Long term storage, Maintenance (continued) – Shindaiwa EB802RT User Manual

Page 15

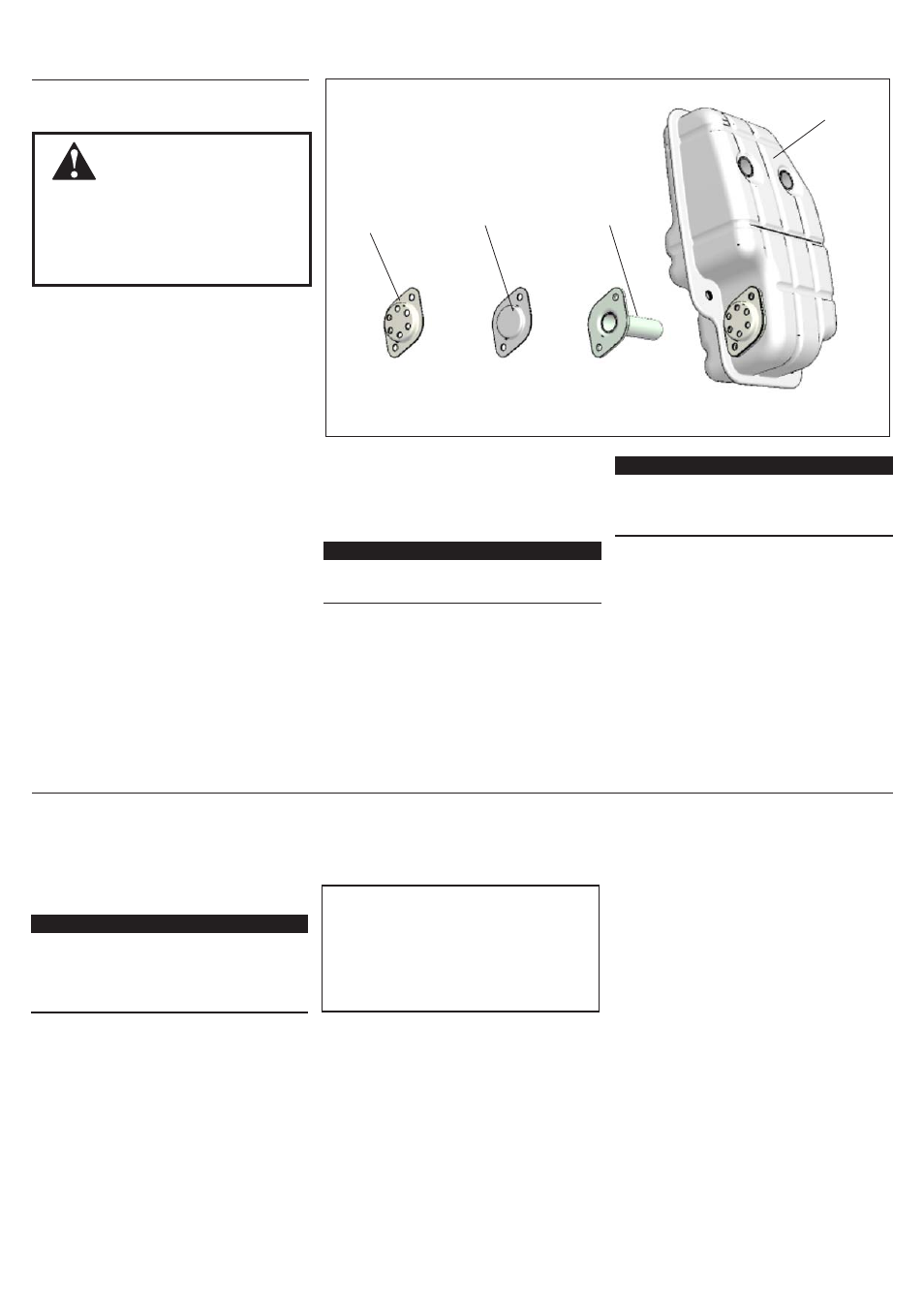

Muffler

Arrester Screen

Arrester

Screen Cover

Tail Pipe

Figure 24

15

Long Term Storage

CAUTION!

Gasoline stored in the carburetor for

extended periods can cause hard start-

ing, and could also lead to increased

service and maintenance costs.

Whenever the unit will not be used for 30

days or longer, use the following procedures

to prepare it for storage:

Clean external parts thoroughly.

Drain all the fuel from the fuel tank.

■

■

Remove the remaining fuel from the

fuel lines and carburetor:

Prime the primer bulb until no more

fuel is passing through.

■

1.

Remove the spark plug and pour about

10 cm

3

of 2-cycle mixing oil into the

cylinder through the spark plug hole.

Slowly pull the recoil starter 2 or 3

times so oil will evenly coat the interior

of the engine. Reinstall the spark plug.

Before storing the unit, repair or

replace any worn or damaged parts.

Remove the air cleaner element from the

unit and clean it as outlined in the sec-

tion, "10-Hour Maintenance".

Store the unit in a clean, dust-free area.

■

■

■

■

Start and run the engine until it stops

running.

Repeat steps 1 and 2 until the engine

will no longer start.

2.

3.

IMPORTANT!

All stored fuels should be stabilized with

a fuel stabilizer such as STA-BIL™ if

Shindaiwa One oil with fuel stabilizer is

not used.

135-Hour Maintenance

Every 135 hours of operation, remove and

clean the muffler.

WARNING!

Never operate this blower

with a damaged or missing muffler

or spark arrester! Operating with

missing or damaged exhaust com-

ponents is a fire hazard, and can

also damage your hearing!

Maintenance (Continued)

Remove the Muffler.

Use the 4mm hex wrench to remove the

five engine cover screws, and then slide

the cover from the engine.

Use the 5mm hex wrench to remove the

four muffler screws, and then remove

the muffler assembly from the engine.

Remove the Spark Arrester.

Use the screwdriver to remove the two

exhaust tube mounting screws, and then

remove the tail cap, exhaust tube, gasket,

and arrester screen. See figure 24.

Use a plastic scraper or wire brush to

remove carbon deposits from the arres-

ter screen and wipe clean exhaust base.

Inspect the screen carefully, and replace

any screen that has been perforated,

distorted, or is otherwise unserviceable.

1.

2.

3.

4.

5.

Gently tap the muffler on a wood sur-

face to dislodge any loose carbon.

Inspect the cylinder exhaust port for

carbon buildup.

IMPORTANT!

If you note excessive carbon buildup, con-

sult your servicing dealer.

Reassemble the muffler in the reverse

order of disassembly.

6.

7.

8.

IMPORTANT!

Reset the muffler screw retaining tabs

to prevent the muffler screws from

loosening.