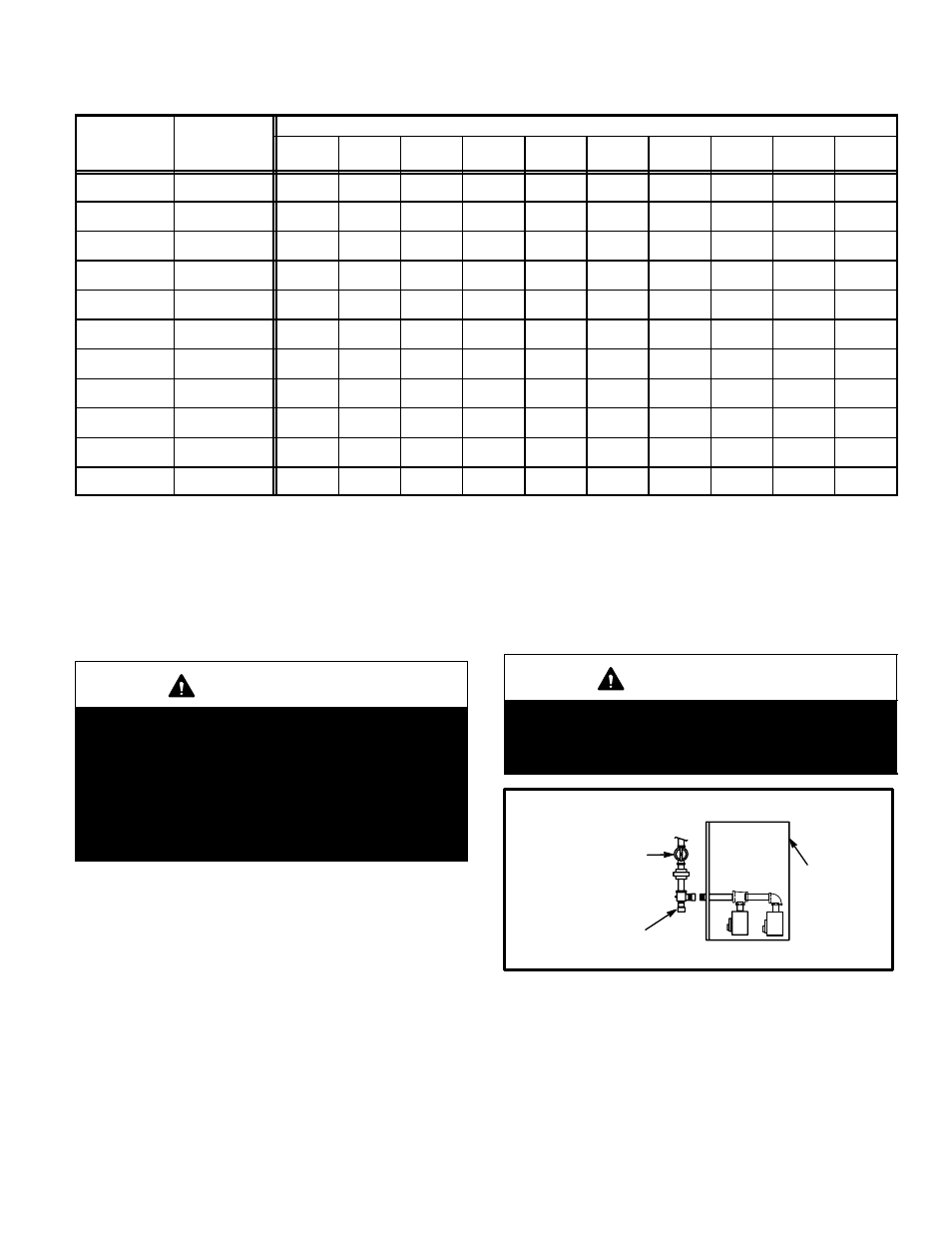

Warning, Important, Page 26 table 9 gas pipe capacity − ft – Lennox International Inc. G24-200 User Manual

Page 26: Hr (kl/hr), Figure 14

Page 26

TABLE 9

GAS PIPE CAPACITY − FT

3

/HR (KL/HR)

Nominal

Internal

Length of Pipe - Feet (m)

Nominal

Iron Pipe Size

Inches(mm)

