Lochinvar RPV-I&S User Manual

Page 3

3

RPV-I&S

76,000 BTU (283.9 L - 22.3 kW/Hr) models. Part II will cover

venting specifications for 40 Gal - 40,000 BTU (151.4 L - 11.7 kW/

Hr) and 48 gal - 40,000 BTU (181.7 L - 11.7 kW/Hr) models. Refer

to the rating plate located on the water heater for correct model

identification.

The National Fuel Gas Code ANSI Z223.1-(Latest Edition), CGA/CAN B149

Installation Code, and local codes have specific requirements for the location

of the vent terminals on vertical walls. The guide lines listed below are from

the National Fuel Gas Code. Consult the local codes, and/or National Fuel Gas

Code ANSI Z223.1-(Latest Edition), or CGA/CAN B149 Installation Code to

determine if there are any additions or changes to the following specifications.

(A) The vent terminal must terminate at least 3 feet (.91 m) above any

forced air inlet duct located within 10 feet (3 m). Exception: This

provision shall not apply to the combustion air intake of a direct vent

appliance.

(B) The vent terminal must terminate at least 4 feet (1.2m) below, 4 feet

(1.2 m) horizontally from, or 1 foot (0.31 m) above any door, window,

gravity air inlet into the building.

(C) The bottom of the vent terminal must be located at least 1 foot

(0.31 m) above ground and above the anticipated snow level.

(D) The vent terminal must not terminate over a public walkway or over an

area where condensate or vapor could create a nuisance or hazard

or could be detrimental to the operation of regulators, relief valve, or

other equipment.

(E) The water heater location must provide easy access for the entire

length of the vent connector.

(F) The vent system must be inspected at least once a year to ensure

against leakage of exhaust products.

Exceptions For Installations in Canada:

(A) The vent terminal must be located at least 1 foot (0.31 m) from any

window or door which can be opened in any building, any non-mechanical

air supply inlet to any building, or the combustion air to any inlet other

appliance.

(B) The vent terminal must be located at least 6 feet (1.8 m) from any

mechanical air supply inlet to the building.

(C) The vent terminal must not terminate above a meter/regulator

assembly within 3 feet (0.91 m) horizontally of the vertical center line

of the regulator and must be at least 6 feet (1.8 m) from any gas

service regulator vent outlet.

(D) The vent terminal must be at least 7 feet (2.1 m) above a paved

sidewalk or a paved driveway located on public property.

(E) The vent terminal must not terminate above a paved sidewalk or a

paved driveway, which is located on private adjacent property.

VENTING SYSTEM CONDENSATION

Condensate formation does not occur in all installations of power vented

heaters, but should be protected against on installations where condensation

can form in the venting system.

Formation of condensation in the venting system of Power Vented water

heaters is dependent upon installation conditions including, but not limited to:

1. Ambient temperature and humidity of installation location;

2. Ambient temperature and humidity of venting space; vent distance and

slope;

3. And product usage.

In order to effectively control condensate from adversely affecting the

mechanical components of the water heater several methods may be employed:

1. For horizontal installations the vent pipe can be installed with a downward

slope (not less than 1/8" nor greater than 1/2” per foot maximum) and

away from the blower motor.

2. In order to prevent condensate from draining back into the blower (vertical

or horizontal runs), a fitting and drain hose is available as a condensate

trap kit (see Table 1 for service part numbers). The all rubber fitting with

drain outlet mounts directly to the blower motor outlet and is secured with

two hose clamps (one to the blower motor outlet and the other to the vent

connector). The plastic tubing is provided to drain any accumulated

condensate away from the water heater and to a suitable drain. The kit

comes complete with instructions for proper installation of the fitting.

