Troubleshooting, Caution – Lincoln Electric INVERTEC IM904 User Manual

Page 27

E-4

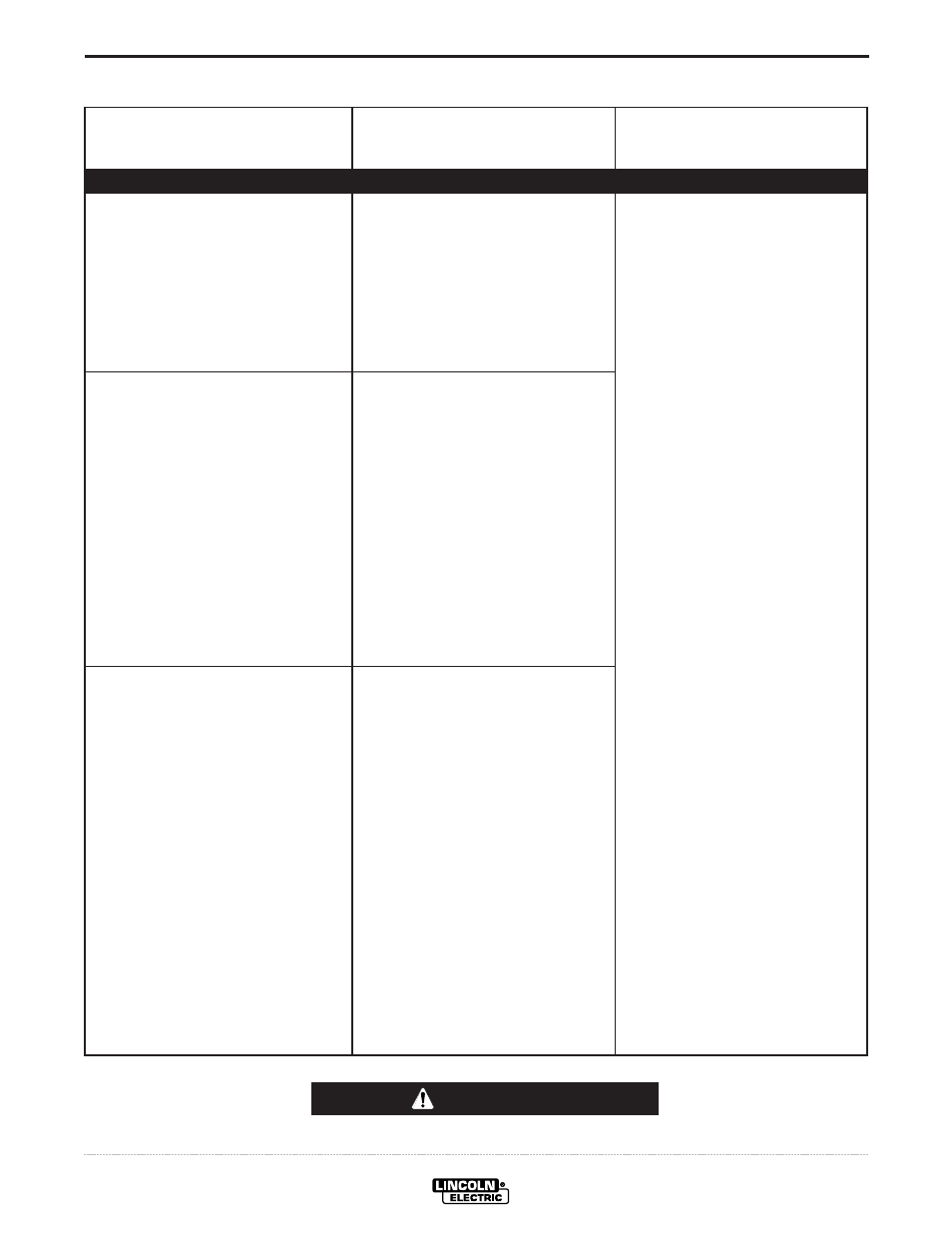

TROUBLESHOOTING

E-4

INVERTEC STT II (CE)

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

Observe Safety Guidelines detailed in the beginning of this manual.

PROBLEMS

(SYMPTOMS)

No output or reduced output the first

time power is applied to the

machine.

Machine loses output while welding.

The thermal indicator light is lit.

Normal welding output returns after

about 10 minutes.

Machine has low OCV, and loses

output while attempting to weld.

POSSIBLE

CAUSE

1. Check input voltages, fuses and

input voltage reconnect proce-

dures. See Installation section.

2. If high input voltage (380VAC or

higher) is applied, the capacitors

may need conditioning. Let the

“

unloaded

”

machine idle for 30

minutes.

1. Check to make sure the fans are

running and operating correctly.

2. Welding application may exceed

recommended duty cycle.

3. Dirt and dust may have clogged

the cooling channels. Blow out

unit with clean, dry compressed

air.

4. Air intake and exhaust louvers

may be blocked due to inade-

quate clearance around machine.

1. Check for faulty connection on

plug J1 on Control Board and

plug J1 on Current Sense Board.

2. Check for faulty Current Sense

Board.

RECOMMENDED

COURSE OF ACTION

If all recommended possible areas

of misadjustment have been

checked and the problem persists,

Contact your local Lincoln

Authorized Field Service

Facility.

OUTPUT PROBLEMS