Health and safety, Post-processing toning procedures, For deep tank processors – Kodak A-1671 User Manual

Page 3

A-1671 December 2001

3

The Image Permanence Institute (IPI) at the

Rochester Institute of Technology (RIT) in

Rochester, New York, extensively researched redox

blemishes in microfilms.

7

IPIs research showed

that selenium toning did not effectively stop the

spread of redox. IPI then looked at a polysulfide

solution and Kodak Brown Toner solution in place of

selenium. IPIs testing showed both solutions

stopped the migration of redox blemishes into the

roll of microfilm. As a result of brown toning, toned

microfilm has a higher resistance to the formation

of redox blemishes. The combined use of brown

toning and molecular sieves significantly enhances

film longevity even under adverse conditions.

Based on Eastman Kodak Company and IPI test

results, Kodak Brown Toner has been shown to

provide additional protection against environmental

conditions that promote redox blemishes. The

treatment is effective with freshly processed and

existing microfilm collections.

Kodak Brown Toner solution can be purchased from

Eastman Kodak Company:

Kodak Catalog Number

Packaging

140-0928

1 gallon container

Kodak Brown Toner is highly photoactive with

microfilm chemicals. It is recommended that Kodak

Brown Toner be handled in a separate area from

the handling of microfilm developer and fix.

Health and Safety

When a manufacturer has determined a product is

or contains a hazardous chemical, they are required

to provide a Material Safety Data Sheet (MSDS).

Kodak provides MSDSs with all photographic

processing chemicals, even those that are not

classified as hazardous chemicals. MSDSs are

available by calling 1-800-242-2424, extension 43.

You will need to supply Kodak catalog numbers of

the chemicals for which you need MSDSs. Material

Safety Data Sheets for the actual working solutions

and caution labels for the processor tanks are also

available by calling the same number.

When working with photochemicals, it is

recommended that MSDSs for all Kodak Products

be obtained and consulted for information

pertaining to potential hazards, safe handling

guidelines, ventilation, and personal protective

equipment. While photochemical solutions and

products may contain hazardous ingredients, if the

information contained on the product label and

within each MSDS is read, understood, and

followed, normal use and handling of these

products should not pose a health risk.

Post-Processing Toning Procedures

For Deep Tank Processors*

The deep tank processor is set to run at 90

0

F.

The transport speed is determined based on a

recommended dwell time of 60 seconds in the

brown toner solution. Depending on tank size,

the transport speed varies between processors.

Mix the Kodak Brown Toner solution at a dilution

of 1:100 (1 part brown toner solution to 100 parts

water). Brown toning in deep tank processors can

be performed either in-line (as part of the normal

microfilm developing process) or off-line (use of

a dedicated processor that brown tones microfilm

after it has been processed in a separate

processor). In an Allen F-20 Processor, for

example, in-line brown toning can be accomplished

by the following tank setup:

