Installation 4, Ma jor components and what they do, Ho rizontal piping from well to pump – Simer Pumps 2806E User Manual

Page 4: Replacing an old pump

Installation 4

For parts or assistance, call Simer Customer Service at 1-800-468-7867

Ma jor Components

And What They Do

Impeller and Jet

Impeller turns with motor shaft, causing water to fly out

from its rim by centrifugal force. Impeller rotation creates

a vacuum which pulls in more water. Part of the water

is diverted back to the jet where it passes through the

nozzle and venturi. This creates more vacuum to draw in

more water.

In shallow wells (less than 25 feet deep), the vacuum

created at the pump is enough to pull water to the

pump. There fore, for shallow well use the jet is built into

the pump.

Pre-Charged Tank

The tank serves two functions. It provides a reservoir

of water under pressure and maintains a cushion of

air pressure to prevent pipe hammering and possible

damage to plumbing components. When water is drawn

off through the house fixtures, the pressure in the tank is

lowered and the pump starts.

Pressure Switch

The pressure switch provides for automatic operation.

Pump starts when pressure drops to 30 pounds and stops

when pressure reaches 50 pounds.

Check Valve or Foot Valve

Install a check valve as close to well as possible on well

point installations. A foot valve must be installed in the

well on dug or cased wells. See Figures 1 and 2. For long

horizontal pipe runs, install check valve as close to well

as possible (all types of wells).

