Features and benefits of liebert drycoolers, Heat rejection module, Low noise level – Liebert EMERSON 60 HZ User Manual

Page 6: Easy installation and service, Maximum reliability, Table 1 drycooler performance data, Eatures, Enefits, Iebert, Rycoolers

2

F

EATURES

AND

B

ENEFITS

OF

L

IEBERT

D

RYCOOLERS

Heat Rejection Module

The low-profile direct-drive propeller-fan type drycoolers utilize optimum circuitry to balance the heat rejec-

tion of the corresponding load. Constructed of aluminum with a copper-tube aluminum coil, the unit is quiet

and corrosion resistant.

Low Noise Level

All Liebert drycoolers are designed to operate at a minimal noise level. This is accomplished as the result of

the Liebert fan blade design combined with a cabinet structure that minimizes air resistance. Quiet-Line

models use low speed motors to achieve the quietest unit available.

Easy Installation and Service

The heat rejection module is quickly and easily installed, because all internal wiring is completed at the fac-

tory with only electrical connections to be made at the job site.

Maximum Reliability

Because these units are factory wired and tested, start-up problems are eliminated, and reliability of the

overall system is greatly increased.

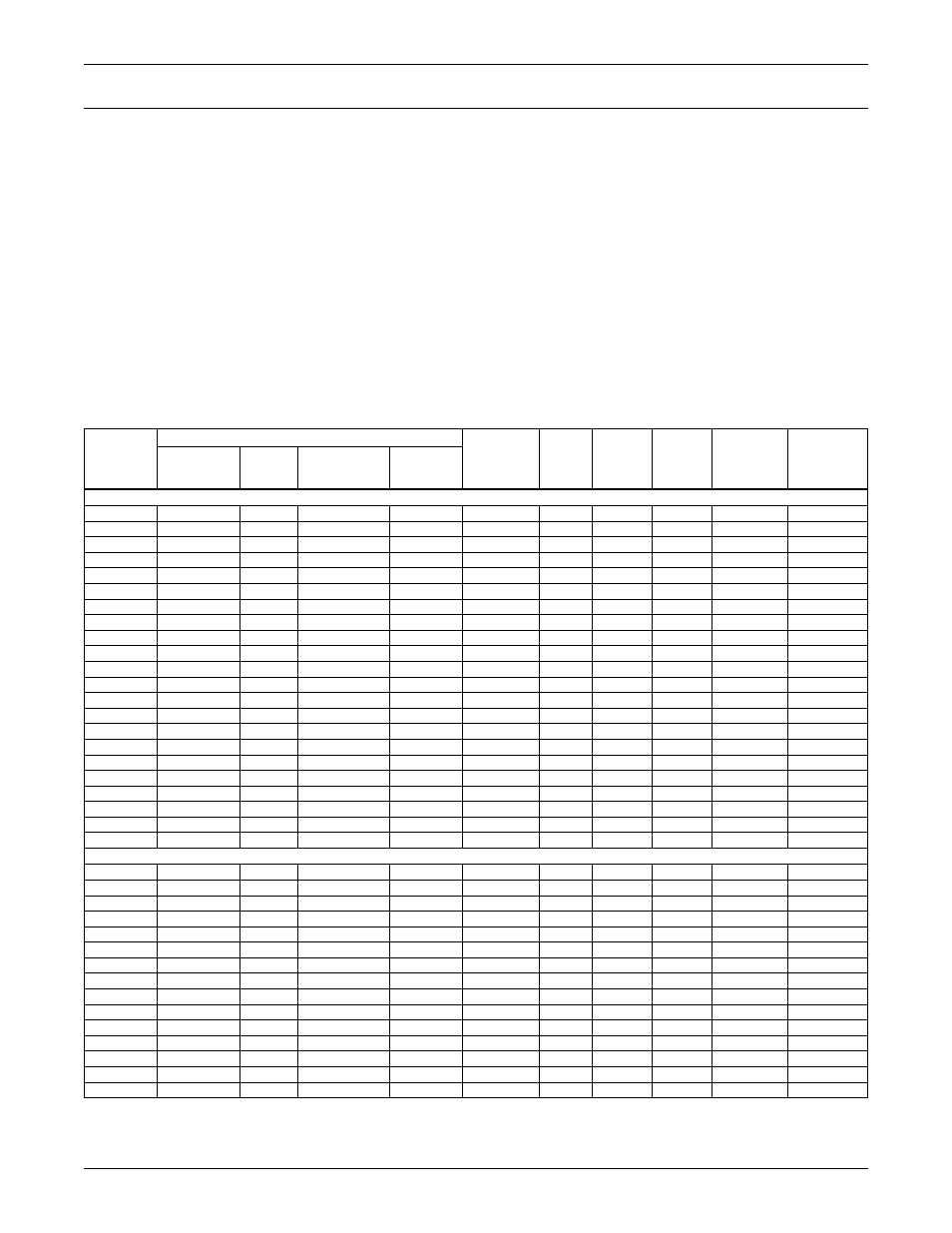

Table 1

Drycooler performance data

Model

Number

*D**

Standard Unit Data

Conn. +

Size

In/Out

#

26"

Fans

Air

Flow

(CFM)

dBA**

Internal

Volume

(gal.)

Shipping

Weight

(lbs.)

Total

Heat Rej.

@ 25 ITD

Flow

Rate

(gpm)

Press.

Drop

(Ft. Water)

#

Internal

Circuits

Standard Models

033

37950

10

9.1

4

3/4

1

7200

72.5

1.2

390

069

67040

20

8.9

8

1-1/4

1

6870

72.5

2.4

410

092

92380

30

8.6

12

1-1/2

1

6600

72.5

3.7

430

109

108760

40

8.1

16

2

1

6300

72.5

4.9

450

112

118200

40

10.1

16

2

1

6090

72.5

5.8

470

139

134100

40

7.1

16

2

2

13700

75.5

4.8

565

174

173400

40

10.5

16

2

2

