Gas supply piping, Electrical wiring – Smith Cast Iron Boilers GS110W User Manual

Page 18

GS110 DIRECT VENT BOILER INSTALLATION AND OPERATION INSTRUCTIONS

Page 18

GAS SUPPLY PIPING

The GS110 hot water boiler comes from the factory

ready to be piped to the gas supply. The gas supply can

be piped from the left or right side of the boiler.

If for any reason the boiler is not for the type of gas

available at the installation site, call the nearest Smith

Cast Iron Boiler distributor to resolve the problem.

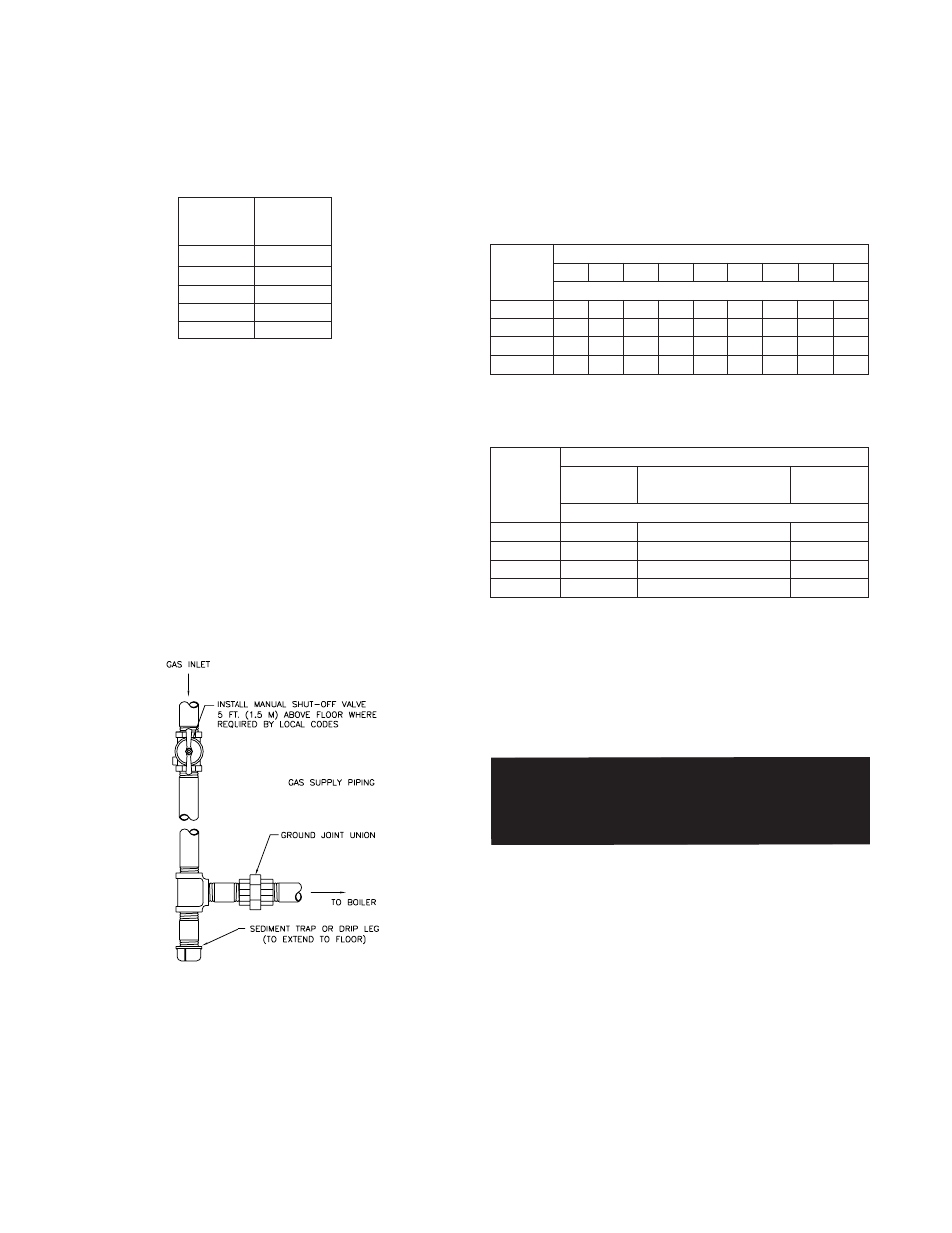

Figure 18 depicts the proper way to connect the boiler

to the gas supply piping. The manual shut-off valve

MUST be installed in the supply piping. It should be

approximately 5 feet above the floor. Provide a sediment

trap/drip leg at the bottom of the vertical section of the

gas supply pipe. A ground joint union should be installed

between the boiler gas controls and the supply piping.

Each of these items is needed to ensure long life and

ease of servicing. Always use a pipe sealant that is

suitable for use with LP gas.

Figure 18 - Gas Supply Piping

CAUTION: Always use a wrench on the gas valve

body when making gas connections to it. Never

over-tighten the piping entering the gas valve body

or the gas valve will be damaged!

Table 8 should be used to ensure that the gas supply

piping is sized properly. If more than one appliance is

supplied by the same supply pipe, the piping must be

sized based on the maximum possible demand. Do not

neglect the pressure drop due to pipe fittings. Table 9

should be used in conjunction with Table 8 to ensure

that the gas supply piping is sized properly.

Safe lighting and other performance criteria were met

with the gas manifold and control assembly provided on

the boiler when the boiler underwent tests specified in

ANSI Z21.13. All gas connections MUST be leak tested

before putting the boiler into operation.

Table 8 - Gas Pipe Capacity

Table 9 - Equivalent Pipe Length Chart

Whenever the gas supply piping is pressure tested the

