Maintenance – Siemens CGZ User Manual

Page 23

- 22 -

Maintenance

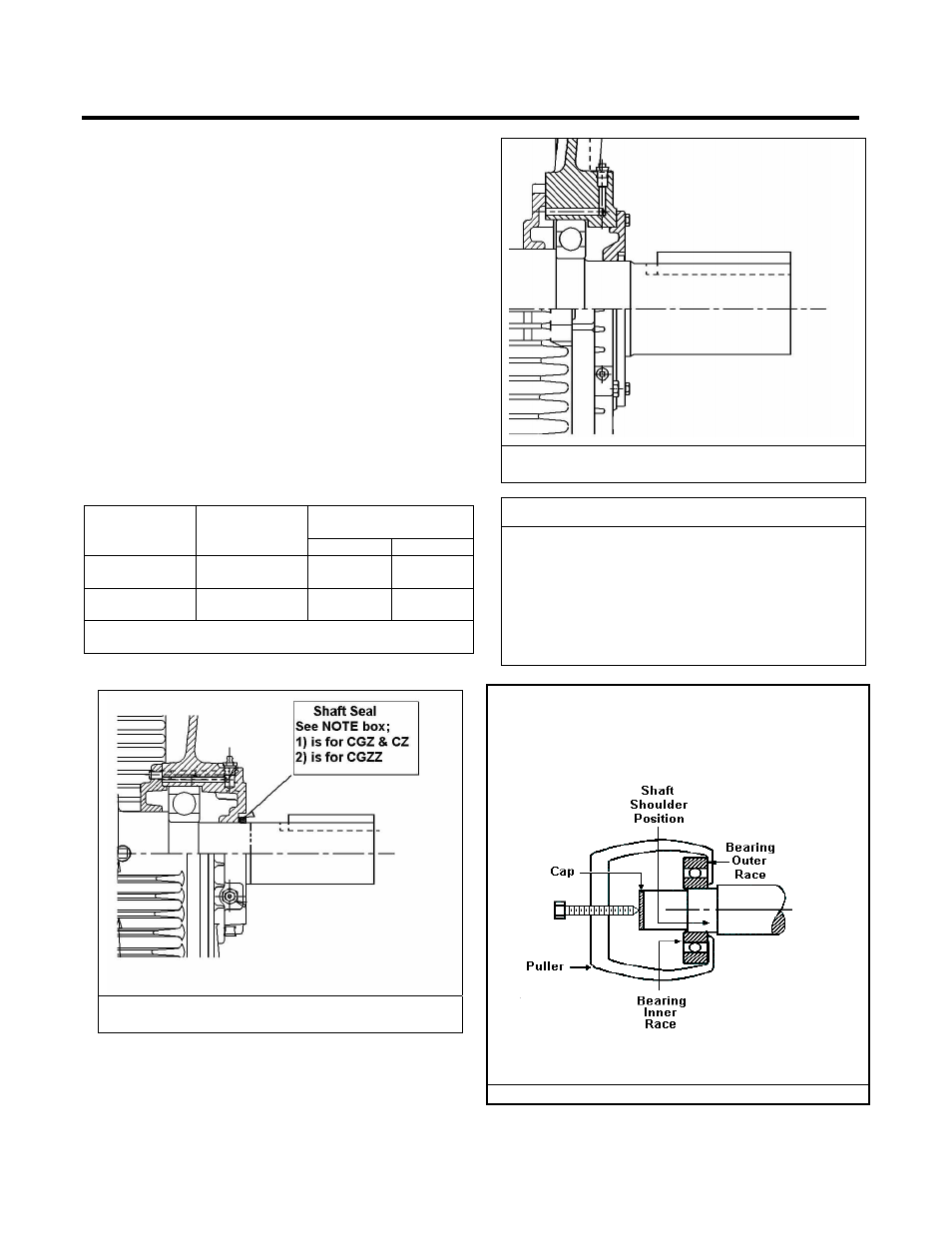

To Replace Antifriction Bearings

1. Remove bolts holding end caps to housings.

2. Remove bolts holding bearing housings to yoke.

3. Remove bearing housings.

4. Remove the bearing with a puller. See Figure 5.

5. Check shaft and housing diameter for proper size

with micrometer.

6. Heat the new bearing in an oven (200°F). While

it is hot, slide the bearing onto shaft – make

certain that the inner race makes a firm even

contact with shaft shoulder. Do not subject

bearing to impact.

7. Let bearing cool - pack bearing caps with the

proper grease.

8. Reassemble end caps and housings.

The amount of grease to be used when repacking a

bearing after cleaning or replacement is shown in the

table below:

Grease Quantity*

(End Caps)

Type

Bearing

Operating

Bearing

(Shaft)

Outer Inner

Deep Groove

Ball

Horizontal

2/3 Full

1/3 Full

Roller

Horizontal

1/3 Full

1/3 Full

*

Pack all open bearings full between balls or roller but remove

excess grease on outside of retainers.

Figure 3. Ball Bearing Construction

500, 580 and 708 Frames

Figure 4. Ball Bearing Construction

788 and 880 Frames

NOTE

1. For best results, seal should be positioned

flush with outer-most bearing housing

surface. (Some frame sizes have shaft seal

on only one end of the motor)

2.

U.L. listed motors have special requirements.

Assembly must be by U.L. certified shop or

inspected by U.L.

Consult factory for U.L. listed motors.

Protect the shaft end with a cap. If bearing is reusable,

make certain the puller applies pressure against the

bearing inner race only. If puller will not hook the bearing

inner race, fabricate a split bushing and install it between

the bearing and the puller hooks.

Figure 5. Removing Bearing with a Puller