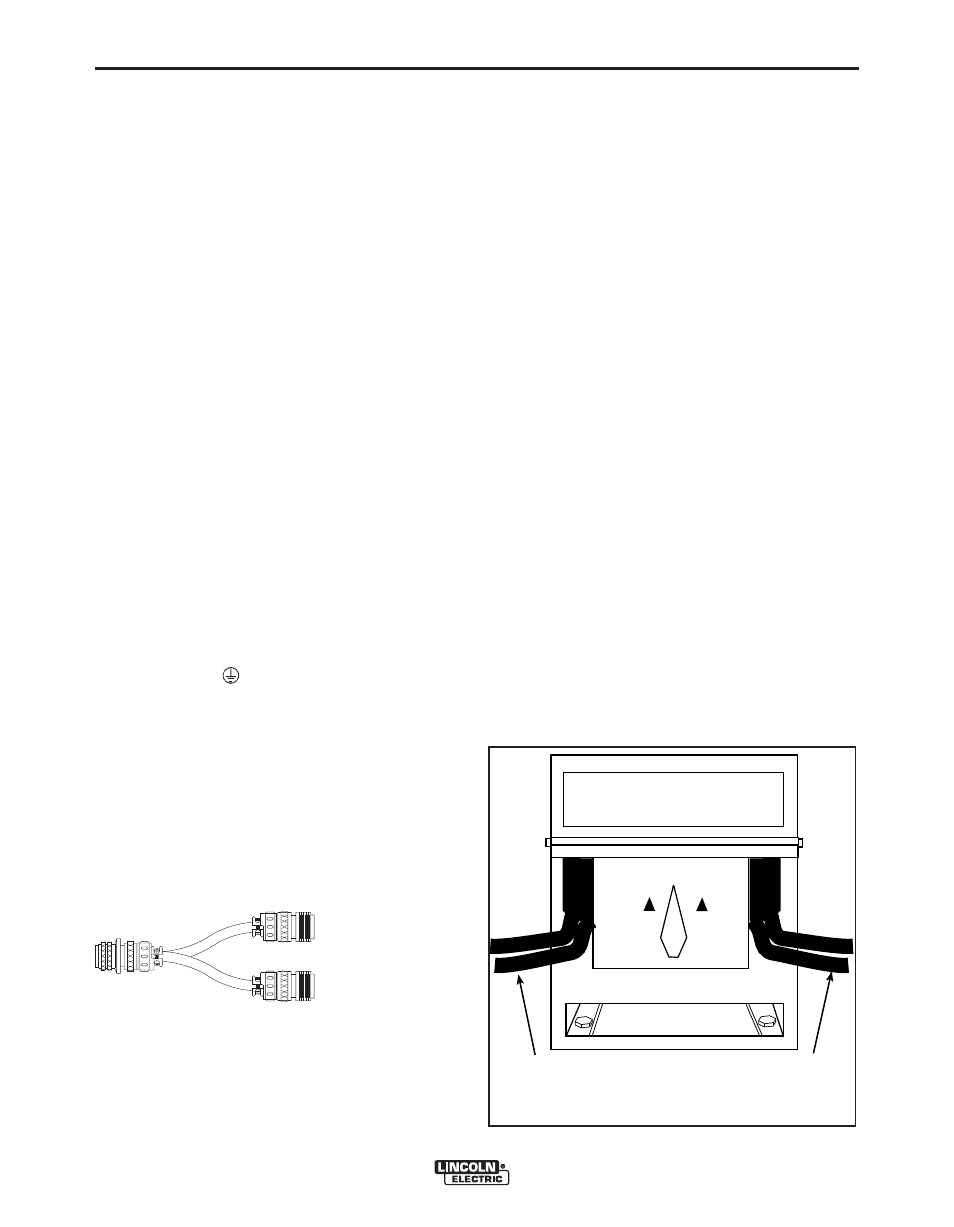

Multi-Process Switch (K804-1)

The MULTI-PROCESS SWITCH gives you the ability

to:

• Switch between "stick welding or air/carbon arc cut-

ting" and using a semi-automatic or automatic wire

feeder.

• Change the polarity of a semi-automatic or auto-

matic wire feeder without changing any electrical

cable connections.

See Figure C.1

FIGURE C.1 - MULTI-PROCESS SWITCH

STRAIGHT PLUG (14 PIN)

TO POWER SOURCE

CABLE RECEPTACLE (6 SOCKET)

CABLE RECEPTACLE (14 SOCKET)

TO: K857 REMOTE CONTROL

TO: LN-7 WIRE FEEDERS

S T R A I G H T P L U G ( 1 4 P I N )

T O P O W E R S O U R C E

C A B L E R E C E P T A C L E ( 6 S O C K E T )

C A B L E R E C E P T A C L E ( 1 4 S O C K E T )

T O : K 8 5 7 R E M O T E C O N T R O L

T O : L N - 7 W I R E F E E D E R S

–

+

WIRE

FEEDER

CABLES

STICK OR

AIR/CARBON

ARC CABLES

STICK OR

AIR

CARBON

ARC

+

-

–

+

WIRE

FEEDER

CABLES

STICK OR

AIR/CARBON

ARC CABLES

STICK OR

AIR

CARBON

ARC

+

-