Internal

Diameter

Inches(mm)

10

(3.048)

20

(6.096)

30

(9.144)

40

(12.192)

50

(15.240)

60

(18.288)

70

(21.336)

80

(24.384)

90

(27.432)

100

(30.480)

1/4

(6.35)

.364

(9.246)

43

(1.13)

29

(.82)

24

(.68)

20

(.57)

18

(.51)

16

(.45)

15

(.42)

14

(.40)

13

(.37)

12

(.34)

3/8

(9.53)

.493

(12.522)

95

(2.69)

65

(1.84)

52

(1.47)

45

(1.27)

40

(1.13)

36

(1.02)

33

(.73)

31

(.88)

29

(.82)

27

(.76)

1/2

(12.7)

.622

(17.799)

175

(4.96)

120

(3.40)

97

(2.75)

82

(2.32)

73

(2.07)

66

(1.87)

61

(1.73)

57

(1.61)

53

(1.50)

50

(1.42)

3/4

(19.05)

.824

(20.930)

360

(10.19)

250

(7.08)

200

(5.66)

170

(4.81)

151

(4.28)

138

(3.91)

125

(3.54)

118

(3.34)

110

(3.11)

103

(2.92)

1

(25.4)

1.049

(26.645)

680

(919.25)

465

(13.17)

375

(10.62)

320

(9.06)

285

(8.07)

260

(7.36)

240

(6.80)

220

(6.23)

205

(5.80)

195

(5.52)

1−1/4

(31.75)

1.380

(35.052)

1400

(39.64)

950

(26.90)

770

(21.80)

660

(18.69)

580

(16.42)

530

(15.01)

490

(13.87)

460

(13.03)

430

(12.18)

400

(11.33)

1−1/2

(38.1)

1.610

(40.894)

2100

(59.46)

460

(41.34)

1180

(33.41)

990

(28.03)

900

(25.48)

810

(22.94)

750

(21.24)

690

(19.54)

650

(18.41)

620

(17.56)

2

(50.8)

2.067

(52.502)

3950

(111.85)

2750

(77.87)

2200

(62.30)

1900

(53.80)

1680

(47.57)

1520

(43.04)

1400

(39.64)

1300

(36.81)

1220

(34.55)

1150

(32.56)

2−1/2

(63.5)

2.469

(67.713)

6300

(178.39)

4350

(123.17)

3520

(99.67)

3000

(84.95)

2650

(75.04)

2400

(67.96)

2250

(63.71)

2050

(58.05)

1950

(55.22)

1850

(52.38)

3

(76.2)

3.068

(77.927)

11000

(311.48)

7700

(218.03)

6250

(176.98)

5300

(150.07)

4750

(134.50)

4300

(121.76)

3900

(110.43)

3700

(104.77)

3450

(97.69)

3250

(92.03)

4

(101.6)

4.026

(102.260)

23000

(651.27)

15800

(447.39)

12800

(362.44)

10900

(308.64)

9700

(274.67)

8800

(249.18)

8100

(229.36)

7500

(212.37)

7200

(203.88)

6700

(189.72)

NOTE − Capacity given in cubic feet (m

3

) of gas per hour and based on 0.60 specific gravity gas.

Leak Check

After gas piping is completed, carefully check all piping

connections (factory- and field-installed) for gas leaks. Use

a leak detecting solution or other preferred means.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could

result in serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifi-

cally for the detection of leaks to check all connec-

tions. A fire or explosion may result causing proper-

ty damage, personal injury or loss of life.

NOTE − In case emergency shutdown is required, shut off

the main manual gas valve and disconnect the main power

to the furnace. These devices should be properly labeled

by the installer.

The furnace must be isolated from the gas supply system

by closing its individual manual shut-off valve during any

pressure testing of the gas supply system at pressures

equal to or less than 1/2 psig (3.48 kPa).

IMPORTANT

When testing pressure of gas lines, gas valve must

be disconnected and isolated. See figure 14. Gas

valves can be damaged if subjected to more than 1/2

psig (3.48 kPa).

MANUAL MAIN

SHUT−OFF VALVE

WILL NOT HOLD

NORMAL TEST

PRESSURE

CAP

ISOLATE

GAS

VALVES

FURNACE

FIGURE 14