Hydronic piping – Lochinvar Knight XL 399 - 800 User Manual

Page 38

Installation & Operation Manual

38

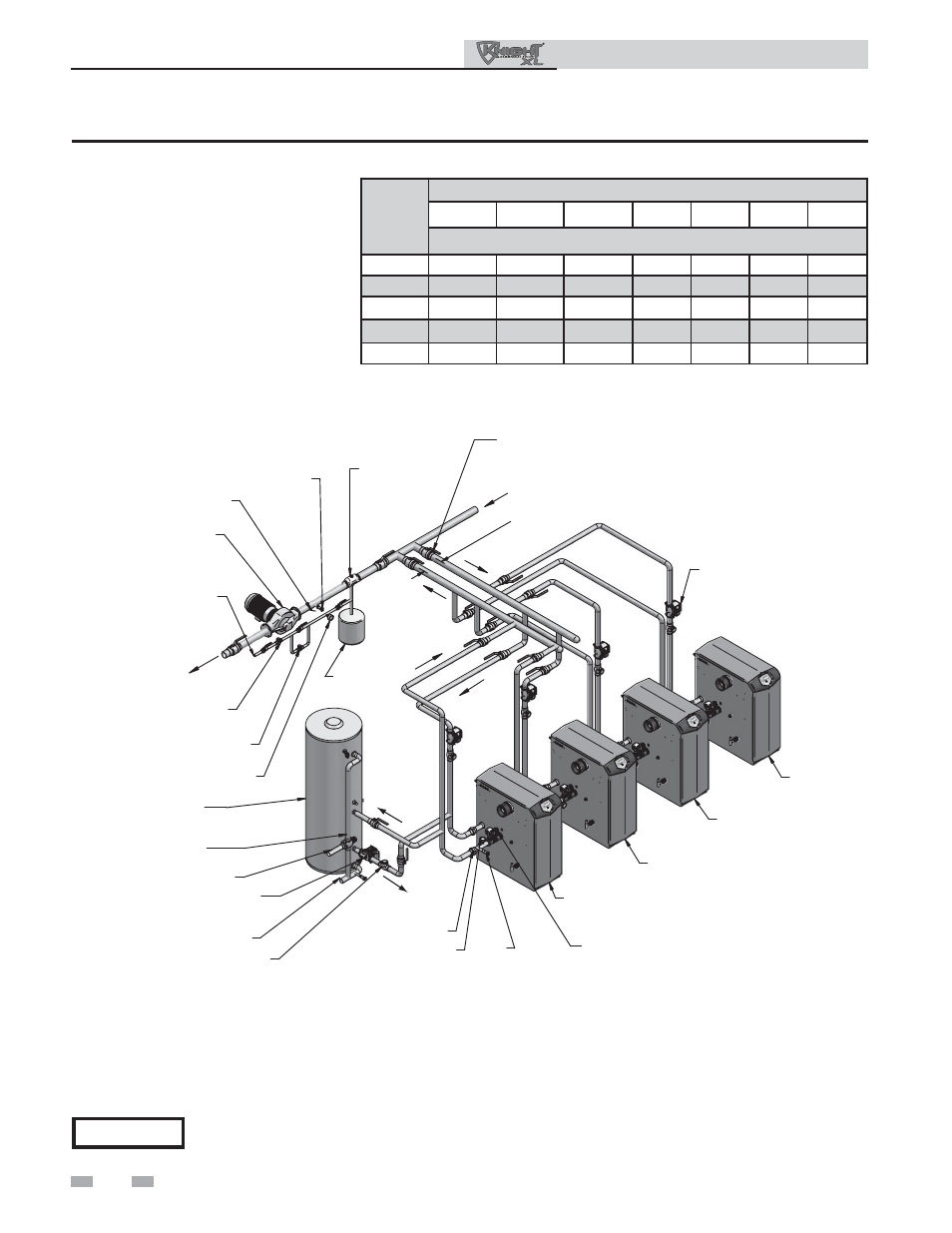

EXPANSION

TANK

AIR SEPARATOR

PRESSURE REDUCING

VALVE

BACK FLOW

PREVENTER

BALL VALVE

(TYPICAL)

UNION (TYPICAL)

PRESSURE RELIEF VALVE

FLOW CHECK

VALVE (TYPICAL)

INDIRECT DHW

TANK

BOILER 1

(LEADER)

TEMPERATURE /

PRESSURE GAUGE

PRESSURE GAUGE

DRAIN

DRAIN POINT

(TYPICAL)

BOILER CIRCULATOR

(TYPICAL)

ANTI-SCALD

MIXING VALVE

SYSTEM SUPPLY SENSOR

SYSTEM CIRCULATOR

TO

SYSTEM

FROM SYSTEM

BOILER 2

(MEMBER 1)

BOILER 3

(MEMBER 2)

BOILER 4

(MEMBER 3)

DOMESTIC

HOT WATER

CIRCULATOR

COLD WATER IN

HOT WATER OUT

MAKE UP WATER

NO

T T

O E

XC

EED

4 PIPE DIAMETERS

OR

A MAXIMUM OF 12”

AP

AR

T

Figure 6-8 Multiple Boilers - Primary/Secondary Piping

Model

Number of Units

2

3

4

5

6

7

8

Manifold Pipe Sizes in Inches (mm)

399

2 1/2 (64)

3 (76)

3 1/2 (89) 4 (102) 4 (102) 5 (127) 6 (152)

500

3 (76)

3 1/2 (89) 4 (102)

5 (127) 5 (127) 6 (152) 6 (152)

600

3 1/2 (89) 4 (102)

5 (127)

5 (127) 6 (152) 6 (152) 8 (203)

700

3 1/2 (89) 5 (127)

5 (127)

6 (152) 6 (152) 8 (203) 8 (203)

800

4 (102)

5 (127)

5 (127)

6 (152) 8 (203) 8 (203) 8 (203)

NOTICE

System flow should always remain higher than the required flow for the boiler(s) when the boiler(s) is in operation to

prevent short cycling and high limit issues.

6

Hydronic piping