boiler gas controls must be protected. If the test pres-

sure is equal to, or less than 1/2 psig (3.5 kPa) isolate

the boiler by closing it's manual shut off valve, see

Figure 18. If the test pressure is greater than 1/2 psig

(3.5 kPa), disconnect the boiler and it's individual shut-

off valve from the gas supply piping.

WARNING: Never use an open flame to test for

gas leaks. Always use an approved leak

detection method. Failure to comply with this

WARNING could result in an explosion!

ELECTRICAL WIRING

CAUTION: Label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper and dangerous operation!

ATTENTION: Au moment de l'entretien des

commandes, étiquetez tous les fils avant de les

débrancher. Des erreurs de câblage peuvent

entraîner un fonctionnement inadéquat et

dangereux. S'assurer que l'appareil fonctionne

adéquatement une fois l'entretirn terminé.

The electrical connections to this boiler/water heater

must be made in accordance with all applicable local

codes and the latest revision of the National Electrical

Code, ANSI /NFPA-70. Installation should also conform

with CSA C22.1 Canadian Electrical Code Part I if

GS110

Section

Size

3

4

5

6

7

Connection

Tapping

1/2"

1/2"

1/2"

3/4"

3/4"

Pipe length in feet

10

20

30

40

50

60

80

100

150

Gas pipe Capacity (ft

3

/hr)

278 190 152

130

115

105

90

79

64

520 350 285

245

215

195

170

150

120

1050 730 590

500

440

400

350

305

250

1600 1100 890

760

670

610

530

460

380

Nominal

Iron Pipe

Size, (in)

3

/

4

″

1

″

1

1

/

4

″

1

1

/

2

″

Type of pipe fitting

90

° Elbow

Tee

Gas Valve

Gas Cock

(branch flow)

(full port)

Equivalent length of pipe fitting in feet

2.6

5.2

0.6

1.5

3.5

6.9

0.8

1.9

4.0

8.0

0.9

2.3

5.2

10.3

1.2

3.0

Nominal

Iron Pipe

Size, (in)

3

/

4

″

1

″

1

1

/

4

″

1

1

/

2

″

Note: Maximum pipe capacity in ft

3

/hr is based on a 0.60 specific

gravity gas at a pressure of 0.5 psig and a 0.3" WC pressure drop.