2 replacing timing belts, 3 lubrication specifications and considerations – Sterling EX909 User Manual

Page 27

Page 27

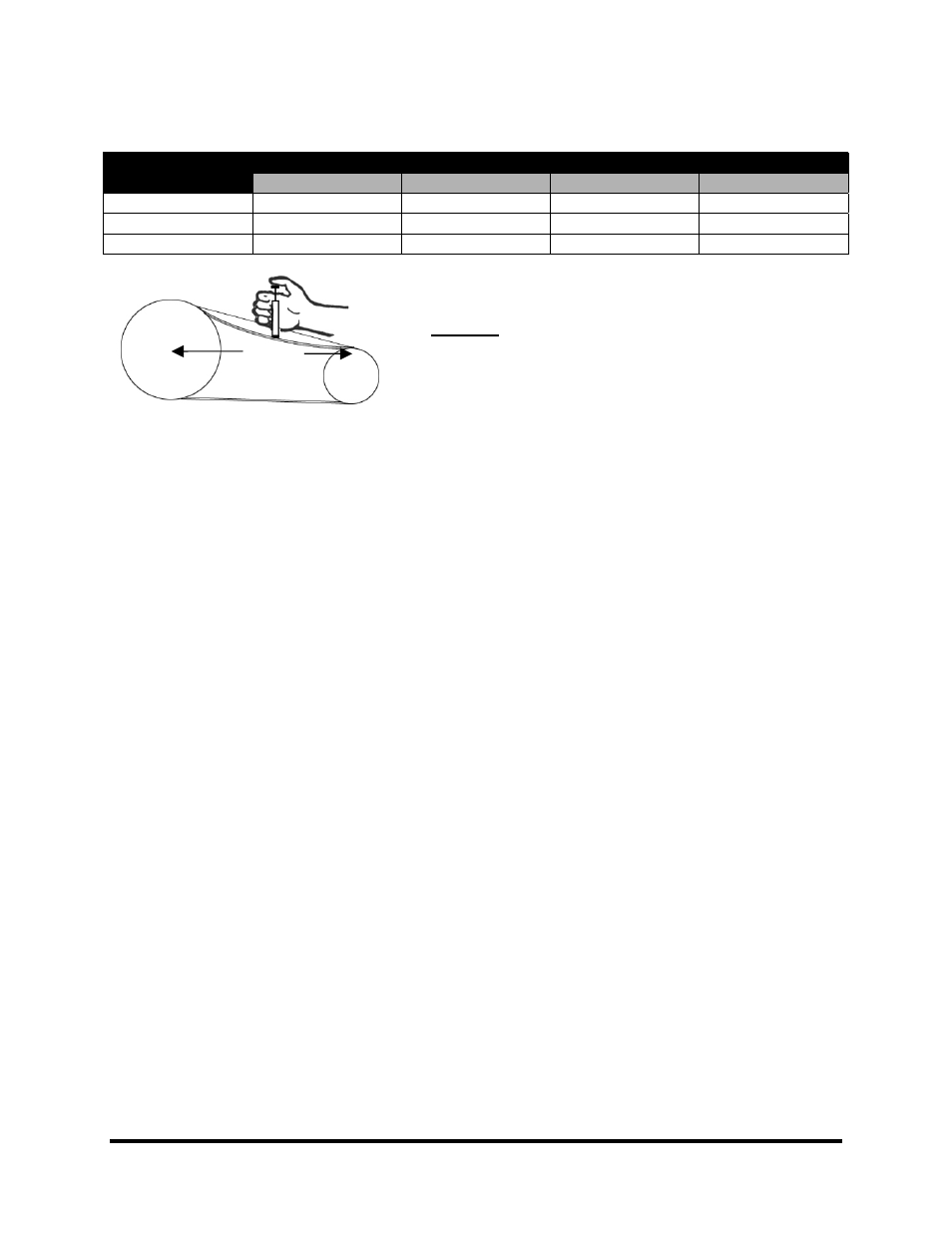

Figure 1: Belt Tensioning Chart

New Belt

Used Belt

Design HP

Min

Max

Min

Max

1

442

443

438

440

2

466

469

459

462

3

490

495

480

485

5-2

Replacing Timing Belts

1. Remove the guard cover.

2. Find and loosen the two (2) interior guard plate screws near the

gearmotor timing belt drive from inside the sprocket guard

housing.

3. Loosen the gear motor hold-down screws and move the motor

towards the granulator rotor to allow more slack in the belt.

4. Remove the old timing belt.

5. Install the new timing belt over the sprockets.

6. Move the motor back from the granulator to reduce belt sag.

7. Verify the alignment between the gear motor and rotor

sprockets; then tighten the gear motor hold-down screws.

8. Adjust the interior guard plate to re-center the opening around

the gearmotor shaft and tighten the two (2) mounting screws.

9. Replace the guard cover.

5-3

Lubrication Specifications and Considerations

All beside-the-press granulators and accessories are supplied with

bearings that are pre-lubricated at the factory.

Mounting the bearings external to the cutting chamber results in

low maintenance and trouble-free operation.

The bearings used require a high quality, lithium-based EP

(extreme pressure) type of grease, which conforms to the NGLI

Grade 2 consistency. This grease has been chosen due to its

Belt Span

Deflection = Belt Span

64