13300

75.5

6.9

605

197

197000

40

13.9

16

2

2

12645

75.5

9.0

645

225

231000

65

10.9

26

2

2

12200

75.5

11.1

685

260

260200

60

10.1

24

2

3

19900

77.3

10.0

826

310

310500

80

9.8

32

2

3

19000

77.3

13.1

886

350

353000

80

14.6

32

2

3

17400

77.3

19.4

946

352

328400

60

12.9

24

2

4

24800

78.5

13.1

1070

419

393600

80

12.7

32

2

4

23650

78.5

17.4

1160

466

441200

100

12.7

40

2-1/2

4

22800

78.5

22.0

1250

491

469100

120

12.8

48

2-1/2

4

21700

78.5

26.3

1340

620

621000

160

9.8

64

2) 2-1/8

6

37900

80.3

27.0

1770

650

652100

130

15.2

52

2) 2-1/8

6

36500

80.3

33.1

1830

700

706100

160

14.6

64

2) 2-1/8

6

34800

80.3

39.3

1890

790

787200

160

12.7

64

2) 2-1/8

8

47300

81.5

35.0

2320

880

882000

200

12.7

80

4) 2-1/8

8

45500

81.5

44.4

2500

940

938200

240

12.5

96

4) 2-1/8

8

43400

81.5

52.6

2680

Quiet-Line Models

040

44435

20

8.8

8

1-1/4

1

3110

56.5

2.4

410

057

57000

30

8.6

12

1-1/2

1

2990

56.5

3.7

430

060

62790

40

8.1

16

2

1

2840

56.5

4.9

450

080

88865

40

7.0

16

2

2

6220

59.5

4.8

565

111

110765

40

10.4

16

2

2

5980

59.5

6.9

605

121

120800

40

13.7

16

2

2

5680

59.5

9.0

645

158

166150

60

10.0

24

2

3

8970

61.3

10.0

825

173

184850

80

9.7

32

2

3

8520

61.3

13.1

885

178

186040

80

14.5

32

2

3

7440

61.3

19.4

950

205

218980

60

12.9

24

2

4

11680

62.5

13.1

1070

248

248420

80

12.5

32

2

4

11360

62.5

17.4

1160

347

369100

160

9.8

64

2) 2-1/8

6

17040

64.3

27.0

1940

356

371800

160

14.6

64

2) 2-1/8

6

14880

64.3

39.3

2060

453

496000

60

12.6

64

2) 2-1/8

8

22720

65.5

35.0

2550

498

505230

240

12.4

96

4) 2-1/8

8

19840

65.5

52.6

2910

Standard data based on 95°F EAT, 120°F EFT, 40% EG.

** Sound Level - dBA @ 5 feet.

+ Connections 2" and smaller are FPT; 2-1/8" are ID. SWEAT