General, Venting – Lochinvar SYNC 1.3 User Manual

Page 19

19

Requirements for installation in Canada

1. Installations must be made with a vent pipe system

certified to ULC-S636.

IPEX is an approved vent manufacturer in Canada

supplying vent material listed to ULC-S636.

2. The first three (3) feet of plastic vent pipe from the

appliance flue outlet must be readily accessible for visual

inspection.

3. The components of the certified vent system must not be

interchanged with other vent systems or unlisted

pipe/fittings. For concentric vent installations, the inner

vent tube must be replaced with field supplied certified

vent material to comply with this requirement.

2

General

venting

(continued)

Installation & Operation Manual

Installing vent and air piping

Improper installation of PVC or CPVC

systems may result in injury or death.

ƽ CAUTION

Use only cleaners, primers, and solvents

that are approved for the materials which

are joined together.

NOTICE

1. Work from the boiler to vent or air termination. Do not

exceed the lengths given in this manual for the air or vent

piping.

2. Cut pipe to the required lengths and deburr the inside

and outside of the pipe ends.

3. Chamfer outside of each pipe end to ensure even cement

distribution when joining.

4. Clean all pipe ends and fittings using a clean dry rag.

(Moisture will retard curing and dirt or grease will

prevent

adhesion.)

5. Dry fit vent or air piping to ensure proper fit up before

assembling any joint. The pipe should go a third to

two-thirds into the fitting to ensure proper sealing after

cement is applied.

6. Priming

and

Cementing:

a. Handle fittings and pipes carefully to prevent

contamination

of

surfaces.

b. Apply a liberal even coat of primer to the fitting

socket.

c. Apply a liberal even coat of primer to the pipe end to

approximately 1/2" beyond the socket depth.

d. Apply a second primer coat to the fitting socket.

e. While primer is still wet, apply an even coat of

approved cement to the pipe equal to the depth of

the

fitting

socket.

f. While primer is still wet, apply an even coat of

approved cement to the fitting socket.

g. Apply a second coat of cement to the pipe.

h. While the cement is still wet, insert the pipe into the

fitting, if possible twist the pipe a 1/4 turn as you insert

it.

NOTE: If voids are present, sufficient cement was

not applied and joint could be defective.

i. Wipe excess cement from the joint removing ring or

beads as it will needlessly soften the pipe.

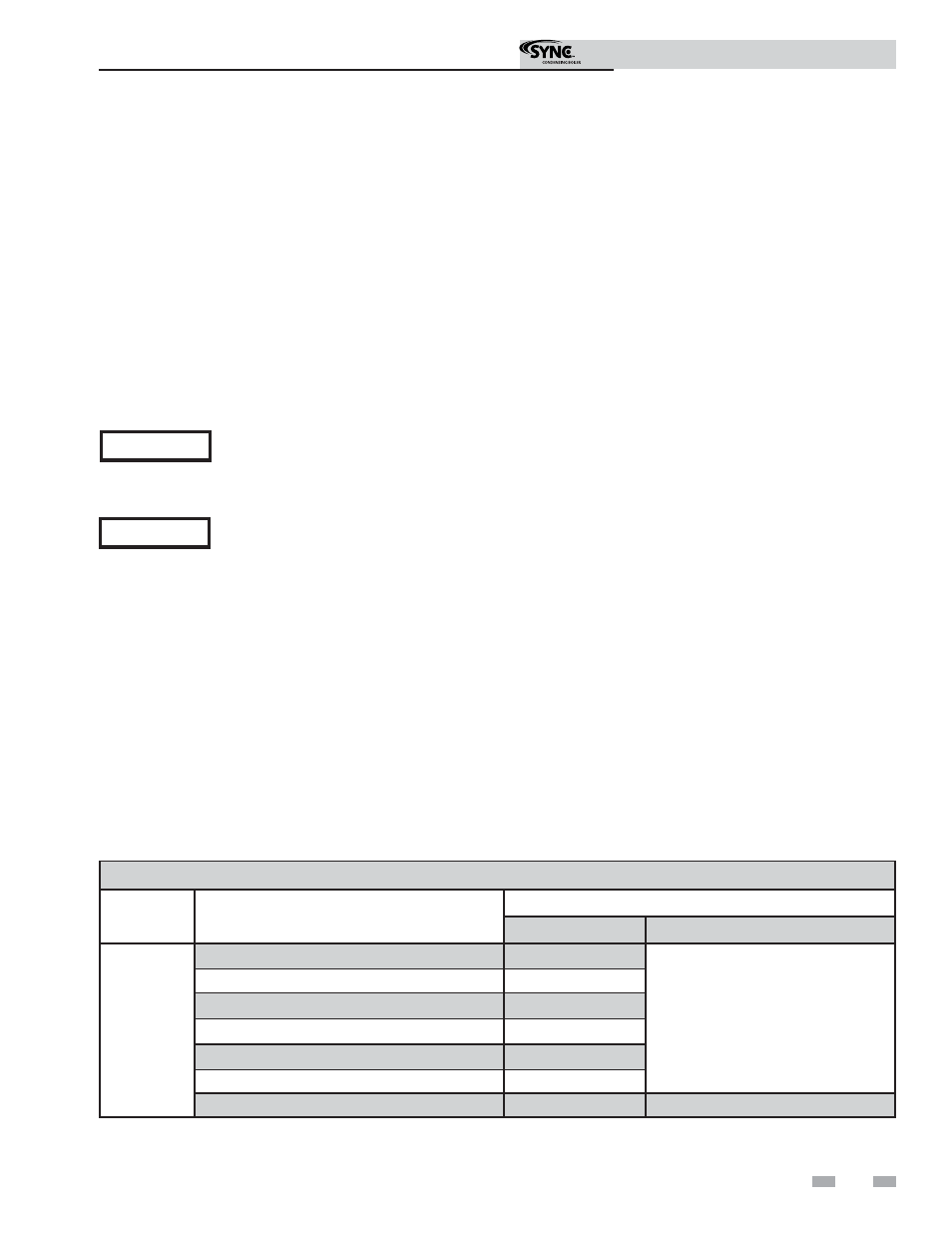

Table 2A PVC, Vent Pipe, and Fittings

All vent pipe materials and fittings must comply with the following:

Item

Material

Standards for installation in:

United States

Canada

Vent pipe

and fittings

PVC Plastic Pipe, Schedules 40, 80, & 120 ANSI/ASTM D1785

CPVC and PVC venting must be

ULC-S636 Certified. IPEX is an

approved manufacturer in Canada

supplying vent material listed to

ULC-S636.

PVC Plastic Pipe Fittings, Schedule 40

ANSI/ASTM D2466

PVC Plastic Pipe Fittings, Schedule 80

ANSI/ASTM D2467

PVC - DWV Pipe and Fittings

ANSI/ASTM D2665

CPVC Plastic Pipe, Schedule 40 & 80

ANSI/ASTM F441

CPVC Plastic Pipe Fittings, Schedule 80

ANSI/ASTM F439

AL29-4C

UL1738

ULC-S636