Operation, General description, Recommended processes and equipment – Lincoln Electric POWER WAVE 455TM IM583-A User Manual

Page 15: Design features and advantages, Additional design features and advantages

B-3

OPERATION

B-3

POWER WAVE 455

GENERAL DESCRIPTION

The Power Wave 455 is a high performance, digitally

controlled inverter welding power source capable of

complex, high-speed waveform control. Properly

equipped, it can support the GMAW, GMAW-P,

FCAW, SMAW, GTAW and CAC-A processes.

RECOMMENDED PROCESSES AND

EQUIPMENT

RECOMMENDED PROCESSES

The Power Wave can be set up in a number of config-

urations, some requiring optional equipment. Each

machine is factory preprogrammed with multiple weld-

ing procedures, typically including GMAW, GMAW-P,

FCAW, SMAW, GTAW and CAC-A, for a variety of

materials, including mild steel, stainless steel, cored

wires, and aluminum.

RECOMMENDED EQUIPMENT

The Power Wave 455 must be used with the Power

Feed family of wire feeders. These feeders are

required to access and make use of the many of the

welding features contained in the Power Wave 455.

DESIGN FEATURES AND ADVANTAGES

A unique feature of the Power Wave is the ability to

function without any controls, when used with Power

Feed wire feeders. All power source control informa-

tion comes to the Power Wave from a Power Feed

wire feeder.

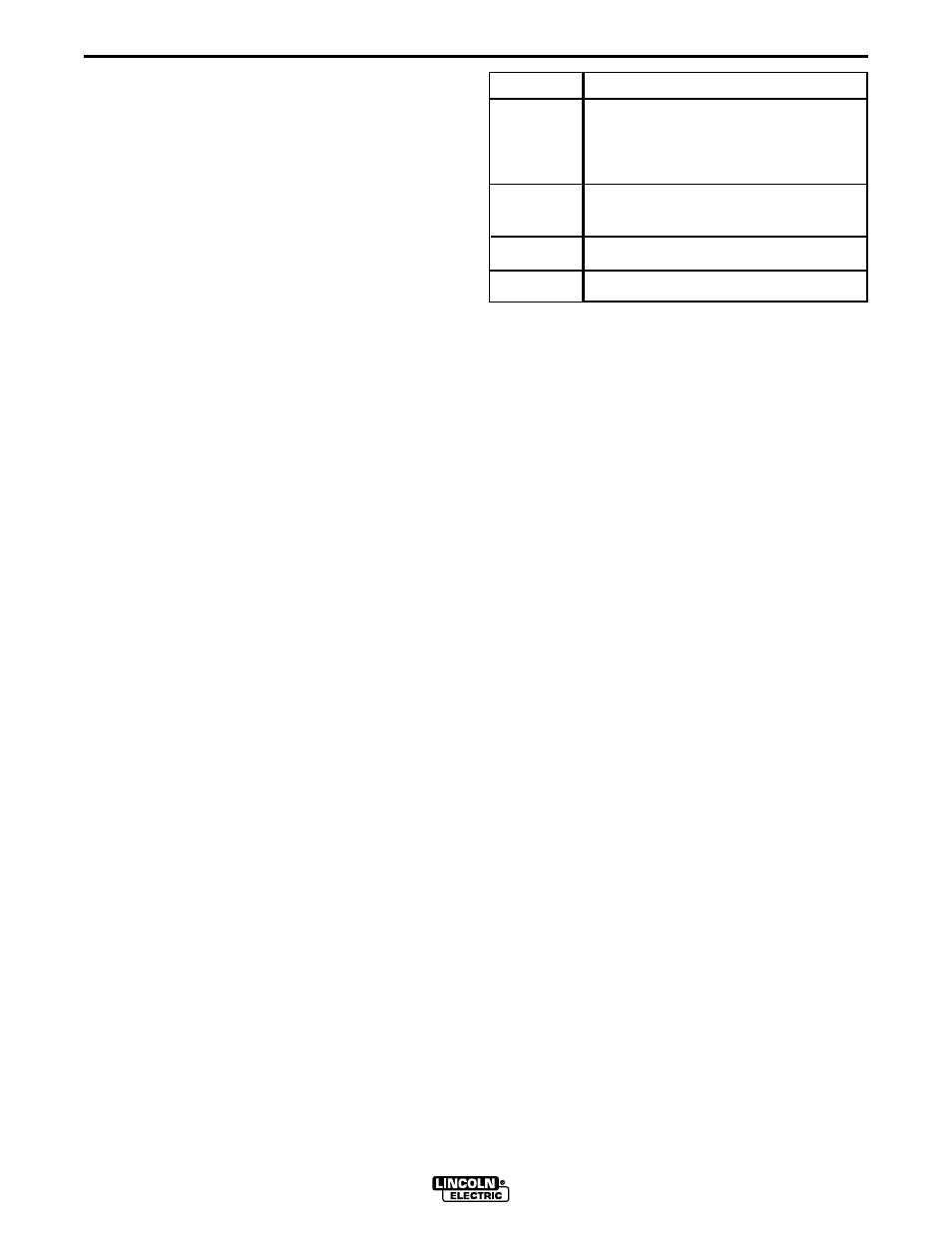

The following chart lists the power source parameters

that can be changed from the Power Feed wire feed-

er, and gives examples of each. (Optional equipment

may be required to access some of the following para-

meters.)

ADDITIONAL DESIGN FEATURES AND

ADVANTAGES

• Designed to NEMA EW-1, IEC 974-1 and CSA

Standards.

• Qualifies for “S” mark on nameplate, which means it

can be used in areas where there is increased risk

of electric shock.

• Multiple process output ranges: 5 - 570 amps.

• Easy access for input connections. Connections

are simple strip and clamp (no lugs required).

• F.A.N. (fan as needed). (On codes above 10500

only) Cooling fan runs only when necessary.

• Modular construction for easy servicing.

• Thermostatically protected.

• Electronic over current protection.

• Input over voltage protection.

• Utilizes digital signal processing and microprocessor

control.

• Simple, reliable input voltage change over.

• All system components communicate and transfer

information.

• Auto device recognition simplifies accessory cable

connections.

Parameter

Welding

Mode

Output

Trim

Arc Control

Examples

Stick Crisp, Stick Soft, Flux Cored with Gas,

Flux Cored without Gas, CV, Synergic CV,

.035 Stainless Pulse, .045 Steel Pulse, 5356

Aluminum Pulse

Current (CC modes), Voltage (CV modes),

Wire Feed Speed (synergic modes)

.500 to 1.500 (only in Pulse modes)

-10.0 to +10.0