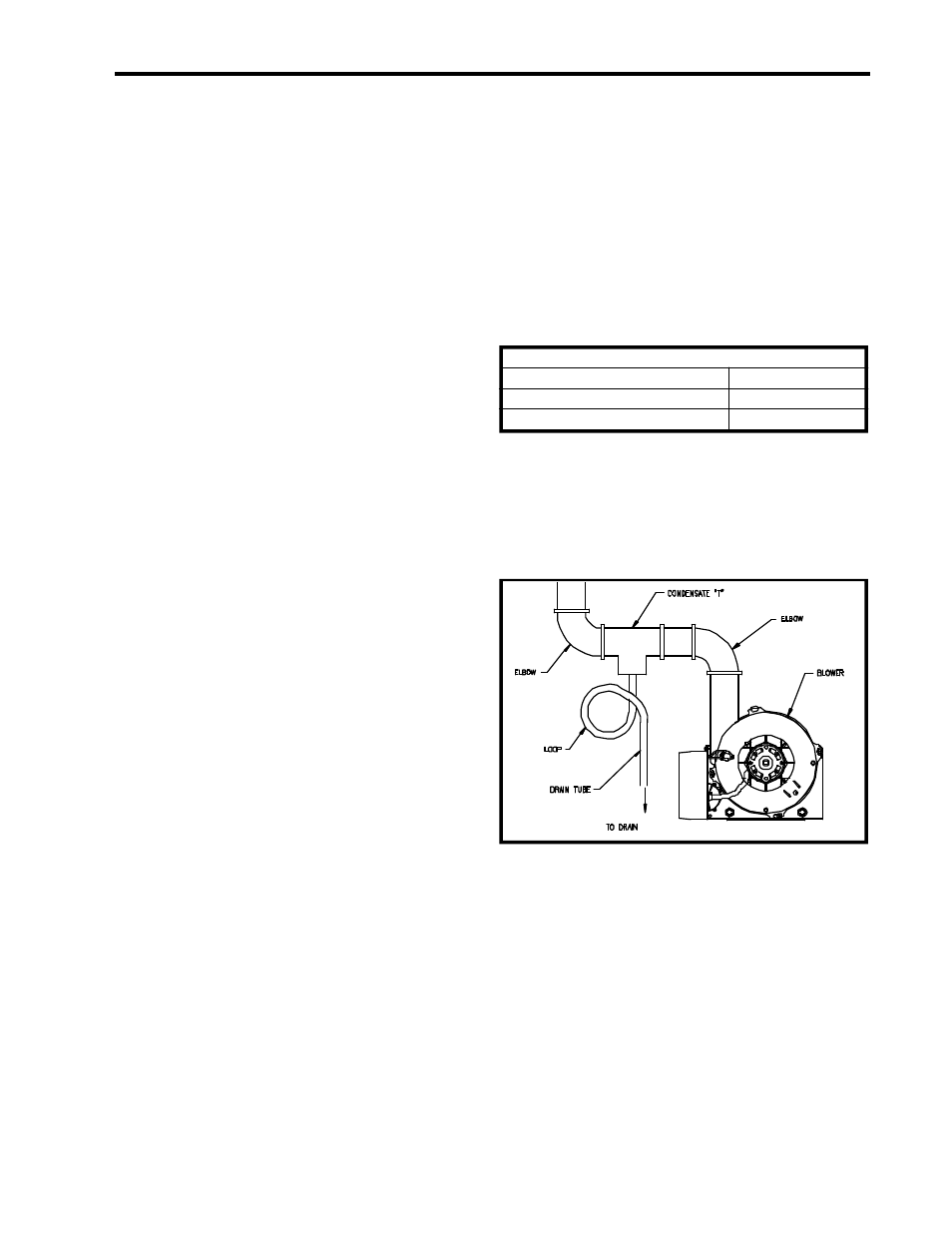

3. In order to prevent condensate from draining back into the blower (vertical

or horizontal runs), a drain tee and condensate trap can be installed in the

horizontal vent as close as practical to the blower vent connection (see

Figure1). The condensate disposal tube should be installed to drain any

accumulated condensate away from the water heater and to a suitable

drain. The drain tee and condensate hose should be available through

your local distributor.

Part I - Venting Specifications for:

48 Gallon, 65,000 BTU input (181.7 L, 19.1 kW/Hr)

65 Gallon, 65,000 BTU input (246.1 L, 19.1 kW/Hr)

75 Gallon, 76,000 BTU input (283.9 L, 22.3 kW/Hr)

This water heater is a power vented appliance and is designed to vent its

products of combustion through 3" (7.6 cm) or 4" (10.2 cm) diameter Schedule

40 (solid or cellular core) PVC pipe to the outdoors. This water heater may be

either vented through the wall or vertically through the roof. Use a 3" (7.6 cm)

to 4" (10.2 cm) reducer to connect to the vent outlet when using 4" (10.2 cm)

PVC. Table 2 lists the maximum vent lengths for this water heater using 3" (7.6

cm) PVC. If possible, locate the water heater so that the venting length and

number of elbows are kept to the minimum distance necessary to reach the

outside. If the installation requires venting lengths that exceed the lengths

listed for 3" (7.6 cm) PVC in Table 2, then use 4" (10.2 cm) PVC for the vent

connector. Table 3 lists the venting distances allowed with 4" (10.2 cm)

Table - 1

Model Service Part

2" (5.1 cm) Blower Outlet (exhaust)

DRV1200

3" (7.6 cm) Blower Outlet (exhaust)

DRV1201

Figure 1