Maintenance schedule – Lochinvar KNIGHT XL 400 User Manual

Page 7

2

Maintenance schedule

(continued)

7

3. Fill with fresh water until the water begins to pour out

of the drain.

4. Replace the cap. Press the cap onto the trap until the

cap makes contact with the drain.

5. Replace the retaining screw.

ƽ WARNING

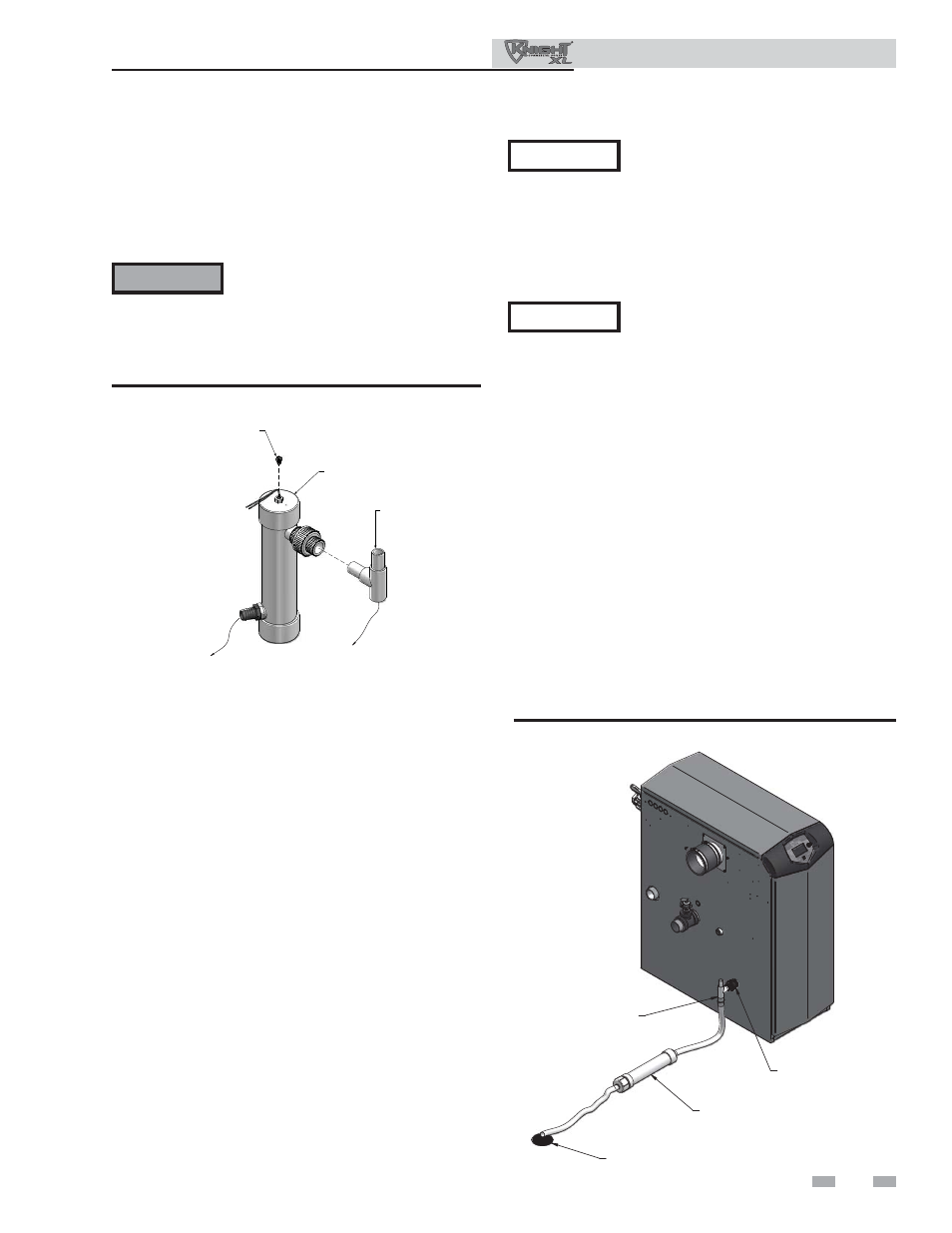

The condensate trap (FIG. 2-1) must

be filled with water during all times

of boiler operation to avoid flue gas

emission from the condensate drain line.

Failure to fill the trap could result in

severe personal injury or death.

PVC TEE ASSEMBLY

(FACTORY SUPPLIED)

TO FLOOR

DRAIN

2” PVC CAP WITH

BLOCKED DRAIN SWITCH

RETAINING

SCREW

CONDENSATE FROM

HEAT EXCHANGER

Figure 2-1 Condensate Trap

Condensate disposal

1. This boiler is a high efficiency appliance that produces

condensate.

2. The side of the boiler has a 1/2 inch PVC union for

connection of a 1/2 inch PVC pipe (FIG. 2-2).

3. Slope condensate tubing down and away from the

boiler into a drain or condensate neutralizing filter.

Condensate from the Knight XL will be slightly acidic

(typically with a pH from 3 to 5). Install a neutralizing

filter if required by local codes. Call your qualified

service technician to inspect the boiler and system.

A Neutralizer Kit is available from the factory (Kit 3087

for Models 400 - 501 and Kit 30002 for Models 601 -

801). Call your qualified service technician to install.

4. Install the 1/2 inch PVC tee assembly (shipped with the

unit) as shown in FIG. 2-2. Call your qualified service

technician to inspect the boiler and system.

5. Leave the top of the 1/2 inch tee OPEN. This is needed

as a vacuum break.

6. Do not expose condensate line to freezing temperatures.

7. Use only plastic tubing or piping as a condensate drain

line (FIG. 2-2).

Use materials approved by the authority

having jurisdiction. In the absence of

other authority, PVC and CPVC pipe

must comply with ASTM D1785 or D2845.

Cement and primer must comply with

ASME D2564 or F493. For Canada use

CSA or ULC certified PVC or CPVC pipe,

fittings, and cement.

8. A condensate removal pump is required if the boiler is

below the drain. When installing a condensate pump,

select one approved for use with condensing boilers

and furnaces. The pump should have an overflow

switch to prevent property damage from condensate

spillage. Call your qualified service technician to inspect

the boiler and system.

NOTICE

NOTICE

To allow for proper drainage on large

horizontal runs, a second line vent may

be required and tubing size may need to

increase to 1 inch.

The condensate line must remain

unobstructed, allowing free flow of

condensate. If condensate is allowed to

freeze in the line or if the line is obstructed

in any other manner, condensate can exit

from the boiler tee, resulting in potential

water damage to property. Call your

qualified service technician to inspect

the boiler and system.

1/2" PVC UNION

(FACTORY SUPPLIED)

NEUTRALIZER KIT

FLOOR DRAIN OR

DRAIN PAN

1/2" PVC TEE ASSEMBLY

(FACTORY SUPPLIED)

Figure 2-2 Condensate Disposal

User’s Information Manual