Obtaining the chemicals, Safe handling of photographic chemicals, Preparing fresh working tank solutions – Kodak FC1 User Manual

Page 2

2

Using the KODAK Negative Film Processing Cartridges FC1 and FC2

• CIS-254

OBTAINING THE CHEMICALS

Catalog numbers are as follows:

Product

Min/Mult

Order Qty

CAT Number

KODAK Negative Film

Processing Cartridge

FC1

2 801

7519

KODAK Negative Film

Processing Cartridge

FC2

2 867

2701

KODAK Rinse Tablets*

4

191 3110

KODAK Negative Film

FC Tank Developer

1 833

9723

KODAK Negative Film

FC Tank Bleach

1 107

2024

KODAK Negative Film

FC Tank Fixer

1 813

4421

KODAK Negative Film

FC Tank Rinse

3 872

4791

*Used in water reservoir on processor

SAFE HANDLING OF PHOTOGRAPHIC

CHEMICALS

Handle all chemicals carefully. When you mix solutions,

wear goggles or a face shield, a protective rubber apron,

and protective gloves made with neoprene or nitrile

rubber. Clean protective clothing after use to remove any

chemical residue that can cause contamination. For more

information about potential health hazards and safe

handling of specific Kodak chemicals, see the label and

the Material Safety Data Sheet (MSDS) for the chemical.

Consult the MSDS for regional contact information.

MSDS copies are available at the Kodak website at

www.kodak.com/go/photochemicals.

CONVERTING TO THE KODAK

NEGATIVE FILM PROCESSING

CARTRIDGES

No processor adjustments are required to use KODAK

Negative Film Processing Cartridges FC1 and FC2. These

cartridges are designed to mix and replenish on top of

existing solution. Use the same processor settings that you

use with your current chemical cartridge. Standard

conditions are shown in Figure 1 on page 3.

Preparing Fresh Working Tank Solutions

Use the following Kodak chemicals to prepare fresh

working tank solutions:

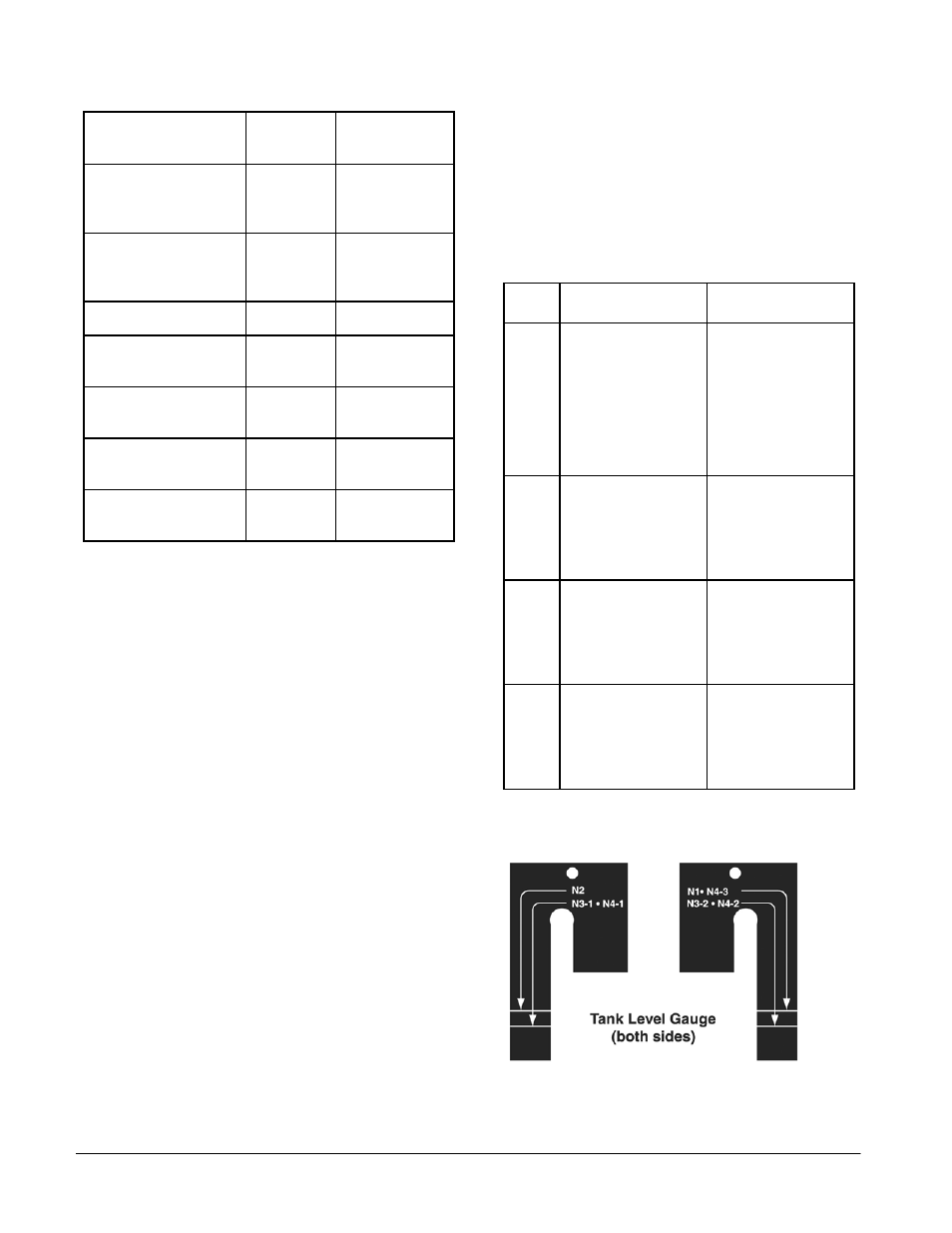

Developer Tank (N1)

Use KODAK Negative Film FC Tank Developer

CAT No. 833 9723. Each kit makes 5.2 litres. Two kits

are required for the FP363SC processor. Three kits are

required for the FP563SC processor

.

Follow the directions

in the following table:

Step

FP363SC

Processor

FP563SC

Processor

1

Mix 2 bottles of

developer Part A

with 2 litres of water

in mixing bottle. Add

solution to processor

developer (N1) tank.

Add 4 litres of water

to processor

developer (N1) tank.

Then mix 3 bottles of

developer Part A

with 2 litres of water

in mixing bottle. Add

solution to processor

developer (N1) tank.

2

Mix 2 bottles of

developer Part B

with 2 litres of water

in mixing bottle. Add

solution to processor

developer (N1) tank.

Mix 3 bottles of

developer Part B

with 2 litres of water

in mixing bottle. Add

processor developer

(N1) tank.

3

Mix 2 bottles of

developer Part C

with 2 litres of water

in mixing bottle. Add

processor developer

(N1) tank.

Mix 3 bottles of

developer Part C

with 2 litres of water

in mixing bottle. Add

processor developer

(N1) tank.

4

Position tank level

gauge on processor

developer (N1) rack.

Add water to N1

level mark (about

2.3 litres).

Position tank level

gauge on processor

developer (N1) rack.

Add water to N1

level mark (about

2.4 litres).