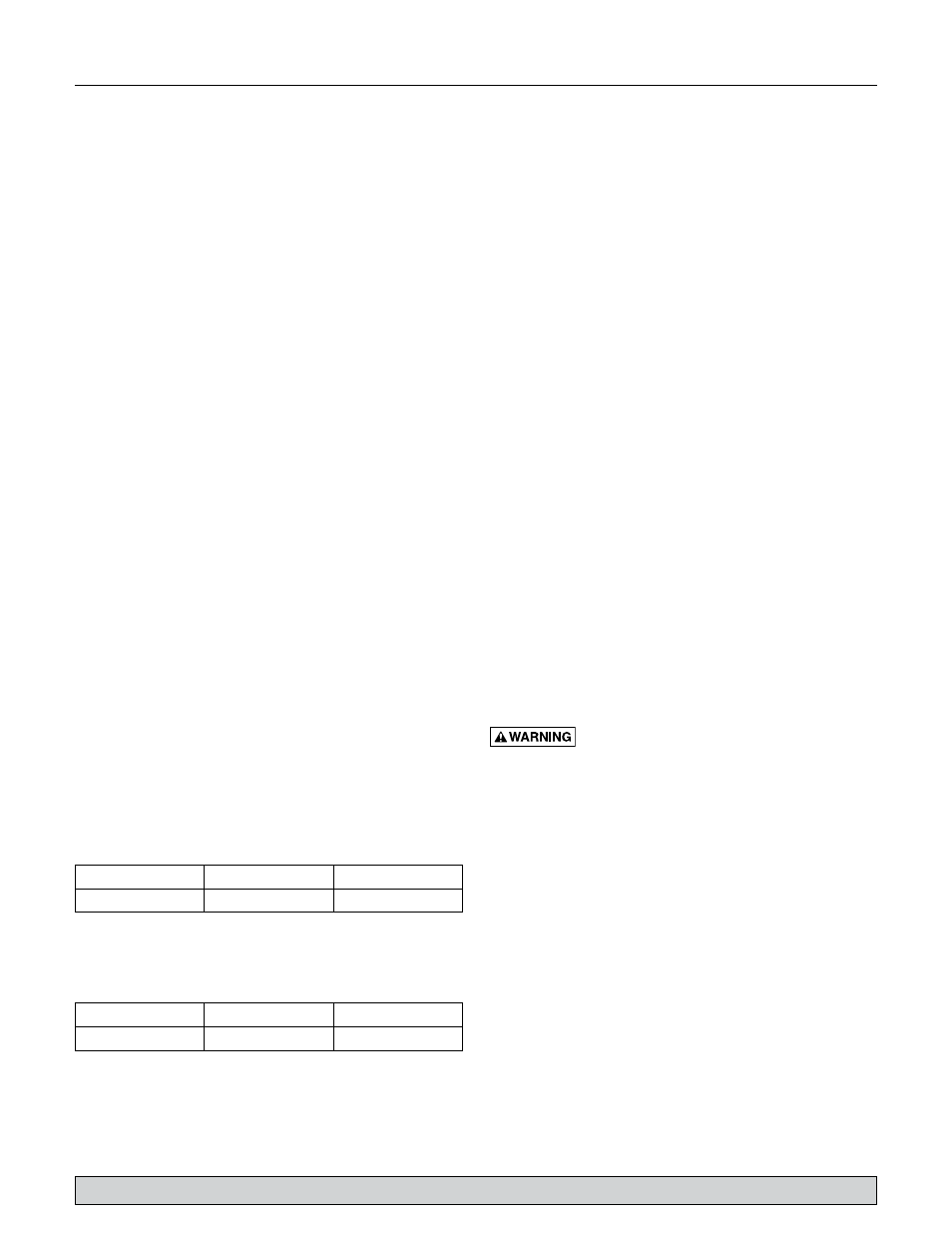

Ho rizontal Piping

from Well to Pump

When the pump is offset more than 25 feet from the

well, horizontal suction pipe size should be increased to

reduce friction losses. Never install a suction pipe that is

smaller than the suction tapping of the pump.

1-1/4”

1-1/2”

2”

Up to 25 Ft.

25 to 50 Ft.

50 to 200 Ft.

Discharge Pipe Sizes

When the pump is some distance from the house or

point of water use, the discharge pipe size should be

increased to reduce pressure losses caused by friction.

1”

1-1/4”

1-1/2”

Up to 25 Ft.

25 to 100 Ft.

100 to 600 Ft.

Tank

Tank is pre-charged with 40 pounds per square inch

(PSI) air pressure at the factory. Your tank requires an

air charge of 28 PSI for proper operation; check tank

pressure with tire gauge and adjust air charge as needed.

Tank pre-charge should be checked annually; see

Discharge Pipe and Tank Connections.

In areas where the temperature is high for long periods

of time, the tank pre-charge pressure may increase.

This may reduce the tank drawdown (amount of water

available per cycle). If this occurs, reduce the pre-charge

pressure until it is 2 PSI below the pump cut-in setting of

the pressure switch (normally 30 PSI).

It is necessary to flush all air out of the piping system and

water reservoir portion of the pre-charged tank. This is

required on new installations, pumps requiring repriming

and pumps that have been disassembled for service. Do

this as follows:

1. Open faucets furthest from tank and allow pump

to operate.

2. Air in the system will cause a sputtering flow; allow

faucets to run until you have a steady, air free stream.

3. Open and close faucets repeatedly until you are sure

all air has been removed.

4. If stream does not become steady, air may be leaking

into the system; check for leaks in the piping on the

suction side of the pump.

NOTICE: To prevent waterlogging, check tank

air charge annually. See Discharge Pipe and

Tank Connections.

Replacing An Old Pump

Hazardous voltage . Disconnect power to

pump before working on pump or motor.

1. Drain and remove the old pump. Check the old pipe

for scale, lime, rust, etc., and replace it if necessary.

2. Install the pump in the system. Make sure that all

pipe joints in the suction pipe are air-tight as well

as water tight. If the suction pipe can suck air, the

pump will not be able to pull water from the well.

3. Adjust the pump mounting height so that the

plumbing connections do not put a strain on the

pump body. Support the pipe so that the pump body

does not take the weight of piping or fittings.

You have just completed the well plumbing for your new

shallow well jet pump. Please go to Discharge Pipe and

Tank Connections.