Kawasaki 840330 User Manual

Page 7

A

AT

TT

TA

AC

CH

HIIN

NG

G W

WIIR

RE

E B

BR

RU

US

SH

HE

ES

S

Wire cup brushes, not included, can be screwed directly on the spindle. No flanges are

necessary.

E

ED

DG

GE

E G

GR

RIIN

ND

DIIN

NG

G

D

Do

o n

no

ott u

usse

e e

ed

dg

ge

e g

grriin

nd

diin

ng

g w

wh

he

ee

ellss ffo

orr ccu

utt--o

offff w

wo

orrkk,, d

de

ee

ep

p

g

grriin

nd

diin

ng

g o

orr ssu

ub

bjje

ecctt tth

he

em

m tto

o a

an

nyy ssiid

de

e p

prre

essssu

urre

e a

ass tth

hiiss m

ma

ayy lle

ea

ad

d tto

o b

brre

ea

akka

ag

ge

e

a

an

nd

d p

po

ossssiib

blle

e p

pe

errsso

on

na

all iin

njju

urryy.. These wheels should be used for shallow cutting

and notching (less than 1/2" in depth). Keep the open side of the guard away

from the operator at all times.

Edge grinding should only be done with wheels specifically designed for this purpose.

R

RE

EM

MO

OV

VIIN

NG

G G

GU

UA

AR

RD

D F

FO

OR

R S

SA

AN

ND

DIIN

NG

G O

OR

R U

US

SIIN

NG

G F

FL

LA

AT

T W

WIIR

RE

E B

BR

RU

US

SH

HE

ES

S

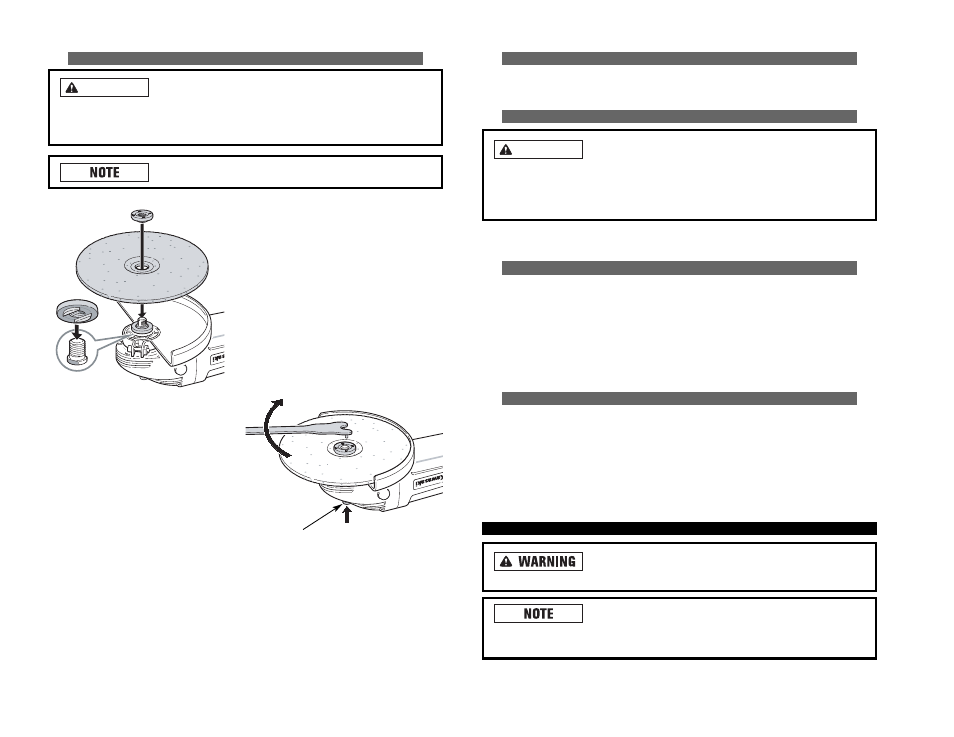

• Set the Angle Grinder on a flat surface with the spindle facing up.

• Remove the inner and outer flanges, unscrew spring washer and remove

the guard.

• Store these parts carefully.

• Replace the guard after the job is finished.

A

AT

TT

TA

AC

CH

HIIN

NG

G S

SA

AN

ND

DIIN

NG

G D

DIIS

SC

C

• To remove the guard, see instructions given in the “Removing Guard for

Sanding or Using Flat Wire Brushes” Section above.

• Set the inner flange and outer flange on the spindle.

• Push in the spindle lock button. Turn the spindle until it locks into place.

• Once the spindle is locked, tighten the sanding disc by hand.

O

OP

PE

ER

RA

AT

TIIN

NG

G T

TH

HE

E A

AN

NG

GL

LE

E G

GR

RIIN

ND

DE

ER

R

A

Allw

wa

ayyss u

un

np

pllu

ug

g tth

he

e tto

oo

oll b

be

effo

orre

e a

atttte

em

mp

pttiin

ng

g tto

o cch

ha

an

ng

ge

e tth

he

e

g

gu

ua

arrd

d o

orr a

acccce

esssso

orriie

ess..

For best tool control, material removal and minimal

loading, keep the angle between the disc and the work surface at approximate-

ly 30° when grinding and 10°-15° when sanding.

WARNING

12

A

AT

TT

TA

AC

CH

HIIN

NG

G W

WH

HE

EE

EL

LS

S W

WIIT

TH

H D

DE

EP

PR

RE

ES

SS

SE

ED

D C

CE

EN

NT

TE

ER

RS

S

A

Allw

wa

ayyss cch

he

ecckk tth

he

e tto

oo

oll w

wa

arrn

niin

ng

g lla

ab

be

ell ffo

orr tth

he

e rre

ecco

om

mm

me

en

nd

d--

e

ed

d ssp

pe

ee

ed

d rra

attiin

ng

g o

on

n a

acccce

esssso

orriie

ess.. Never run a wheel or brush over the rated

speed. Accessories exceeding the recommended speed may fly apart and cause

serious personal injury.

H

Hu

ub

bb

be

ed

d w

wh

he

ee

ellss d

do

o n

no

ott rre

eq

qu

uiirre

e m

mo

ou

un

nttiin

ng

g fflla

an

ng

ge

ess..

• When working with thick grinding

wheels, fit the threaded outer flange

with the raised area facing away

from the wheel.

• Push in the spindle lock button.

Turn the outer flange until it locks

into place.

• Once the spindle is locked, insert

the enclosed wrench into the holes

of the outer flange to tighten the

outer flange properly.

WARNING

11

SPINDLE

LOCK

BUTTON

• Check to make sure that the guard is fit-

ted properly. Put the inner flange on

the spindle.

• Put the grinding wheel on the spindle

and the inner flange.

• When working with thin grinding wheels,

fit the threaded outer flange with the

raised area facing toward the wheel.