Caution, Electrical – Lennox International Inc. G24-200 User Manual

Page 27

Page 27

Electrical

CAUTION

Electrostatic discharge can affect electronic com-

ponents. Take precautions during furnace installa-

tion and service to protect the furnace’s electronic

controls. Precautions will help to avoid control ex-

posure to electrostatic discharge by putting the fur-

nace, the control and the technician at the same

electrostatic potential. Neutralize electrostatic

charge by touching hand and all tools on an un-

painted unit surface, such as the gas valve or blow-

er deck, before performing any service procedure.

Refer to figure 15, 16, and 17 for field wiring and figures 18

and 19 for schematic wiring diagram and troubleshooting.

1 − Select circuit protection and wire size according to re-

quirements listed on unit rating plate.

2 − Install a separate disconnect switch (protected by ei-

ther fuse or circuit breaker) near the unit so power can

be turned off for servicing.

3 − Make power supply wire connections at unit make-up

boxes (both left and right side boxes are provided).

4 − Install the room thermostat according to the instruc-

tions provided with the thermostat and make connec-

tions according to the appropriate field wiring

diagram. Install a field-provided 150 ohm, 10 watt re-

sistor (Lennox part number P−8−6256) in two-stage

applications when using an electro-mechanical ther-

mostat.

5 − All applications require a control transformer to power

the furnace’s 24 volt circuit. In all applications except

those where a 208/230 volt power supply is used, an

autotransformer is required to power each of the in-

duced draft blowers. These transformer(s) are pro-

vided in the drive kit which has been selected for use

with the furnace. Transformer part numbers and volt-

ages are given in table 10.

Install the transformer(s) in the control box using the

holes pre-drilled for them.

Select a field wiring diagram according to the power

supply voltage and phase being used (see figure 15,

16, or 17), and make the wiring connections between

the transformers and the furnace.

6 − Select a field wiring diagram according to the power

supply voltage and phase being used (see figure 15,

16, or 17), and make wiring connections between the

blower motor and the furnace. The connecting wires

are provided in the drive kit.

7 − An accessory relay (K109) is provided with the

G24−200 furnace. Any accessory with a rated voltage

equal to the supply voltage can be connected to termi-

nal 5" of this relay. The relay is energized with the

blower.

8 − To add an accessory which is energized on a heating

demand (such as a humidifier), a relay with coil wired

to terminal W1" of the TB1 terminal strip must be add-

ed.

9 − The TB1" terminal strip includes a terminal for econo-

mizer connection. See the field wiring diagrams.

10 − Electrically ground the unit according to local codes or,

in the absence of local codes, according to the current

National Electric Code (ANSI/NFPA No. 70) for the

USA or current Canadian Electric Code part 1 (CSA

standard C22.1) for Canada.

