Vibration, Doweling, Force feed lubrication – Siemens CGZ User Manual

Page 9: Installation

- 8 -

Installation

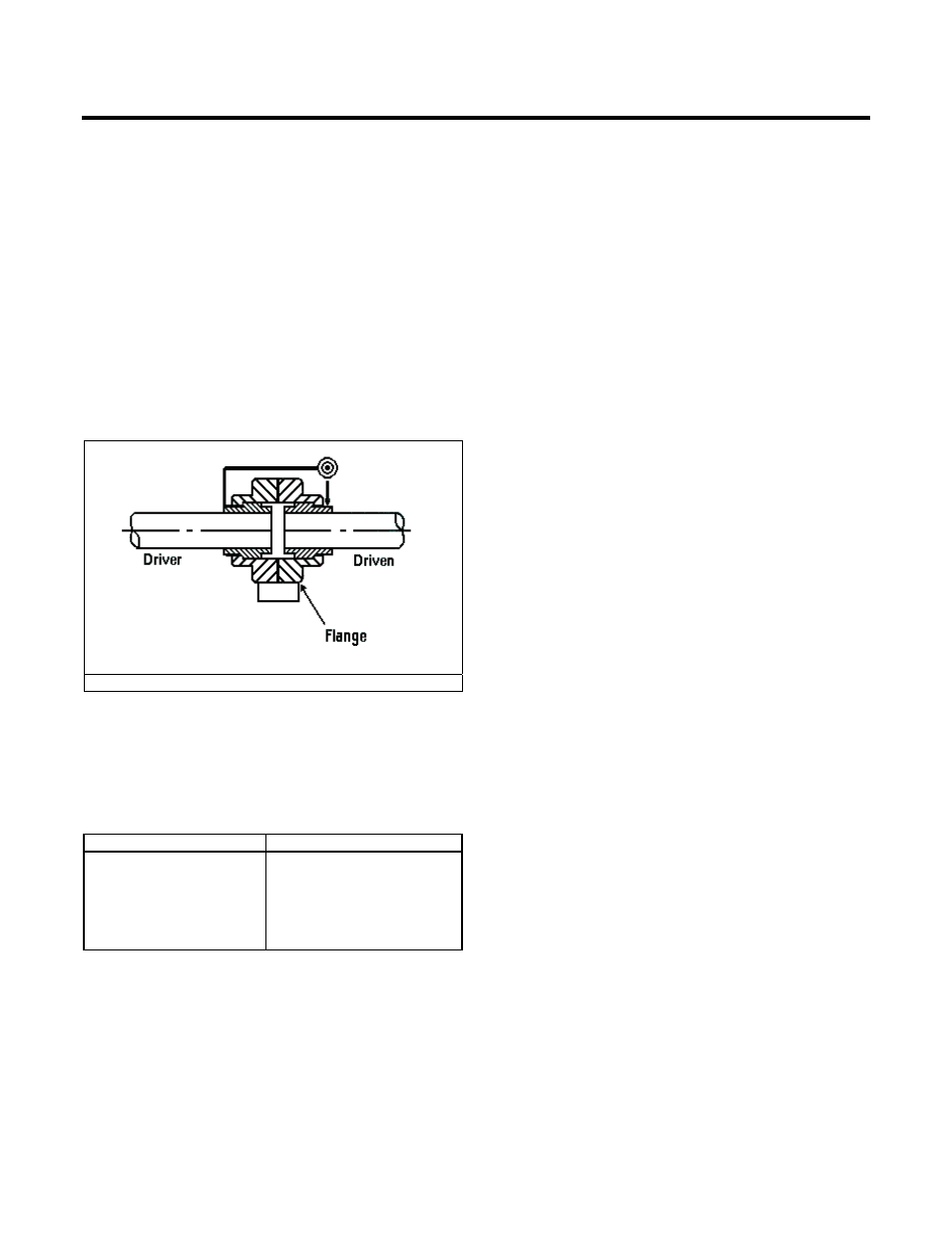

Check for vertical alignment (parallelism) of coupled

drive as follows:

1. Operate unit until normal temperature is reached

(may require several hours).

2. Shut down motor and lock out switch.

3. Mount dial indicator as in Figure 2.

4. Rotate shaft, noting readings at 0°, 90°, 180°, and

270° (both sides, top, and bottom). If within 0.002

inch total indicator reading, or other limit specified

by the factory, unit is satisfactory for operation.

5. If not within limits, add or remove shims as

required to raise or lower motor.

6. If shims are changed for high temperature

operation, repeat alignment procedure to extent

necessary to assure proper alignment. Document

readings for warranty information.

Figure 2. Check of Vertical Alignment

Vibration

The standard unfiltered housing vibration limits

measured at no load, uncoupled, and with rigid

mounting are as follows based on the requirements of

NEMA MG1-7.8.

Speed

Velocity, inches/sec peak

1200 – 3600 RPM

0.120

1000 RPM

0.105

900 RPM

0.096

750 RPM

0.079

720 RPM

0.075

600 RPM

0.063

After alignment is complete and foot mounting bolts are

tight, run motor at no load (or minimum possible).

Check for vibration. If excessive vibration exists and

the alignment is acceptable, check foot plane by

loosening one drive end-mounting bolt at a time as

detailed below. This is to be documented for warranty

information. When resiliently mounted, allowed levels

are 25% higher.

Base or foundation rigidity can also affect vibration;

check for resonance in supporting structure.

Recheck alignment after any change in shims and

document alignment readings for warranty information.

Completing Mechanical Installation

After controlling rotor end float and establishing

accurate alignment, it is recommended to drill and

ream the foundation plate and motor feet together for

dowel pins. (See Doweling).

Recheck parallel and angular alignment before bolting

the coupling together. Motor shaft should be level

within 0.03 inch after alignment.

Doweling

Doweling the motor (and driven unit) accomplishes the

following:

1. Restricts

movement.

2. Eases realignment if motor is removed from base.

3. Temporarily restrains the motor, should mounting

bolts loosen.

Inserting Dowel Pins

The following procedure is recommended:

a. Check the alignment after the unit has been in

operation approximately one week. Correct as

necessary.

b. Using pre-drilled dowel holes in motor feet as

guides, drill into the mounting base.

c. Ream holes in the feet and base to the proper

diameter for tapered dowel pins. Clean out the

chips.

d. Insert

dowel

pins.

Force Feed Lubrication

If force feed lubrication is used, flush lubrication lines

thoroughly to make sure the lines are clean before

connecting lines to bearing housings. Be sure that

bearing cavities are filled with oil to the proper level

before starting. See motor outline drawing to

determine proper oil level. Be sure that proper oil

pressure and flow are provided by the supply system.

Verify that the oil drain flow agrees with the factory

requirements. The orientation and size of oil drain

piping supplied with the motor must not be altered. Oil

drain piping should be of the same size or larger from

the motor piping to the oil sump. Piping must slope

downward. Pressure build up in the drain line between

the oil sump and the motor bearing housing can lead to

oil leakage. Document readings for warranty

information.