Operation, Welding capability, Limitations – Lincoln Electric MIG PULSER IM555 User Manual

Page 12

B-2

OPERATION

B-2

DESIGN FEATURES AND ADVANTAGES

•Simple controls make this unit easy to set up and

adjust.

•The control algorithm is adaptive — it responds to

changes in stick-out and gun angle while maintaining

a stable arc.

•Designed to the IEC-974-1 standard.

•Attractive, rugged case includes carrying handle and

rubber feet.

•Unit is supplied with one bracket for mounting to the

V300, and one “universal” bracket for mounting to ver-

tical or horizontal surfaces.

WELDING CAPABILITY

The V300 must be derated when used for GMAW-P

with the MIG Pulser.

High peak currents required by

the pulse process increase the power source heating,

thus reducing the rated output. The V300 Pro and

V300-I (with three phase input) are presently rated 300

amps at 60% duty cycle. When pulsing, the ratings of

both models must be reduced to 250 amps at 60%.

The single phase rating of the V300 PRO must be

reduced from 250 amps/60% to 200 amps/60% when

pulsing. The single phase rating of the V300-I must be

reduced from 200 amps/60% to 150 amps/60% when

pulsing. Refer to Table B.1.

LIMITATIONS

The V300/MIG Pulser combination cannot be used

with long work and electrode leads. The total length of

the welding leads (work lead length plus electrode lead

length) should not exceed 50 feet.

[If longer cables

are used, refer to the

Output Cables for Pulse

Welding section in the Installation chapter for limita-

tions.]

The Magnum Spoolgun/MIG Pulser combination will

not run low wire feed speed, fine wire aluminum pro-

cedures well. These wires are best run in a spray

mode; GMAW-P offers few advantages in those areas.

The voltage meter on the wire feeder will not display

voltage due to the lack of a 21 lead in the feeder con-

nection.

The V300 with a MIG Pulser may not be suitable for

use near a high frequency arc starter (such as is found

in a TIG welding power source or a plasma cutter).

Refer to

High Frequency Interference Protection

section in the Installation section of this manual.

Problems with the trigger interlock may be experienced

when using the MIG PULSER with an LN9-GMA that

has a L7265-2 power board.

MIG PULSER

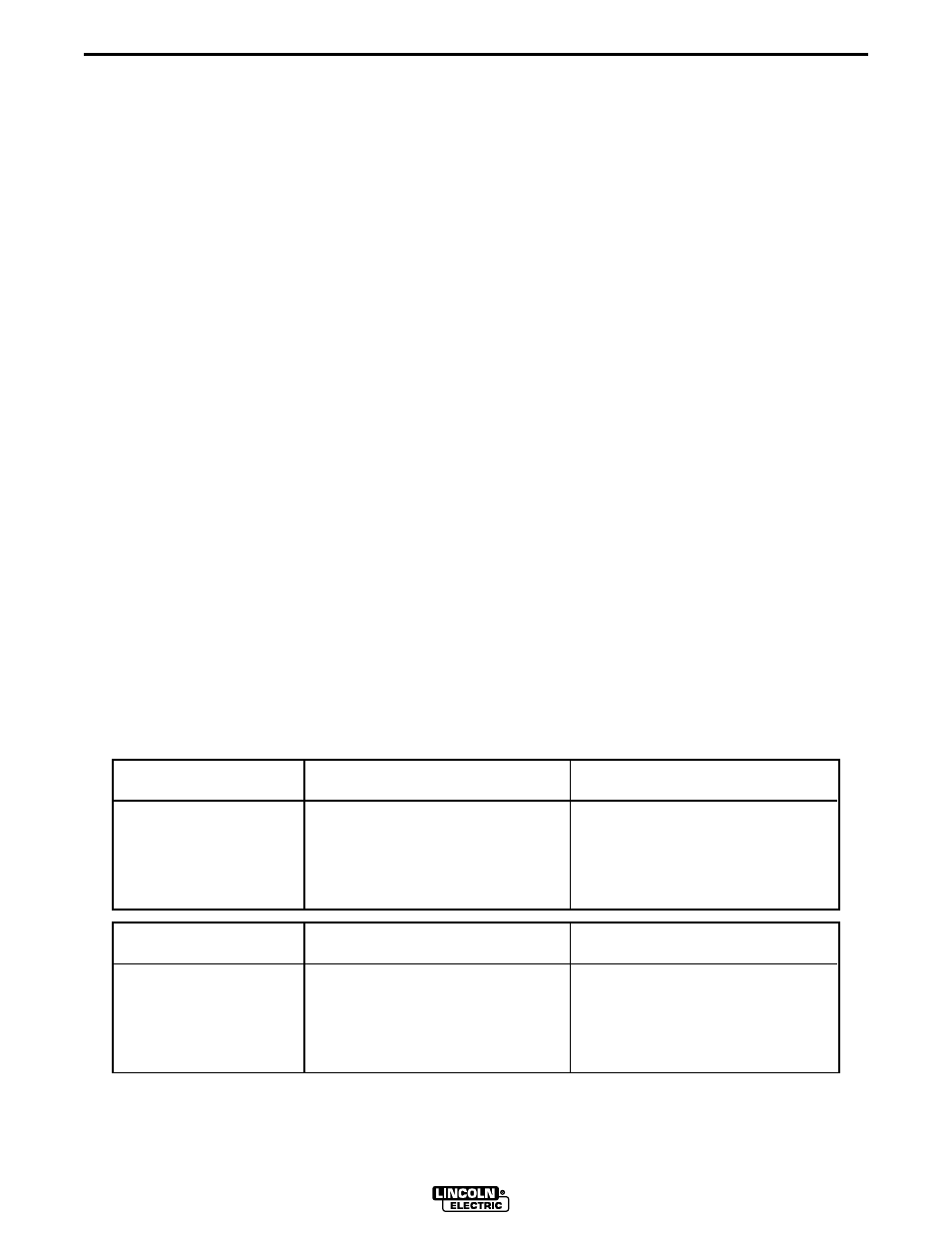

V300 PRO

Standard V300 PRO Rating

V300 PRO Rating when Using

Input Power

(without MIG Pulser)

MIG Pulser

3 Phase, 60 Hz

300 Amps / 60 % Duty Cycle

250 Amps / 60 % Duty Cycle

1 Phase, 60 Hz

250 Amps / 60% Duty Cycle

200 Amps / 60% Duty Cycle

TABLE B.1 V300 OUTPUT DERATING

V300-I

Standard V300-I Rating

V300-I Rating when Using

Input Power

(without MIG Pulser)

MIG Pulser

3 Phase, 50 Hz

300 Amps / 60 % Duty Cycle

250 Amps / 60 % Duty Cycle

1 Phase, 50 Hz

200 Amps / 60% Duty Cycle

150 Amps / 60% Duty Cycle

JAN97