Operation, Warning, Caution – Lincoln Electric LN -15 WIRE FEEDER IM823-A User Manual

Page 22

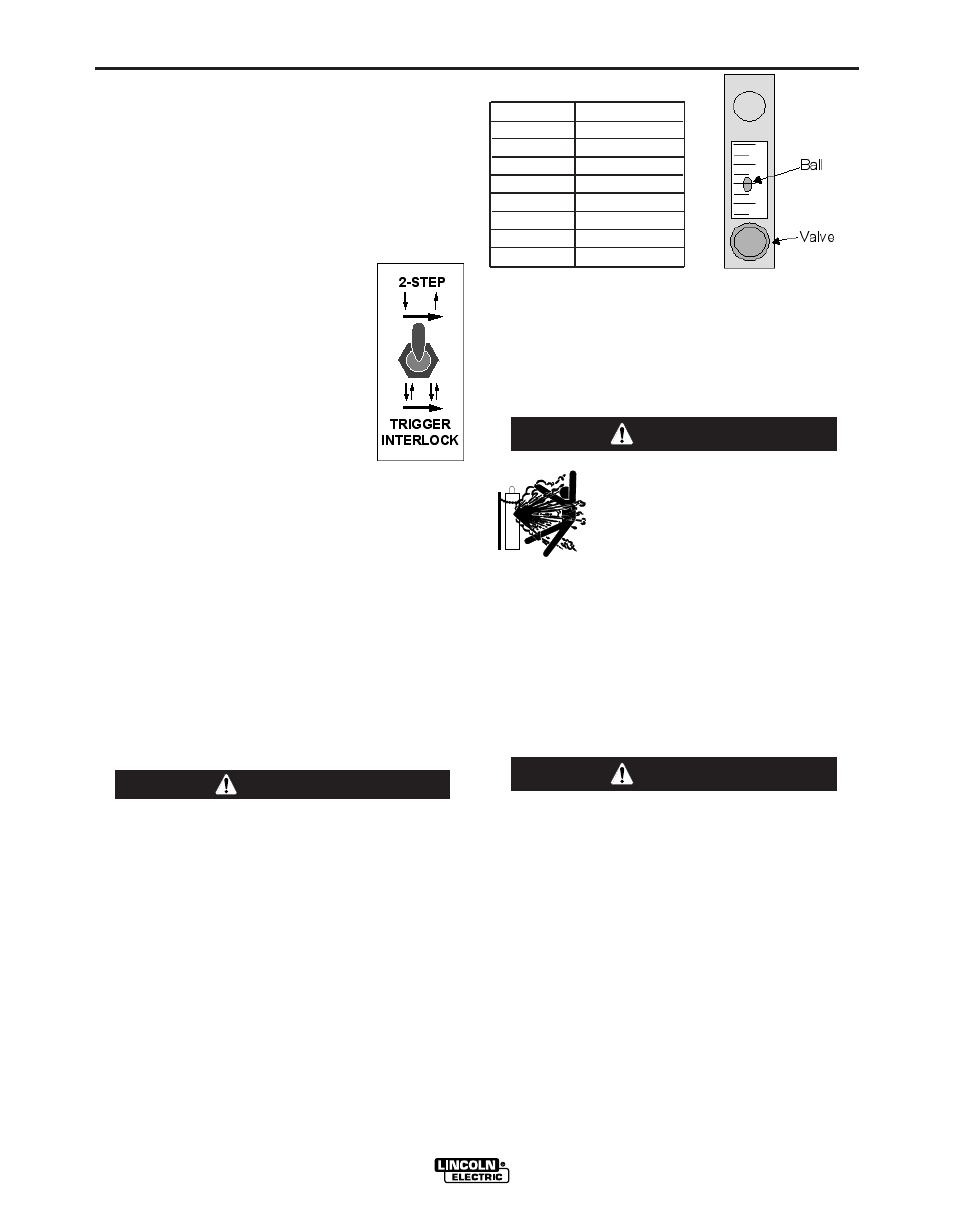

SCFH

Liter/Min.

10

4.7

20

9.4

30

14.2

40

18.9

50

23.6

60

28.3

70

33.1

80

37.8

SPINDLE BRAKE

Adjust the spindle brake tension to allow the spool to

spin freely, yet have enough resistance for little or no

overrun when wire feeding is stopped.

SHIELDING GAS CONNECTION

CYLINDER may explode if

damaged.

• Keep cylinder upright and

chained to support.

• Keep cylinder away from areas where it may be

damaged.

• Never lift welder with cylinder attached.

• Never allow welding electrode to touch cylinder.

• Keep cylinder away from welding or other live

electrical circuits.

-----------------------------------------------------------------------

• B U I L D U P O F S H I E L D I N G G A S M A Y H A R M

HEALTH OR KILL.

• Shut off shielding gas supply when not in use.

• See American National Standard Z-49.1, "Safety

i n W e l d i n g a n d C u t t i n g ” P u b l i s h e d b y t h e

American Welding Society.

-----------------------------------------------------------------

Customer must provide a cylinder of shielding gas,

a pressure regulator, a flow control valve and a hose

from the flow valve to the gas inlet fitting of the

LN™-15.

Connect a supply hose from the gas cylinder flow

valve outlet to the 5/8-18 female inert gas fitting on the

back of the LN™-15.

WARNING

WARNING

B-7

OPERATION

B-7

LN™-15 ACROSS THE ARC MODEL & (CE)

Hold with toggle switch in the DOWN position to acti-

vate Gas Purge and let the shielding gas flow. The

gas solenoid valve will energize but neither the power

source output nor the drive motor will be turned on.

The Gas Purge switch is useful for setting the proper

flow rate of shielding gas. Flow meters should always

be adjusted while the shielding gas is flowing.

2 STEP - TRIGGER INTERLOCK SWITCH

The 2 Step - Trigger Interlock switch

changes the function of the gun trigger.

2 Step trigger operation turns welding on

and off in direct response to the trigger.

Trigger Interlock operation allows weld-

i n g t o c o n t i n u e w h e n t h e t r i g g e r i s

released for comfort on long welds.

Place the toggle switch in the UP posi-

tion for 2 Step operation or in the DOWN

position for Trigger Interlock operation.

2 Step Trigger

2 Step trigger operation is the most common. When

the gun trigger is pulled, the welding power source

energizes the electrode output and the wire feeder

feeds wire for welding. The power source and wire

feeder continue welding until the trigger is released.

Trigger Interlock

Trigger Interlock operation provides for operator com-

fort when making long welds. When the gun trigger is

first pulled, the welding power source energizes the

output and the wire feeder feeds wire for welding.

The gun trigger is then released while the weld is

made. To stop welding, the gun trigger is pulled again,

and when it is released the welding power source out-

put turns off and the wire feeder stops feeding wire.

If the arc goes out while welding with trigger inter-

lock operation, the electrode output from the

welding power source remains energized and the

wire feeder will continue to feed wire until the gun

trigger is again pulled and then released.

-----------------------------------------------------------------

FLOW METER

The flowmeter shows the flow rate of shielding gas

and has a valve to adjust the flow. The flow meter is

calibrated for CO2, Ar, and CO2/Ar blends. The mid-

dle of the ball indicates the flow rate of shielding gas.

Adjust the flow rate by turning the valve at the bottom

of the meter. Most weld procedures require 25-40 scfh

(11.8 - 18.9 lpm) for sufficient shielding gas coverage.

Gun angle, nozzle diameter, joint configuration and

wind conditions may effect the amount of shielding

gas required.

CAUTION