Operation, Pulse welding procedure guidelines – Lincoln Electric MIG PULSER IM555 User Manual

Page 14

B-4

OPERATION

B-4

MIG PULSER

PULSE WELDING PROCEDURE

GUIDELINES

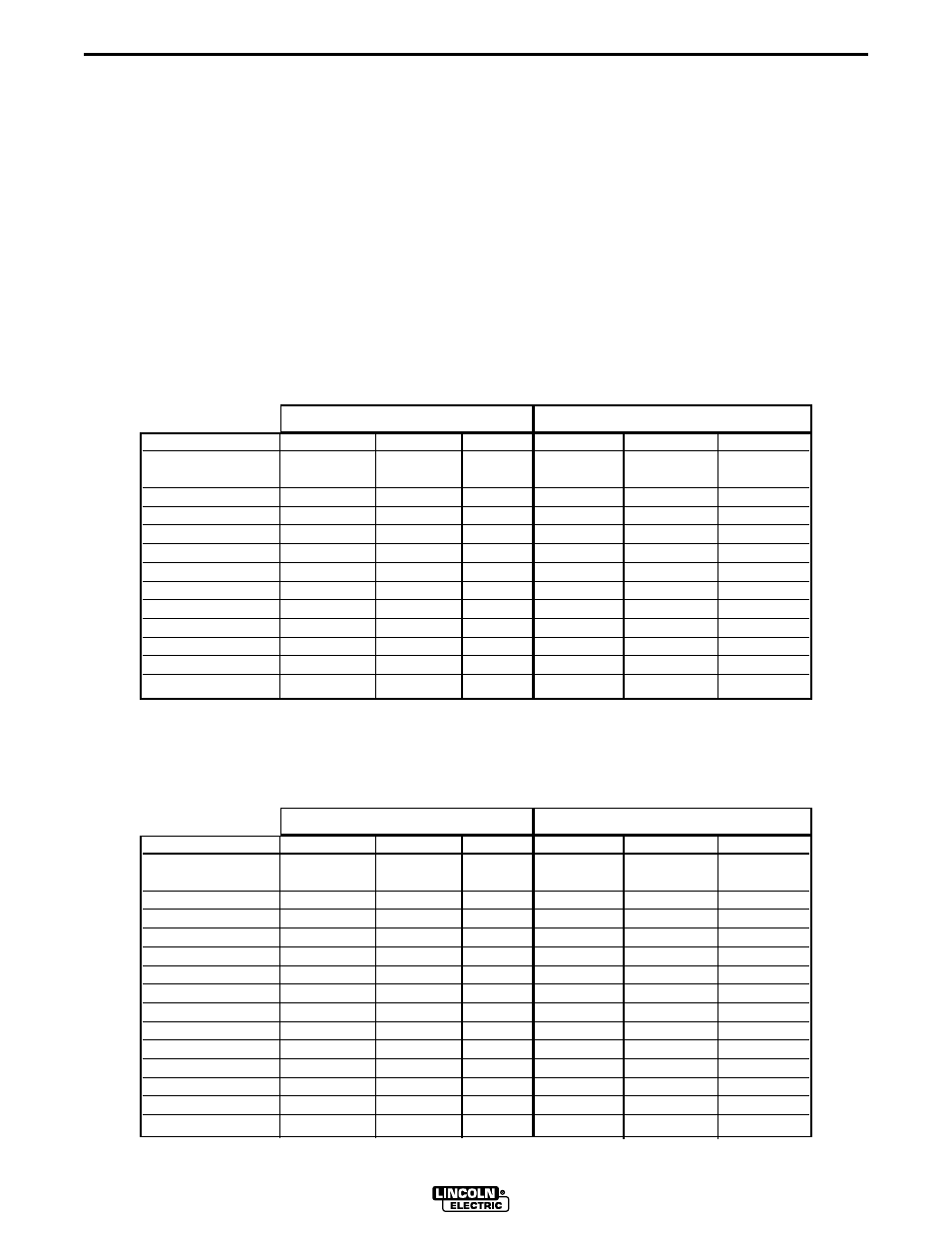

Tables B.2 and B.3 list initial settings guidelines for

pulse welding with the MIG PULSER for Stainless

Steel and Mild Steel. These settings are intended as

suggestions only. The serviceability of a product or

structure utilizing this type of information is and must

be the sole responsibility of the builder/user. Many

variables beyond the control of The Lincoln Electric

Company affect the results obtained in applying this

type of information. These variables include, but are

not limited to, welding procedure, plate chemistry and

temperature, weldment design, fabrication methods

and service requirements.

These settings were developed for joints in the flat or

horizontal position. Out-of-position work will require

adjustments to these procedures.

To tighten or stiffen the arc, try decreasing the Peak

setting. To widen or soften the arc, try increasing the

Peak setting.

Wire Feed Speed

Peak

Bkgnd

Arc Length

Peak

Bkgnd

Arc Length

135 IPM

Low

Norm

2

--

--

--

150

Low

Norm

3.5

Med

Norm

4.5

200

Low

Norm

5

Hi

Norm

5.5

250

Med

Norm

5.5

Hi

Norm

6.5

300

Med

Norm

6

Hi

Norm

7

350

Med

Norm

6.5

Hi

Norm

7.5

400

Med

Norm

7

Hi

Norm

7.7

450

Med-Hi

Norm

7.5

Hi

Norm

8

500

Med-Hi

Norm

8

Hi

Norm

8.1

550

Med-Hi

Norm

8.5

--

--

--

600

Med-Hi

Norm

9

--

--

--

650

Med-Hi

Norm

9.5

--

--

--

.035 E308LSi 98/2 Ar/O

2

.045 E308LSi 98/2 Ar/O

2

Table B.2 Procedure Guidelines for Stainless Steel

Table B.3 Procedure Guidelines for Mild Steel

Wire Feed Speed

Peak

Bkgnd

Arc Length

Peak

Bkgnd

Arc Length

100 IPM

--

--

--

Low

Norm

5.1

125

--

--

--

--

--

--

150

Low

Norm

4.5

Med

Norm

6.2

200

Low

Norm

5.5

Med

Norm

7

250

Low

Norm

6

Med

Norm

7.5

300

Low

Norm

6.4

Med

Norm

8

350

Low

Norm

7

Med

Norm

8.5

400

Low

Norm

7.5

Med

Norm

9

450

Low

Norm

8.1

Med

Norm

9.5

500

Med

Norm

8.2

--

--

--

550

Med

Norm

8.4

--

--

--

600

Med

Norm

8.5

--

--

--

650

Med

Norm

9

--

--

--

700

Med

Norm

9.5

--

--

--

.035 L-56 90/10 Ar/CO

2

.045 L-56 90/10 Ar/CO

2

JAN97