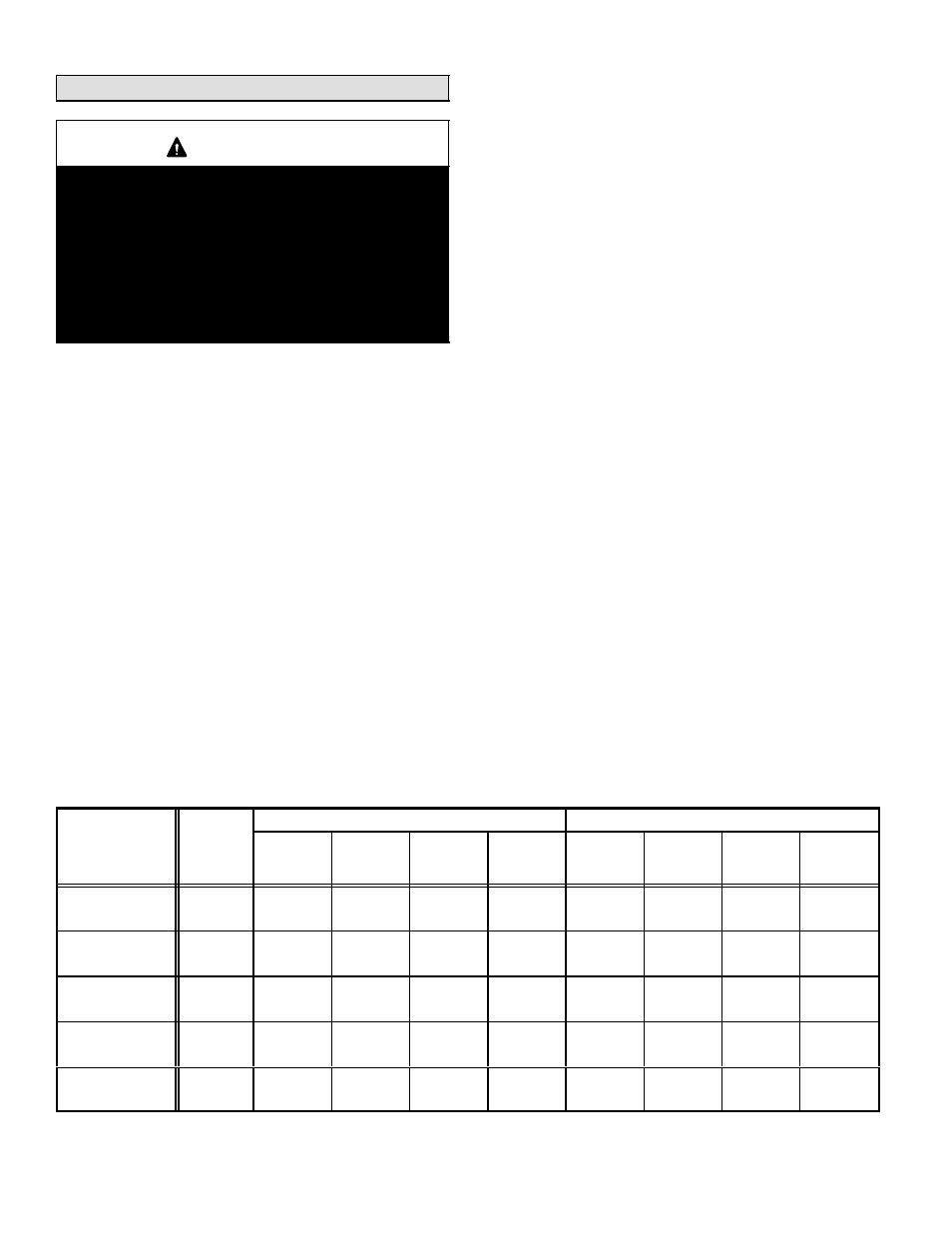

TABLE 10

DRIVE KIT TRANSFORMER VOLTAGES AND PART NUMBERS

Furnace

Supply

**Induced Draft Blower Autotransformers

Control Circuit Transformer

Drive Kit

Model No.

Supply

Voltage,

Phase,

Frequency

Transformer

Part Number

& (Quantity)

Wiring

Diagram

Designation

Input

Voltage

Output

Voltage

Transformer

Part Number

Wiring

Diagram

Designation

Primary

Voltage

Secondary-

Voltage

DKG24−200−1

120v,

1ph, 60hz

54G5201*

(2)

T3, T13

115*

230*

LB−66256G

(99K0601)

T1

120

24

DKG24−200−2

208/230v,

1ph, 60hz

− − − −

− − − −

− − − −

− − − −

LB−66256G

(99K0601)

T1

208 or 240

24

DKG24S−200−3,

DKG24−200−6

208/230v,

3ph, 60hz

− − − −

− − − −

− − − −

− − − −

LB−66256K

(13H2801)

T1

208 or 240

24

DKG24S−200−4,

DKG24−200−7

460v,

3ph, 60hz

54G5201

(2)

T3, T13

460

230

LB−66256H

(51H7901)

T1

480

24

DKG24S−200−5,

DKG24−200−8

575v,

3ph, 60hz

54G3101

(2)

T3, T13

575

230

LB−66256J

(66J5401)

T1

600

24

*Note − This transformer has a nominal 230 volt output rating and a 460 volt input rating; however, when wired to the furnace as shown in figure 15, a 115 volt input will produce a 230

volt output.

**Note − The induced draft blowers are rated at 230 volts, single phase, 60 hz.