Lochinvar RPV-I&S User Manual

Page 7

7

RPV-I&S

NOTE: For installations requiring both horizontal and vertical runs,

the following rule must be followed: Total number of feet of straight

pipe (both horizontally and vertically) must not exceed the allowable

length listed in the “Through The Wall” section of the table for total

number of elbows used. Also: Total number of vertical feet of straight

pipe must not exceed the allowable length listed in the “Through The

Roof” section of the table for total number of elbows used. For

angular rises in venting, any angle that is greater than or equal to

45° from the horizontal should be considered a vertical rise.

HIGH ALTITUDE INSTALLATIONS FOR ELEVATIONS OVER 2,000 FEET

(610 m) ABOVE SEA LEVEL

The capacity of the induced draft blower declines with increasing altitude due to

a reduction in the air density. In order to assure safe and reliable performance

of the water heater, the following guidelines must be followed. Refer to the

venting tables below for maximum distances for the altitudes in your location.

COMBUSTION AIR SUPPLY

Provide adequate air for combustion and ventilation. An insufficient supply of

air will cause recirculation of combustion products resulting in air contamination

that may be hazardous to life. Such a condition often will result in a yellow,

luminous burner flame, causing carbon build up or sooting of the combustion

chamber, burners, and flue tubes with possible damage to the heater.

When an exhaust fan is installed in the same room with a heater, sufficient

openings for air must be provided in the walls. Undersized openings will cause

air to be drawn into the room through the chimney, causing recirculation of

combustion products.

Unconfined Spaces

In unconfined spaces in buildings, infiltration may be adequate to provide air

for combustion, ventilation, and dilution of flue gases. However, in buildings of

tight construction (for example, weather stripping, heavily insulated, caulked,

vapor barrier, etc.), additional air may need to be provided using the methods

described under CONFINED SPACES: All Air From Outdoors or Specially Engineered

Installations.

Confined Spaces

Confined spaces are spaces defined as having less than 50 ft.

3

/1000 BTU

(1.4 m

3

/0.29 kw-hr).

All Air From Inside the Building: The confined space must be provided

with two permanent openings communicating directly with an additional room(s)

of sufficient volume so that the combined volume of all spaces meets the

criteria for an unconfined space. The total input of all gas utilization equipment

installed in the combined space must be considered in making this determination.

Each opening must have a minimum free area of 1 square inch per 1000 BTU

(6.5 cm

2

/0.29 kw) per hour of the total input rating of all gas utilization

equipment in the confined space, but not less than 100 square inches (645

cm

2

). One opening must be within 12 inches (31 cm) of the top and one within

12 inches (31 cm) of the bottom of the enclosure.

All Air From Outdoors: The confined space must be provided with two

permanent openings, one commencing within 12 inches (31 cm) of the top and

one commencing within 12 inches (31 cm) from the bottom of the enclosure.

The openings must communicate directly, or by ducts, with the outdoors or

spaces (crawl or attic) that freely communicate with the outdoors.

