Basic sanding, Quick tip, Operations – Woodstock SHOP FOX W1709 User Manual

Page 27

-25-

OPERATIONS

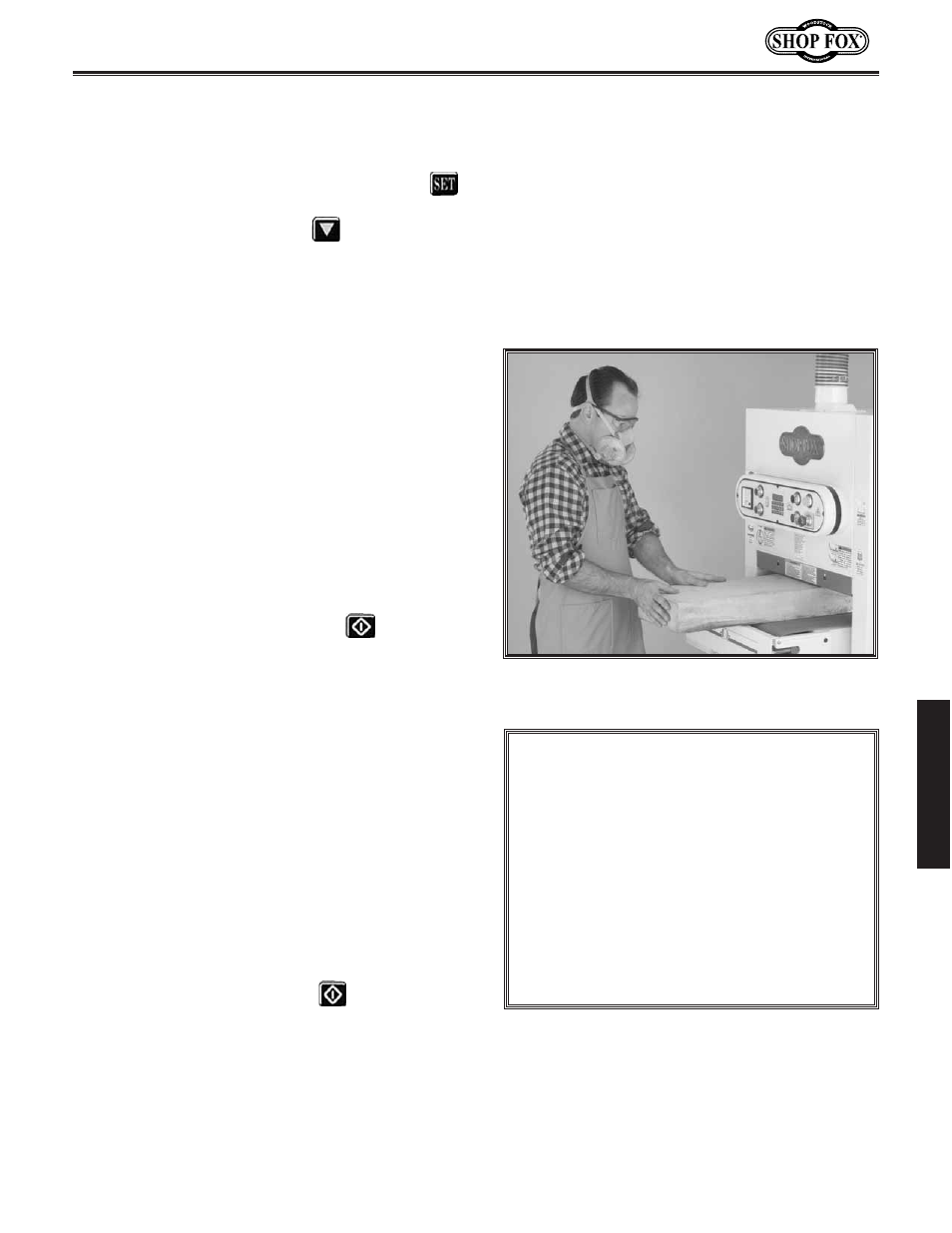

Figure 29. Operator feeding workpiece in

correct body position and out of the way of

potential kickback.

3.

Use the numeric key pad and enter the

thickness of your calibration board (Example:

1.500 for 1-

1

⁄

2

" thick).

4.

Press and hold the

SET key for 3 seconds:

The table is now calibrated.

5.

Press the down arrow key:

6.

Remove the calibration board.

To achieve the best sanding results experiment

with conveyor feed rate, sanding depth, various

grits of sandpaper, and oscillation speed.

To sand a workpiece, do these steps:

1.

Make sure the table is calibrated and the

needed sandpaper is installed and tensioned.

2.

Turn the sander

OFF, set the feed rate, then

turn the sander

ON.

3.

Measure your workpiece and find the highest

location.

4.

Type in the thickness of your workpiece

using the numeric key pad (Example: for a 2"

thick workpiece type 2.000"),

and press the table start key:

Note: the upper left corner Input Led will

illuminate (See

Figure 27), and the display

numbers will flash when entering

measurements.

5.

Measure the sanding depth needed.

Example: let’s say you need

1

⁄

16

".

Note: removing too much material can burn

the workpiece, tear the paper, and give

poor sanding results.

6.

Convert

1

⁄

16

" fraction to a 0.063" decimal

measurement using the conversion table on

the sander.

7.

Calculate the resulting workpiece thickness

(2.000"—0.063" = 1.937"), and type the

thickness (1.937") on the key pad.

8.

Press the table start key:

The table will raise 0.063".

Note: The lower left corner Run Led will

illuminate and the display numbers will glow

steady when measurements have been

accepted and the table is auto-adjusting.

Note: When the correct sanding depth is

achieved, the lower left corner Run Led will

turn off and the final resulting workpiece

thickness is displayed.

Basic Sanding

For best results for finish sanding, feed each

piece through the sander two or three times

without adjusting the depth of cut. Turn the

workpiece 180˚ and feed it through two or

three more times at this same depth. As

always, use your best judgement. If you no

longer hear the sanding belt making contact

with the workpiece on successive cuts, then

no further passes are needed at that depth.

Quick Tip

10. Start the conveyor, stand to the side as

shown in

Figure 29, and feed the

workpiece into the sander.

11. Observe the load meter, and press the

table down arrow key on the key pad to

reduce the sanding depth if there is a

problem.

12. Remove the workpiece from the outfeed

side, which is now sanded down

1

⁄

16

". You

now can add a new sanding depth the same

way as in

steps 7 and 8 and sand again.