Installation, Warning caution – Lincoln Electric CV ADAPTER IM309-D User Manual

Page 15

B-6

INSTALLATION

CV ADAPTER

B-6

POLARITY OF THE STANDARD OUTPUT TERMI-

NALS MUST BE AS STATED IN STEP 14 AND THE

MAXIMUM OPEN CIRCUIT VOLTAGE WITH THE

LOWER MODE SWITCH IN CV POSITION MUST

BE AS STATED IN STEP 15 BEFORE PLACING

THE UPPER MODE SWITCH IN CV POSITION.

FAILURE TO HAVE THE CORRECT POLARITY

AND VOLTAGE BEFORE PLACING THE UPPER

MODE SWITCH IN CV POSITION WILL RESULT IN

DAMAGE TO THE CV ADAPTER.

14. To check the VV output, place both CV/VV switch-

es on the CV Adapter in the “VV” position. If welder

has remote control, set remote control switch to

local position. Start the SA-250 and place idler

control in “high” position. Use a DC voltmeter

across the standard output terminals to check the

output polarity. If it is incorrect, recheck Steps 4

through 12. Open circuit voltage should be about

43-53 volts DC when the Fine Current Adjustment

is set to minimum and 93-100 volts DC when set at

maximum. These voltages may be higher if read-

ings are taken when welder is cold.

15. To check the CV output, place only the lower

switch in the “CV” position. This may be done while

the engine is running as long as no welding is

being done. Voltage between the positive output

terminal and the CV output terminal should be 7-12

volts when the CV Adapter voltage control is at

minimum setting and 36-48 volts at maximum set-

ting.

16. If output varies greatly from that specified in Steps 14

and 15, check wiring. If this does not solve problem,

refer to Troubleshooting Section of manual.

K384 CV ADAPTER TO SA-250 ENGINE

WELDER WITH DC AUXILIARY OUTPUT

NOTE: Before installing CV Adapter, start engine welder

and use a DC voltmeter to check the polarity of the red

and black leads connected to the auxiliary power recep-

tacle. The red lead should be negative and the black lead

should be positive. If the polarity is not correct, refer to

engine welder operating manual for instructions to flash

the exciter to obtain the correct polarity.

• TURN THE ENGINE OFF WHILE INSTALLING THIS

ACCESSORY.

• KEEP HANDS, HAIR, CLOTHING AND TOOLS

AWAY FROM MOVING PARTS WHEN STARTING

OR OPERATING ENGINE.

1. Remove roof assembly and bracket cover (cover on

top and at rear of generator).

2. Drill two holes in fuel tank rail opposite output termi-

nals as in Figure 8, if holes are not in unit.

3. Mount CV Adapter (unit with “SA” above code num-

ber) to the support holes. Use the one stud on the

Adapter case, a spacer, lockwasher, and nut on one

end and 3/8-16 x 1 hex head bolt and hardware on

the other end as shown in Figure 9. In mounting the

unit, be sure the fuel line and choke cable are not

pinched.

WARNING

CAUTION

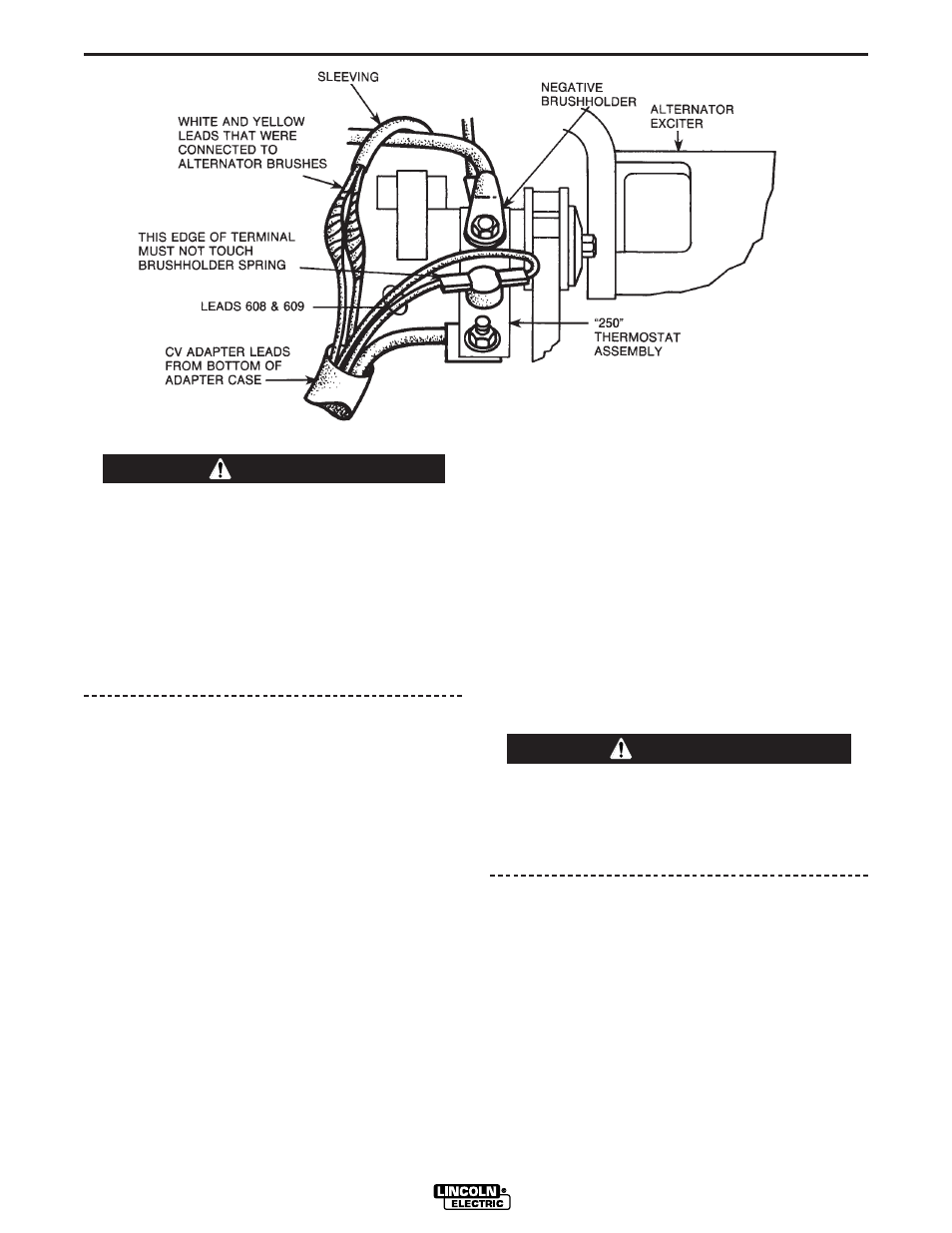

FIGURE 7 – View of Negative Generator Brushholder after Bracket Cover is Removed.