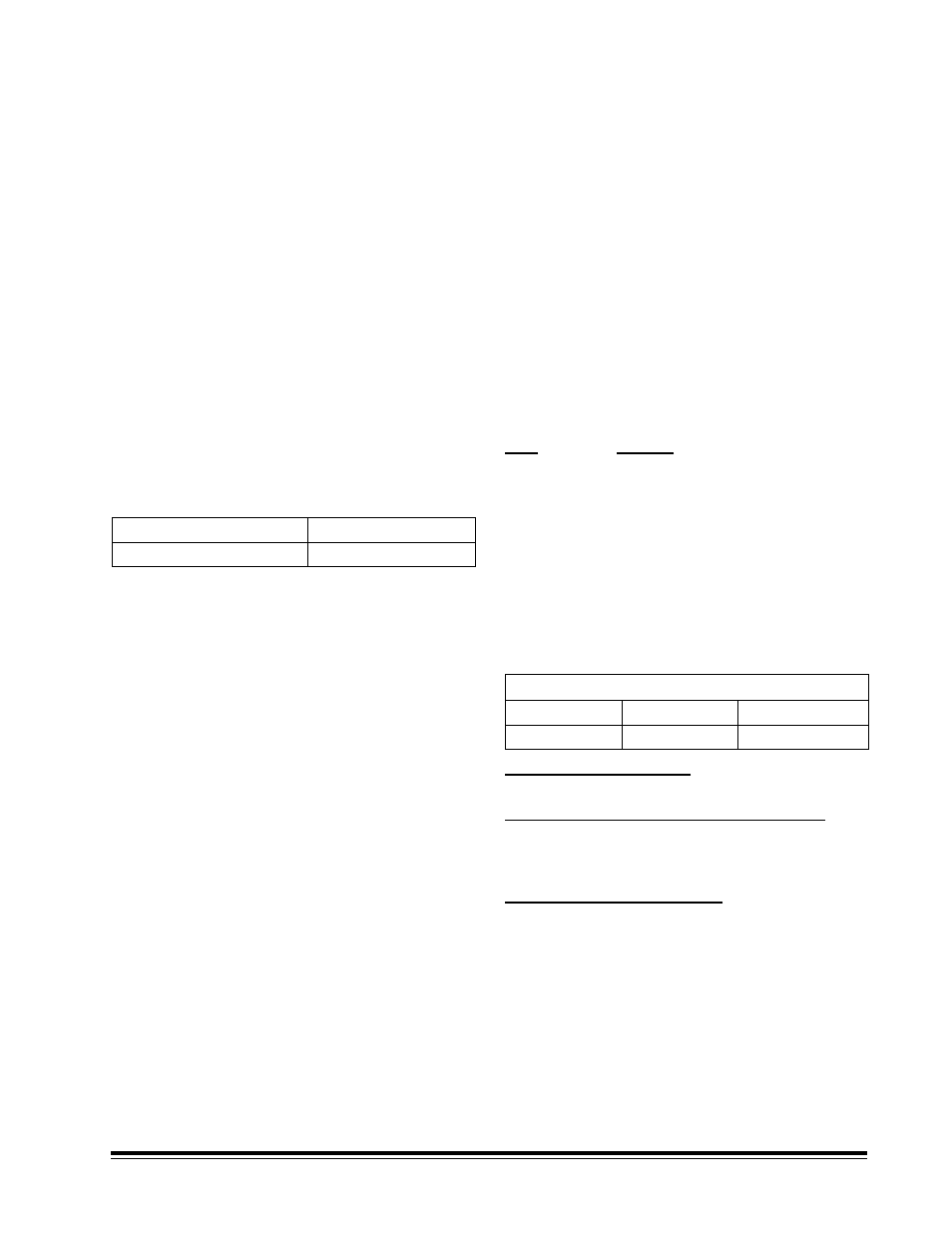

Tank

Solution

1

Developer

2

Developer

3

Wash

4

Fix

5

Fix

6

Wash

7

Brown toner solution

8

Brown toner solution

9

Wash

Calculate the replenishment rate using the following

table and formula:

Replenishment (mL/ft) by Film Width

16 mm

35 mm

105 mm

0.60

1.20

3.60

Replenishment is equal to:

Processor Transport Speed x Table Value

Sample calculation for a deep tank processor:

Film Width:

16 mm

Table Value:

0.60 mL/ft

Transport Speed:

90 ft/min

Replenishment rate is equal to:

0.60 mL/ft x 90 ft/min = 54 mL/min

Off-line brown toning in this Allen F-20 Processor

can be accomplished by filling any two consecutive

tanks with Kodak Brown Toner at the recommended

dilution rate and at a temperature of 90

0

F. A wash

tank is required immediately after the second tank

of brown toner. Set the transport speed to allow a

60 second dwell time in the brown toner solution

and calculate the replenishment rate based on the

formula described above.

*These are starting point recommendations.

Final conditions will vary.