J\xiyfo – Woodstock SHOP FOX M1099 User Manual

Page 37: J

-35-

Df[\cD('00D]^J`eZ\('&'.

J

M

@:<

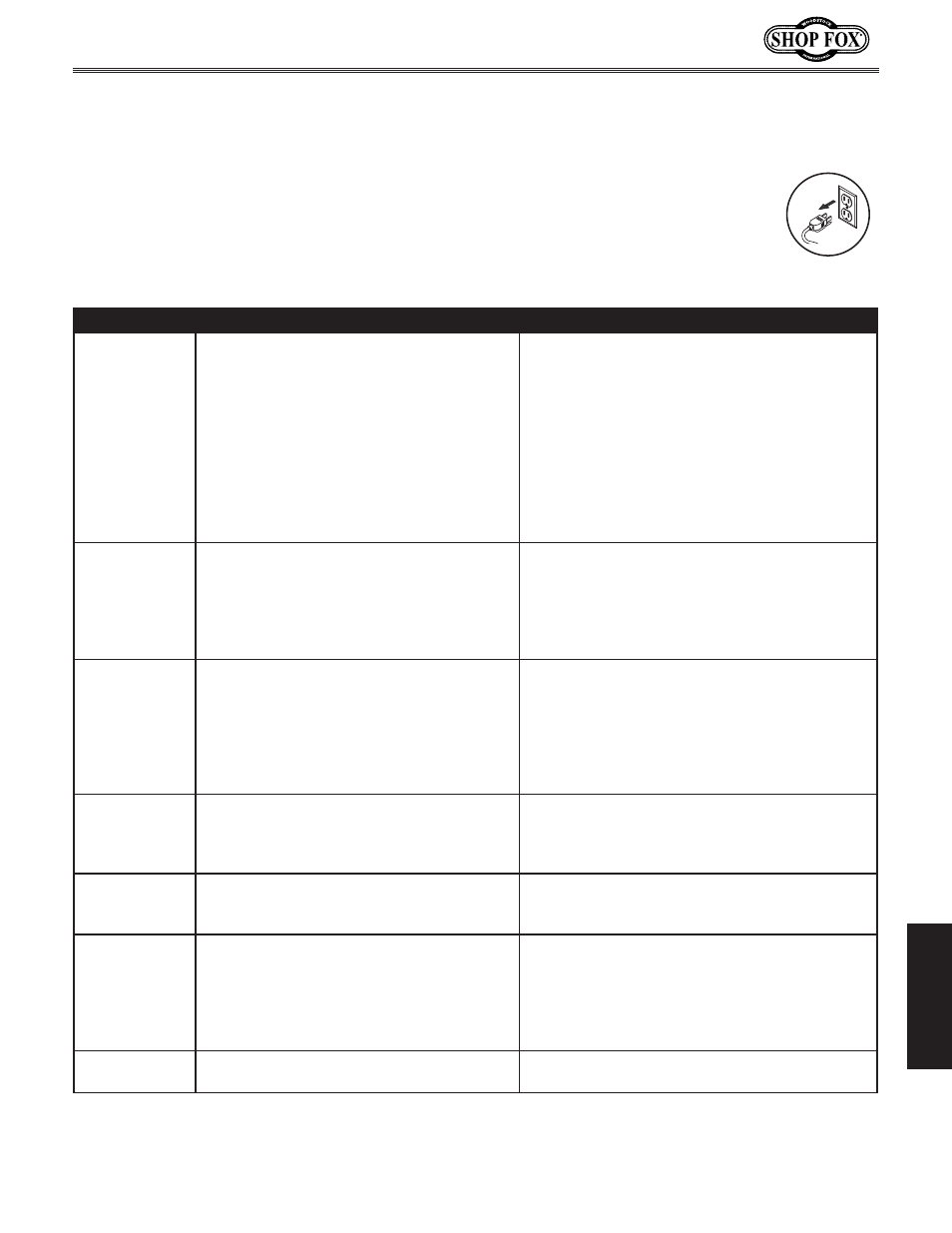

JPDGKFD

GFJJ@9C<:8LJ<

:FII<:K@M<8:K@FE

Motor will not

start.

1. Main power panel switch is

F==.

2. Emergency switch is pushed in.

3. Circuit breaker or fuse has tripped.

4. No voltage or open connection.

5. Capacitor is at fault.

6. Motor direction switch is at fault.

7. Power switch or magnetic contactor is at

fault.

8. Motor is at fault.

1. Turn the main power panel switch

FE.

2. Rotate emergency switch so it pops out.

3. Seek an electrician to troubleshoot and repair the

shop power supply.

4. Test circuit, replace wires and connections as

required.

5. Replace capacitor.

6. Replace switch.

7. Replace power switch or magnetic contactor.

8. Replace motor.

Fuses or circuit

breakers trip

open.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose connections.

3. Incorrect fuses or circuit breakers in power

supply.

1. Inspect cord or plug for damaged insulation and

shorted wires.

2. Inspect all connections on motor for loose or

shorted terminals or worn insulation.

3. Install correct fuses or circuit breakers.

Machine is

loud, belt slips

when cutting.

Overheats or

bogs down in the

cut.

1. Excessive depth of cut.

2. RPM or feed rate wrong for operation.

3. Dull cutters.

4. Belt is slipping.

5. Belt is at fault.

1. Decrease depth of cut.

2. Refer to RPM feed rate chart for appropriate

rates.

3. Sharpen or replace cutters.

4. Remove grease or oil on belt or pulleys/tighten

belt tensioner against low range belt.

5. Replace belt.

Gear change

levers will not

shift into posi-

tion.

1. Gears not aligned in headstock.

1. Rotate spindle by hand until gear falls into place.

Loud, repetitious

noise.

1. Pulley set screws or keys are missing or

loose.

2. Motor fan is hitting the cover.

1. Inspect keys and set screws. Replace or tighten if

necessary.

2. Replace fan and cover.

Motor is loud

when cutting.

Overheats or

bogs down in the

cut.

1. Excessive depth of cut or feed rate.

2. RPM or feed rate wrong for cutting

operation.

3. Cutting tool is dull.

1. Decrease depth of cut or feed rate.

2. Refer to RPM feed rate chart for appropriate

rates.

3. Sharpen or replace the cutting tool.

Levers will not

shift.

1. Gears not aligned in headstock.

1. Rotate spindle by hand until gear falls into place.

KiflYc\j_ffk`e^

Dfkfi>\XiYfo

J

This section covers the most common problems and corrections with this type of

machine.

N8IE@E>;FEFKdXb\XepX[aljkd\ekjlek`cgfn\i`j[`jZfee\Zk\[Xe[

dfm`e^gXikj_Xm\Zfd\kfXZfdgc\k\jkfg