Hydronic piping, Installation & operation manual – Lochinvar Knight XL 399 - 800 User Manual

Page 37

Installation & Operation Manual

37

6

Hydronic piping

(continued)

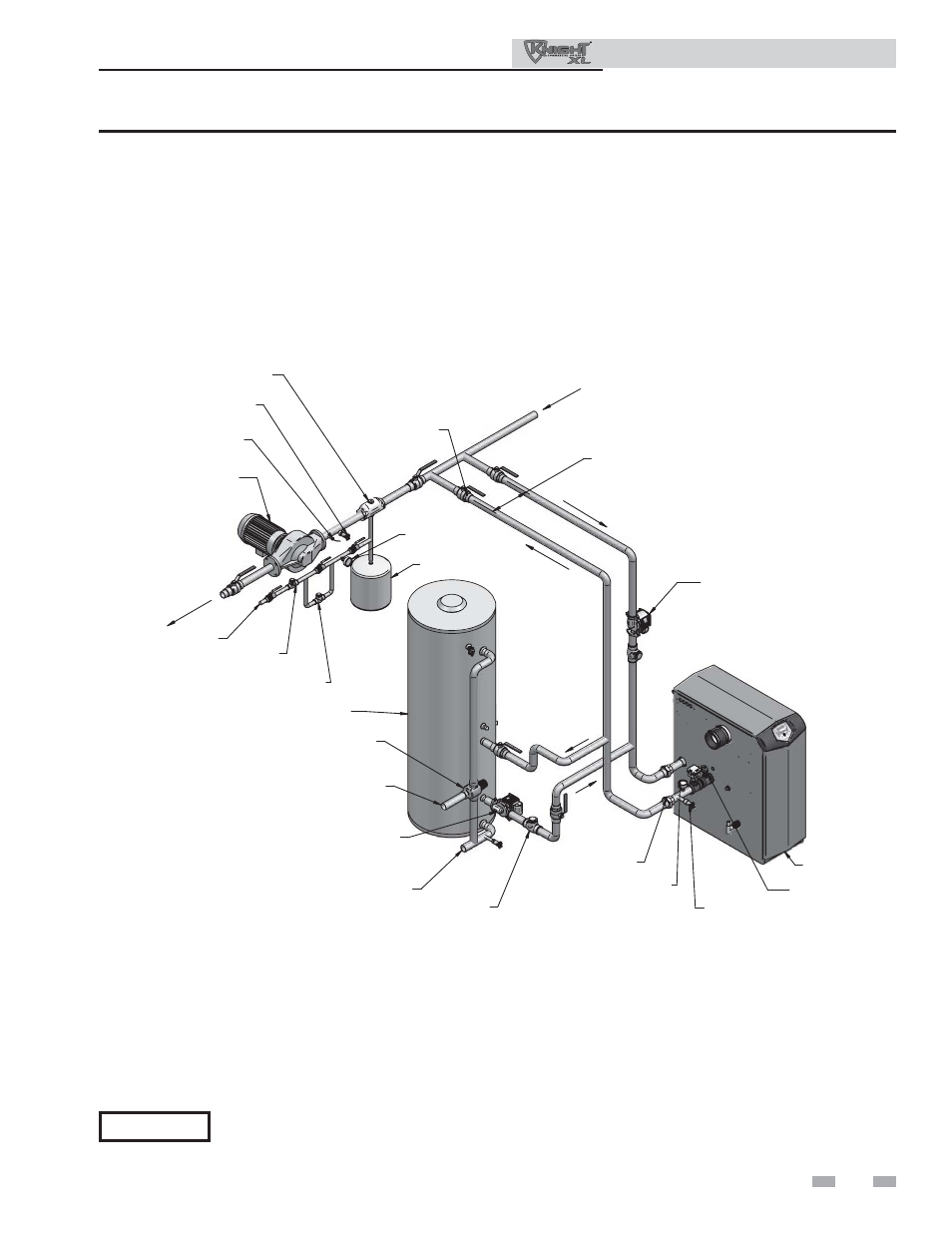

EXPANSION TANK

AIR SEPARATOR

PRESSURE REDUCING

VALVE

BACK FLOW

PREVENTER

BALL VALVE

(TYPICAL)

UNION (TYPICAL)

PRESSURE RELIEF

VALVE

FLOW CHECK

VALVE (TYPICAL)

INDIRECT DHW

TANK

BOILER

TEMPERATURE / PRESSURE

GAUGE

PRESSURE GAUGE

DRAIN

DRAIN POINT

(TYPICAL)

BOILER CIRCULATOR

COLD WATER IN

ANTI-SCALD

MIXING VALVE

SYSTEM SUPPLY SENSOR

SYSTEM CIRCULATOR

TO

SYSTEM

FROM SYSTEM

DOMESTIC

HOT WATER

CIRCULATOR

HOT WATER OUT

MAKE UP WATER

NOT TO EXCEED 4 PIPE DIAMETERS OR

A MAXIMUM OF 12” APART

Figure 6-7 Single Boiler - Primary/Secondary Piping

NOTICE

System flow should always remain higher than the required flow for the boiler(s) when the boiler(s) is in operation to

prevent short cycling and high limit issues.

See also other documents in the category Lochinvar Water boiler:

- KNIGHT XL KBN800 (6 pages)

- SD (2 pages)

- Copper Fin II CF-1261 (1 page)

- EBS-SUB-02 (2 pages)

- Commercial Water Heater (2 pages)

- 999 - 750 (72 pages)

- JR-SUB-07 (2 pages)

- POWER-FIN PB/PF 2001 (4 pages)

- Squire SSS041 (20 pages)

- Knight Heating Boiler 81-286 (48 pages)

- 1302 (2 pages)

- CH/CF/CP 300-750 (4 pages)

- 000 (80 pages)

- Copper-fin CW-360 (1 page)

- CP-5M-4/08 (52 pages)

- 500 (68 pages)

- 000 - 260 (52 pages)

- 000 - 260 (52 pages)

- TNR-I&S-02 (20 pages)

- ARMOR 150 - 800 (36 pages)

- KNIGHT KB-500 (1 page)

- PB 502 thru 1302 (4 pages)

- PB-1302(M9) (1 page)

- MDN 030 (2 pages)

- 495 (52 pages)

- Hot Water Generator (24 pages)

- Heating Boilers KB 400 thru 801 (4 pages)

- SYNO 1.3 (16 pages)

- SQUIRE SIT119 (24 pages)

- Commercial Gas Glass Lined Tanke Type Water Heater CG200 (28 pages)

- COPPER-FIN CB-0745 (1 page)

- 0402-0752 (2 pages)

- 1.3 (56 pages)

- RPV-I&S (16 pages)

- KNIGHT 400 (48 pages)

- KNIGHT 210 (20 pages)

- Power Fin PF-0502 (M9) (2 pages)

- COPPER-FIN II 402 - 2072 (16 pages)

- 752 (16 pages)

- WATER HEATERS (12 pages)

- EFFICIENCY+ E B N 150 (2 pages)

- Sync Condensing Boiler 1.5 (56 pages)

- EB 150 -- 300 (4 pages)

- CW495-2066 (2 pages)

- CREST 2.5 (60 pages)