D8@ek Page 34

Page 34

-32-

Df[\cD('00D]^J`eZ\('&'.

D

8

@EK<

E8E:

<

D8@EK

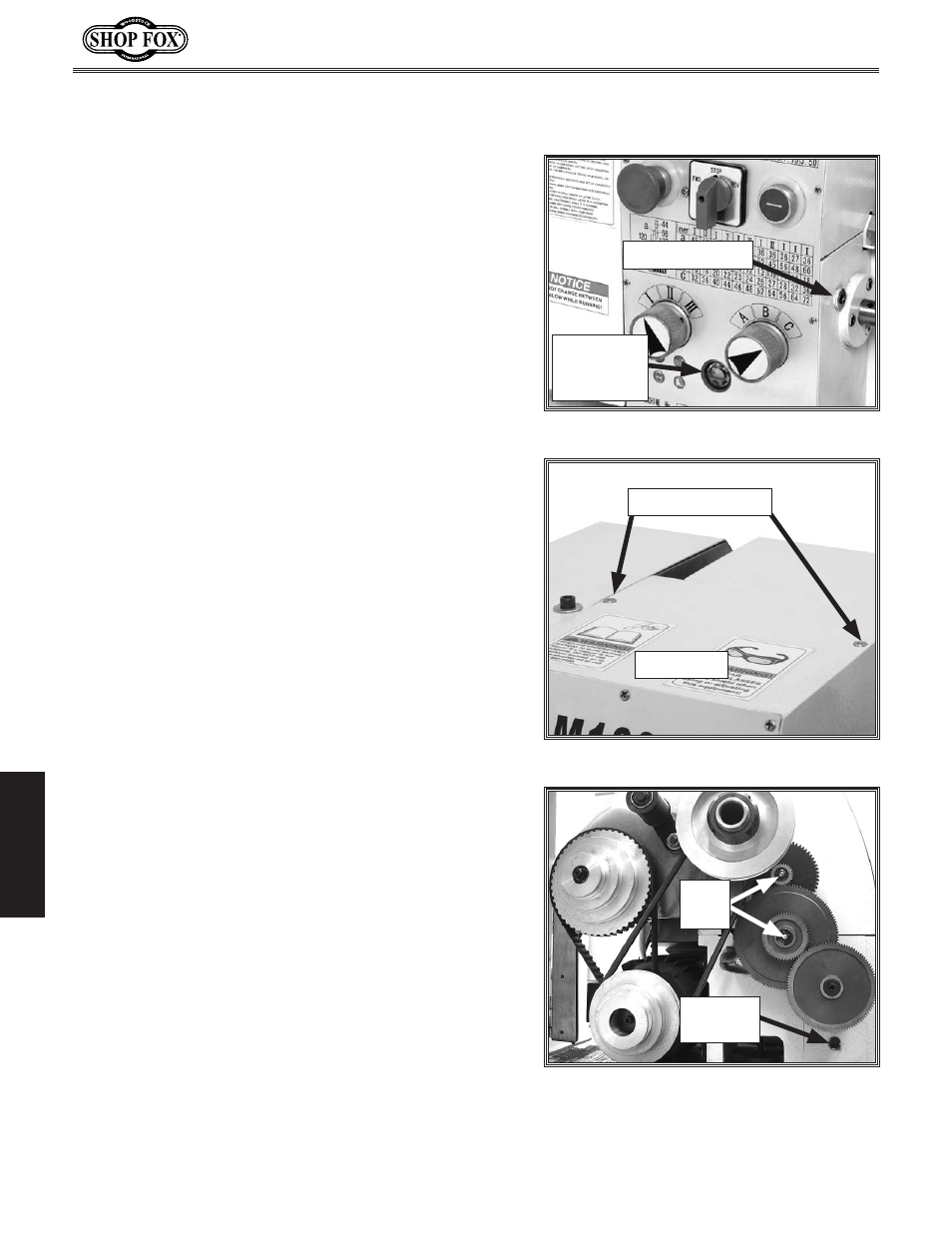

=`^li\*-% Headstock oil level sight glass.

Gearbox

Oil Level

Sight Glass

Gearbox Oil Fill

Ball

Oiler

Gearbox

Drain

=`^li\*/% Change gear ball oilers and

gearbox drain.

=`^li\*.% Spindle ball oilers in headstock.

Spindle Oil Balls

Headstock

9Xj`ZDX`ek\eXeZ\

Regular periodic maintenance of your lathe will ensure

optimum performance. Make a habit of inspecting your

machine each time you use it.

:_\Zb]fik_\]fccfn`e^Zfe[`k`fejXe[i\gX`ifi

i\gcXZ\n_\ee\Z\jjXip1

Loose mounting bolts and chuck.

Worn switch or safety features.

Worn or damaged cords or plug.

Any other condition that could hamper the safe

operation of this machine.

Make sure to unplug the lathe before lubrication and

cleaning.

Keep the gearbox oil level at

3

⁄

4

full as shown by the sight

glass (

=`^li\*-). After break-in, change the oil in the

gearbox with Mobil

®

DTE

®

Heavy-Medium or an equivalent

grade of oil, then again after three months. After that,

change the oil at the same time on an annual basis or

more frequently if extreme machine use requires it.

For daily lubrication, use a manual oil gun with a general

10W machine oil to lubricate the 11 ball oilers. Refer to

=`^li\j*.-+'for ball oiler locations. Make sure you wipe

off the fittings before you oil them.

To control surface rust on machined surfaces, wipe the

unprotected metal as required with a rust inhibiting oil.

Never blow the lathe off with compressed air, otherwise

you will force metal shavings deep into mechanisms. Use

a shop vacuum instead. Never use acetone, gasoline, or

lacquer thinner to remove stains or oil from painted sur-

faces. These chemicals will melt the paint. Use mineral

spirits or mild household degreasers.

>\e\iXcClYi`ZXk`fe