Kawasaki 840641 User Manual

Page 10

17

W

WE

EL

LD

DIIN

NG

G P

PO

OS

SIIT

TIIO

ON

NS

S

Welding positions can be categorized into four basic types: flat, horizontal, vertical,

and overhead. Welding in the flat position is the easiest of all the different types

because welding speed can be increased and the molten metal has a less tendency

to run, better penetration can be achieved and the work is less fatiguing. Welding is

performed with wire at a 45° travel angle and a 45° work angle. Other positions

require different welding techniques such as weaving pass, circular pass, or jogging

pass. These techniques should only be attempted as the welder’s skills improve over

time. Overhead welding is least desirable position as it is the most dangerous and

most difficult. Heat setting and wire selections are more critical in this type. The

same special requirements are true for horizontal and vertical welding. For specific

applications, consult an arc welding technical manual.

A

AD

DD

DIIT

TIIO

ON

NA

AL

L S

SA

AFFE

ET

TY

Y S

ST

TA

AN

ND

DA

AR

RD

DS

S

• A

AN

NS

SII S

Sttaan

nd

daarrd

d Z

Z4

49

9..1

1:: From the American Welding Society.

• S

Saaffeettyy aan

nd

d H

Heeaalltth

h S

Sttaan

nd

daarrd

dss:: OSHA 29 CFR 1910.

• N

Naattiio

on

naall E

Elleeccttrriiccaall C

Co

od

dee:: NPFA Standards 51B and 70 from the National fire

Protection Association.

• C

Co

od

dee FFo

orr S

Saaffeettyy iin

n W

Weelld

diin

ng

g aan

nd

d C

Cu

uttttiin

ng

g:: CSA Standard W117.2, from

Canadian Standards Association.

• S

Saaffee P

Prraaccttiicceess ffo

orr O

Occccu

up

paattiio

on

naall aan

nd

d E

Ed

du

uccaattiio

on

naall E

Eyyee aan

nd

d FFaaccee P

Prro

otteeccttiio

on

n::

ANSI Standard Z87.1 from American National Standards Institute.

T

TR

RO

OU

UB

BL

LE

ES

SH

HO

OO

OT

TIIN

NG

G C

CH

HA

AR

RT

T –

– W

WE

EL

LD

DS

S

S

SY

YM

MP

PT

TO

OM

M

P

PO

OS

SS

SIIB

BL

LE

E C

CA

AU

US

SE

ES

S((S

S))

C

CO

OR

RR

RE

EC

CT

TIIV

VE

E A

AC

CT

TIIO

ON

N

T

TR

RO

OU

UB

BL

LE

ES

SH

HO

OO

OT

TIIN

NG

G C

CH

HA

AR

RT

T –

– W

WE

EL

LD

DS

S

S

SY

YM

MP

PT

TO

OM

M

P

PO

OS

SS

SIIB

BL

LE

E C

CA

AU

US

SE

ES

S((S

S))

C

CO

OR

RR

RE

EC

CT

TIIV

VE

E A

AC

CT

TIIO

ON

N

B

BE

EL

LO

OW

W A

AR

RE

E S

SE

EV

VE

ER

RA

AL

L D

DIIFFFFE

ER

RE

EN

NT

T T

TY

YP

PE

ES

S O

OFF W

WE

EL

LD

D A

AP

PP

PE

EA

AR

RA

AN

NC

CE

ES

S..

Ragged

depressions

at edge of

weld

1. Travel Speed too fast

2. Wire speed too fast

3. Output heat setting too high

1. Decrease travel speed

2. Decrease wire speed

3. Reduce output heat setting

Weld bead

does not

penetrate

base metal

1. Inconsistent ravel speed

2. Output heat setting too low

3. Extension cord too long

1. Decrease and maintain constant

travel speed

2. Increase output heat setting

3. Use an extension cord no longer

than 20 feet

Wire

sputters

and sticks

1. Damp wire

2. Wire speed too fast

3. Wrong type of wire

1. Use dry wire and store in dry place

2. Reduce wire speed

3. Use FLUX CORE wire only - do not

use MIG or copper color wire

Bead is

intermittently

too thin

1. Inconsistent travel

speed

2. Output heat setting too low

1. Decrease and maintain constant

travel speed

2. Increase output heat setting

Bead is

intermittently

too thick

1. Slow and/or inconsistent

travel speed

2. Output heat setting too high

1. Increase and maintain travel

speed

2. Reduce output heat setting

N

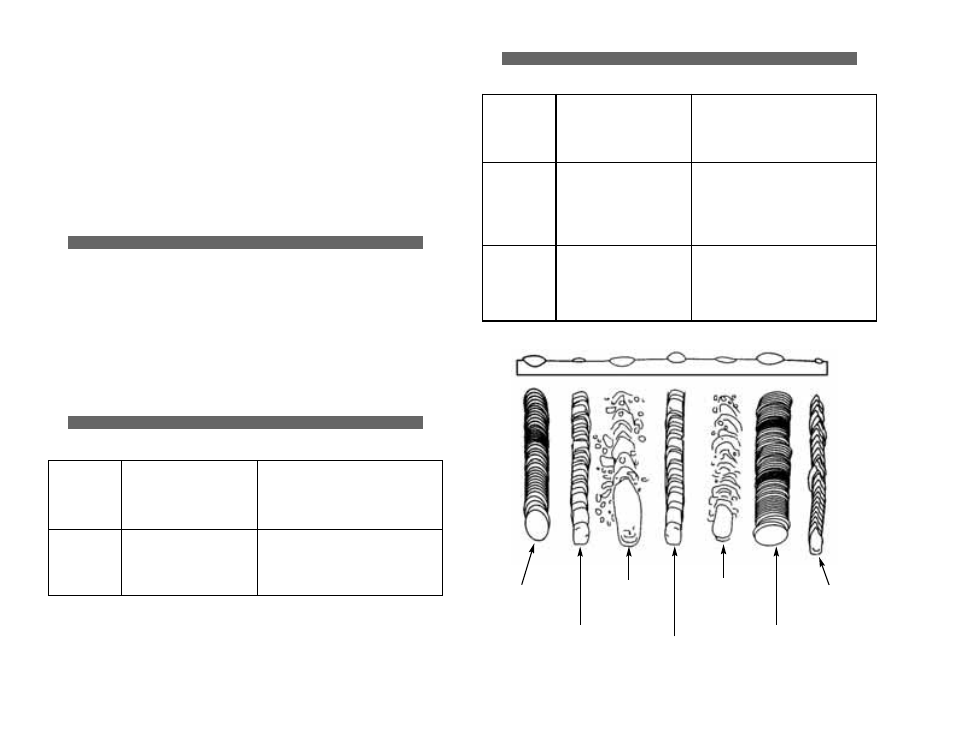

No

orrm

maall h

heeaatt,,

w

wiirree ssp

peeeed

d,,

ttrraavveell ssp

peeeed

d

HEAT TOO

LOW

HEAT TOO

HIGH

WIRE SPEED

TOO FAST

WIRE SPEED

TOO SLOW

TRAVEL SPEED

TOO SLOW

TRAVEL SPEED

TOO FAST

18