Kawasaki 840641 User Manual

Page 11

19

T

TR

RO

OU

UB

BL

LE

ES

SH

HO

OO

OT

TIIN

NG

G C

CH

HA

AR

RT

T –

– W

WE

EL

LD

DE

ER

R

S

SY

YM

MP

PT

TO

OM

M

P

PO

OS

SS

SIIB

BL

LE

E C

CA

AU

US

SE

ES

S((S

S))

C

CO

OR

RR

RE

EC

CT

TIIV

VE

E A

AC

CT

TIIO

ON

N

20

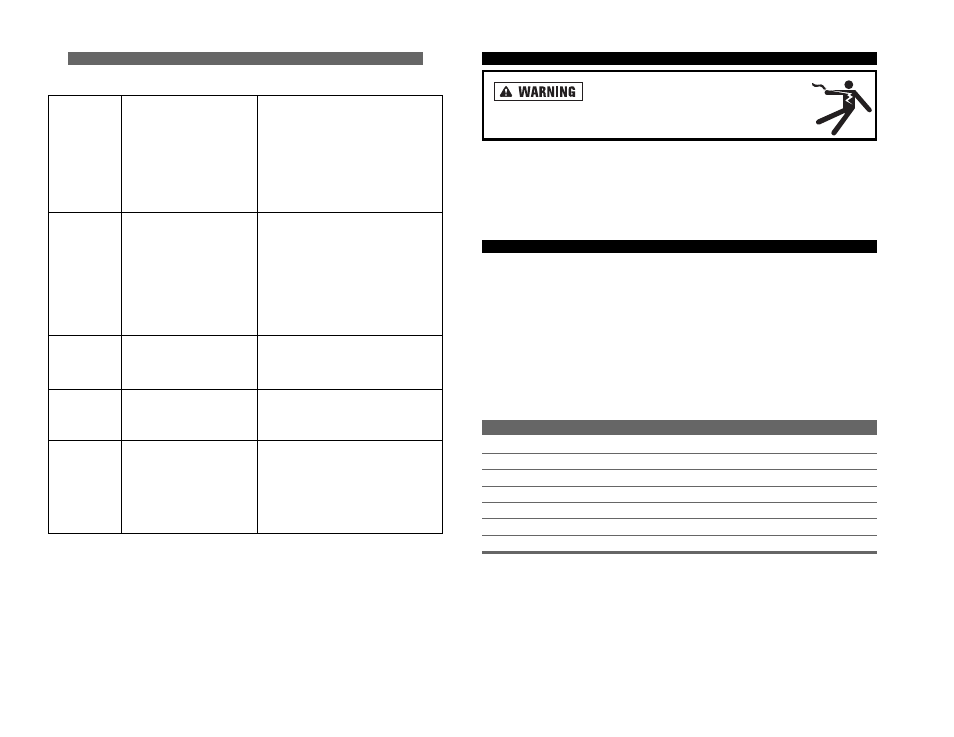

No Output

1. Duty cycle exceeded

2. Poor work clamp

connection

3. Defective ON/OFF switch

4. Tripper circuit breaker or

blown fuse

1. Allow welder to cool down until

ON/OFF Switch lamp goes out

2. Be sure all connections are secure

and attaching surface is clean

3. Replace switch

4. Reduce circuit load, reset breaker

or replace fuse

Wire tangles

at drive roller

1. Wrong size gun tip

2. Gun liner clogged or

damaged

3. Gun tip clogged or

damaged

4. Feed roller worn

5. Not enough tension

1. Use proper size gun tip

2. Clean or replace gun liner

3. Clean or replace gun tip

4. Replace feed roller

5. Tighten tensioning screw

Gun nozzle

arcs to work

piece

1. Slag inside gun nozzle

1. Clean slag from gun nozzle

Work clamp

and/or cable

gets hot

1. Poor contact

1. Ensure all connections are secure

and attaching surface is clean

Wire does

not feed

1. Wire jammed

2. Out of wire

3. Not enough tension

4. Wire liner worn

1. Reload wire

2. Replace wire spool

3. Tighten tensioning screws if wire

is slipping

4. Replace liner

M

MA

AIIN

NT

TE

EN

NA

AN

NC

CE

E A

AN

ND

D C

CL

LE

EA

AN

NIIN

NG

G

A

Allw

waayyss U

UN

NP

PL

LU

UG

G tth

hee A

Arrcc W

Weelld

deerr ffrro

om

m tth

hee A

AC

C

p

po

ow

weerr sso

ou

urrccee b

beeffo

orree cclleeaan

niin

ng

g o

orr m

maaiin

ntteen

naan

nccee..

• K

Keeeep

p tth

hee A

Arrcc W

Weelld

deerr cclleeaan

n aan

nd

d d

du

usstt ffrreeee.. Never use water to clean the Arc

Welder. Always use compressed air to blow out dust.

• D

DO

O N

NO

OT

T aatttteem

mp

ptt tto

o rreep

paaiirr tth

hee A

Arrcc W

Weelld

deerr yyo

ou

urrsseellff.. If the unit is not working

properly, DO NOT use it until it has been repaired and inspected by a qualified

technician.

A

AC

CC

CE

ES

SS

SO

OR

RIIE

ES

S

U

Ussee o

on

nllyy aacccceesssso

orriieess tth

haatt aarree rreecco

om

mm

meen

nd

deed

d b

byy tth

hee m

maan

nu

uffaaccttu

urreerr ffo

orr yyo

ou

urr m

mo

od

deell..

Accessories that may be suitable for one tool may become hazardous when used on

another tool.

A

Allw

waayyss aattttaacch

h g

grro

ou

un

nd

deed

d ((3

3--p

prro

on

ng

g)) eexxtteen

nssiio

on

n cco

orrd

dss tto

o g

grro

ou

un

nd

deed

d ((3

3--h

ho

ollee)) o

ou

uttlleettss..

IIff yyo

ou

u m

mu

usstt u

ussee aan

n eexxtteen

nssiio

on

n cco

orrd

d,, b

bee ssu

urree tth

haatt tth

hee g

gaau

ug

gee iiss llaarrg

gee een

no

ou

ug

gh

h tto

o ccaarrrryy

tth

hee aam

mo

ou

un

ntt o

off ccu

urrrreen

ntt n

neecceessssaarryy ffo

orr yyo

ou

urr p

po

ow

weerr tto

oo

oll.. If not, your tool may experi-

ence a loss of power, excessive voltage drop or overheating. The smaller the gauge

number, the heavier the cord (see table below).

R

RE

EC

CO

OM

MM

ME

EN

ND

DE

ED

D S

SIIZ

ZE

ES

S O

OFF E

EX

XT

TE

EN

NS

SIIO

ON

N C

CO

OR

RD

DS

S 1

12

20

0 V

VO

OL

LT

T A

AC

C 6

60

0 H

HZ

Z T

TO

OO

OL

LS

S

T

TO

OO

OL

L C

CU

UR

RR

RE

EN

NT

T R

RA

AT

TIIN

NG

G

C

CO

ON

ND

DU

UC

CT

TO

OR

R S

SIIZ

ZE

E IIN

N A

A..W

W..G

G

AMPERE

10FT.

25FT.

50FT.

100FT.

3-6

18

18

18

18

6-8

18

18

18

16

8-10

18

18

18

14

10-12

16

16

14

14

12-16

14

12

12

-

16-20

12

12

12

-