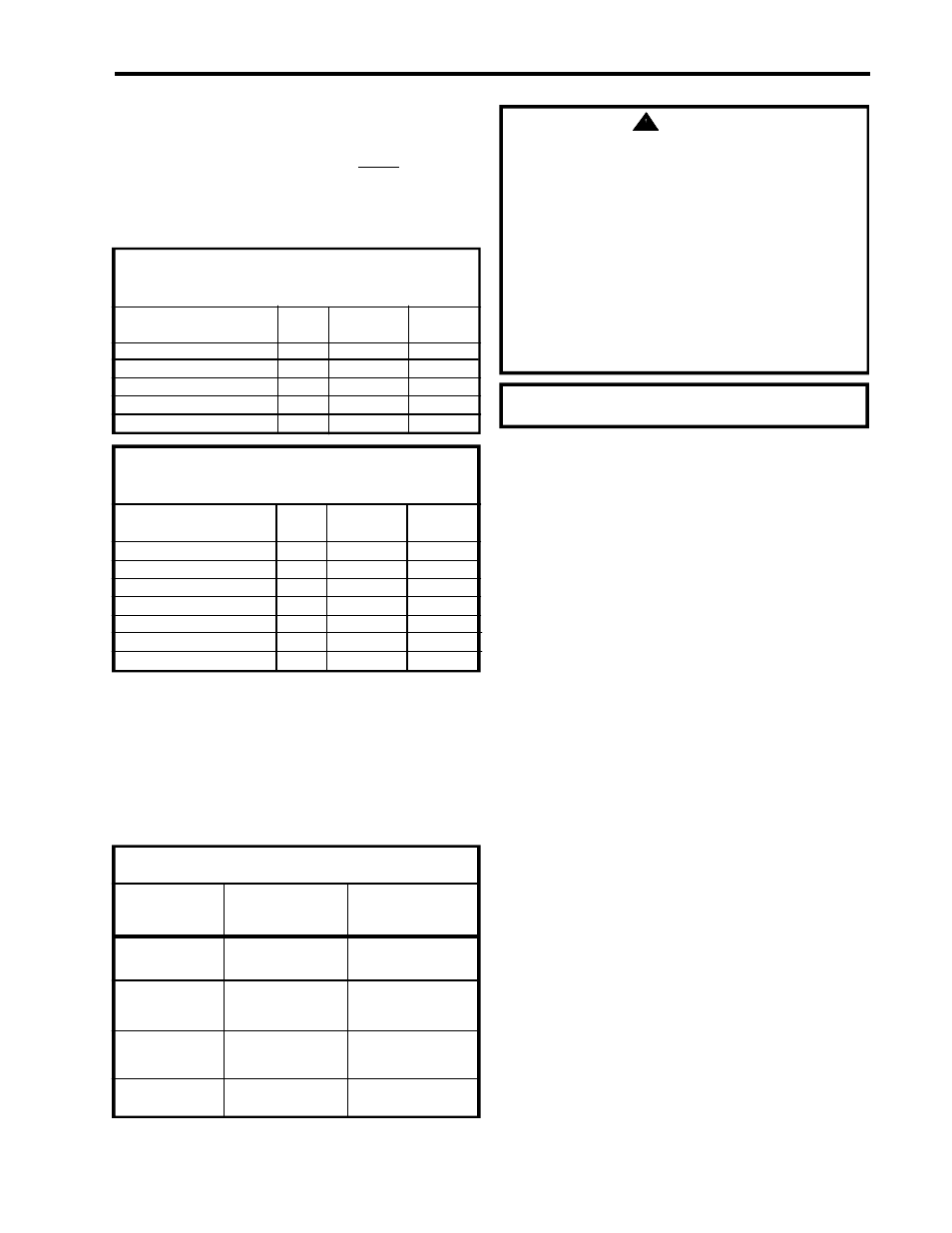

TABLE - 9

2" (5.1 cm) PVC VENT CONNECTOR LENGTHS FROM INSIDE WALL

FOR LOW GROUND CLEARANCE INSTALLATIONS

Terminating

# of Maximum Minimum

Elbows Length Length

(2) 90° Elbows with Vent Terminal

0

35 ft (10.7 m)

2 ft (.6 m)

(2) 90° Elbows with Vent Terminal

1

30 ft (9.2 m)

2 ft (.6 m)

(2) 90° Elbows with Vent Terminal

2

25 ft (7.6 m)

2 ft (.6 m)

(2) 90° Elbows with Vent Terminal

3

20 ft (6.1 m)

3 ft (.9 m)

(2) 90° Elbows with Vent Terminal

4

15 ft (4.6 m)

4 ft (1.2 m)

TABLE - 10

3" (7.6 cm) VENT CONNECTOR LENGTHS FROM INSIDE WALL

FOR LOW GROUND CLEARANCE INSTALLATIONS

Terminating (Reduce 3" to 2") # of Maximum Minimum

(Reduce 7.6 cm to 5.1 cm)

Elbows Length Length

(2) 90° Elbows with (1) 90° Elbow

1

60 ft (18.3 m)

10 ft (3 m)

(2) 90° Elbows with Vent Terminal

0

90 ft (27.5 m)

10 ft (3.1 m)

(2) 90° Elbows with Vent Terminal

1

85 ft (25.9 m)

10 ft (3.1 m)

(2) 90° Elbows with Vent Terminal

2

80 ft (24.4 m)

10 ft (3.1 m)

(2) 90° Elbows with Vent Terminal

3

75 ft (22.9 m)

10 ft (3.1 m)

(2) 90° Elbows with Vent Terminal

4

70 ft (21.4 m)

10 ft (3.1 m)

(2) 90° Elbows with Vent Terminal

5

65 ft (19.8 m)

12 ft (3.7 m)

WARNING

Liquefied petroleum gases/propane gas are heavier than air and will remain

at floor level if there is a leak. Basements, crawl spaces, closets and areas

below ground level will serve as pockets for accumulation of leaking gas.

Before lighting, smell all around the appliance area for gas. Be sure to smell

next to the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any telephone

in your building.

• Immediately call your gas supplier from a neighbor’s

telephone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

DO NOT OPERATE APPLIANCE UNTIL LEAKAGE IS CORRECTED!

IMPORTANT

The flow of combustion and ventilating air must not be obstructed.

TABLE - 11

HIGH ALTITUDE VENT CONNECTOR MODIFICATIONS

Altitude above

Maximum venting

Maximum venting

sea level

length reduction

length reduction

tables 7 & 9

tables 8 & 10

Reduce maximum vent

length by 20 ft (6.1 m)

No reduction in vent

length required

over 2,000 - 5,000ft

(over 610 - 1524 m)

0 - 2,000 ft

(0 - 610 m)

No reduction in vent

length required

over 5,000 - 8,000 ft

(over 1524 - 2439 m)

Use only 3" (7.6 cm)

PVC (Tables 8 & 10)

No reduction in vent

length required

over 8,000 - 10,000 ft

(over 2439 - 2540 m)

Use only 3" (7.6 cm)

PVC (Tables 8 & 10)

Reduce maximum vent

length by 20 ft (6.1 m)

No reduction in vent

length required