Diagrams, Cv adapter – Lincoln Electric CV ADAPTER IM309-D User Manual

Page 35

E-6

DIAGRAMS

E-6

CV ADAPTER

-

+

CV ADAPTOR CONTROL LEADS

U

ELECTRICAL SYMBOLS

U

E

A

2

F

1

N

U

AC

W

ARE NOT COLOR CODED

LEAD 613 DOES NOT APPEAR

ON CV ADAPTOR UNITS BELOW 8785

*

R

ON ALL UNITS

Y

FLASHING DIODE

W

PER E1537

AC

U

TO ALTERNATOR

N

Y

(-)

B

N

TO ENGINE CIRCUIT

COPPER TERMINAL

TO WORK / POSITIVE

CV & VV OUTPUT TERMINAL

NEGATIVE CV OUTPUT TERMINAL

(+)

B

W

R

TO NEGATIVE BRUSH HOLDER

VV OUTPUT TERMINAL

ELECTRODE / NEGATIVE

RHEOSTAT

JOB SELECTOR

500

Y

120

CURRENT CONTROL

REACTOR

(REVERSING SWITCH)

POLARITY SWITCH

W

600

611

610

W

612

W

U

B

REMOTE CONTROL

(SWITCH SHOWN IN

LEAD COLOR CODE

G

602

25

509

503

U-BLUE

Y-YELLOW

25

Y

B

Y

R-RED

W-WHITE

N-BROWN

G-GREEN

B-BLACK

POS.

W

G

RECEPTACLE FOR

REMOTE CONTROL

RHEOSTAT

CB1

GROUND TERMINAL

WIDE SLOT

TO ALTERNATOR

LOCAL POSITION)

*

G

25

RESISTORS

R

613

NEG.

CV ADAPTER

CB2

G

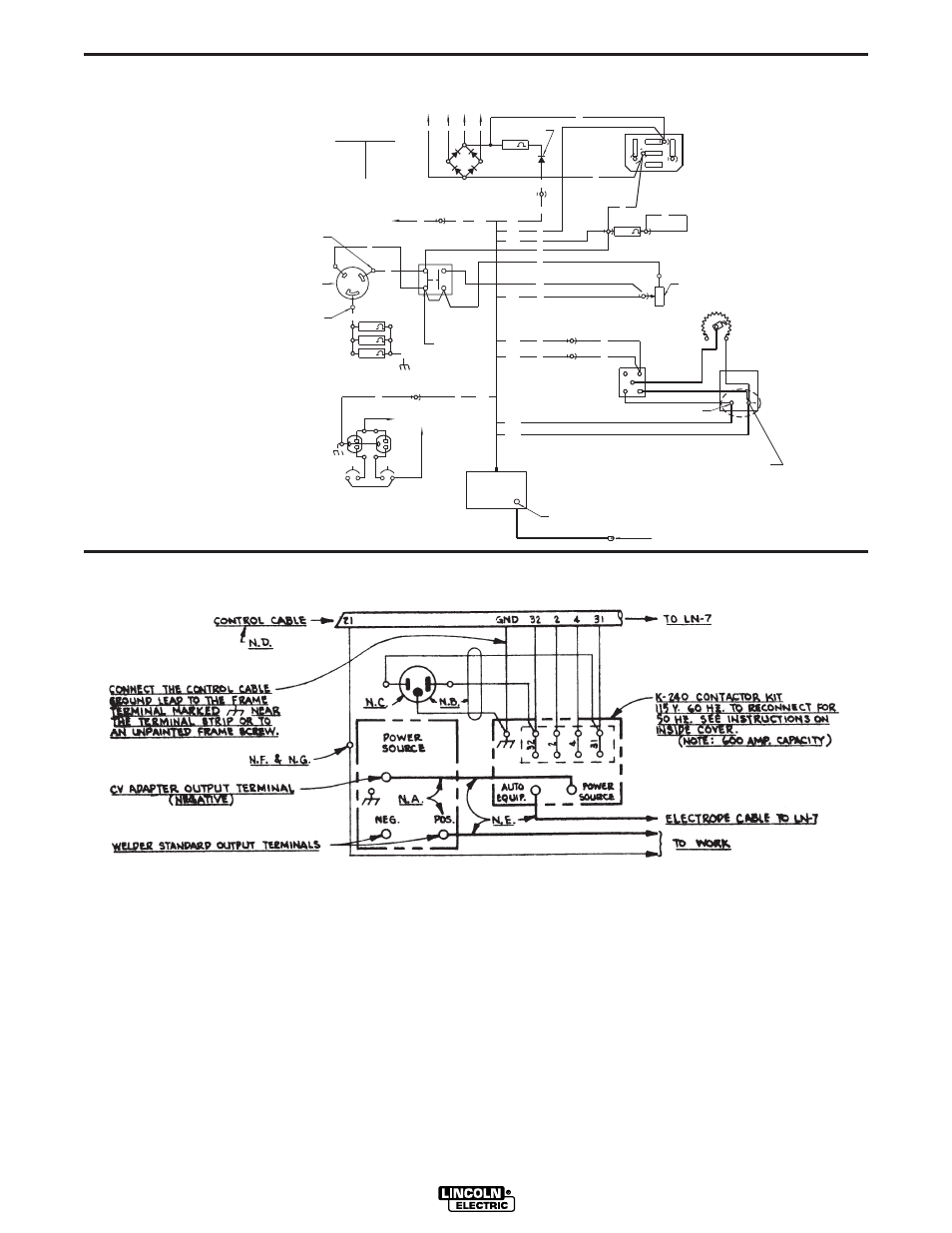

CONNECTION DIAGRAM — CV ADAPTER TO SAE-400 AND WELD’N AIR ENGINE WELDER Code 10362 AND 10665

S24466

B.01

N.A.

Connection shown for negative polarity. For positive polarity, reverse cables connected to output terminals.

N.B.

3 conductor #16 power cord physically suitable for the installation and plug rated at 115 volts 15 amperes AC.

N.C.

Plug into 115 volt AC receptacle on welder control panel or other 115 volt AC supply rated a minimum of 500 volt amperes.

N.D.

Leads #21 and GND. do not appear on LN-7

’

s with codes below 7026.

N.E.

Welding cables must be of proper capacity for the current and duty cycle on immediate and future applications.

N.F.

If LN-7 is equipped with a meter kit, extend lead 21 using #14 or larger insulated wire physically suitable for the installation. An

S16586-[ ] remote voltage sensing work lead is available for this purpose. Connect it directly to the work piece keeping it electrically

separate from the welding work lead circuit and connection. For convenience, this extended #21 lead should be taped to the welding

work lead.

N.G.

Tape up bolted connection.

CAUTION: Any speed up of the engine RPM by changing the governor setting or over-riding the throttle linkage will cause an increase in

the AC auxiliary voltage. If this voltage goes above 140 volts, the LN-7 control circuit will be damaged. The engine governor set-

ting is pre-set at the factory

—

do not adjust above RPM specifications listed in engine welder operating manual.

CONNECTION DIAGRAM — LN-7 WIRE FEEDER TO ENGINE WELDERS WITH

115 VOLT AC AUXILIARY POWER, CV ADAPTER AND K240 CONTACTOR KIT

S17525

7-15-83