Recold, Jw series, Pressure drop – SPX Cooling Technologies Recold JW Series User Manual

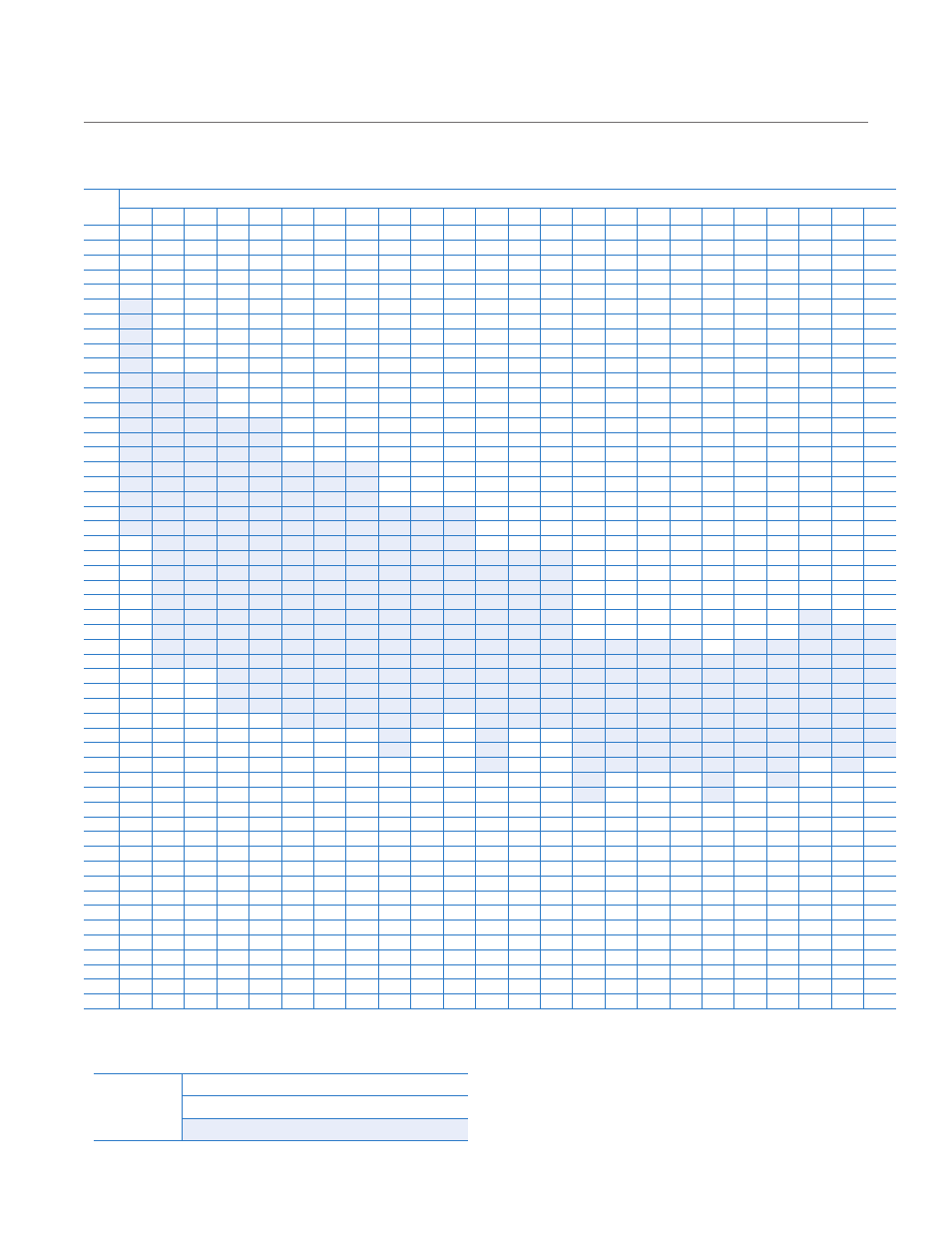

Page 11: Fluid cooler, Table no. 4: pressure drop in psi, Table no. 5: ethylene glycol flow conversion

Recold

/

JW Series

Fluid Cooler

/

Pressure Drop

11

GPM

Model JW - JWL - JWH

10A

10B

10C

15B

15C

25A

25B

25C

35A

35B

35C

50A

50B

50C

70B

70C

85B

85C

100B 100C 115B 115C 130B 130C

10

1.1

20

3.5

0.7

0.9

25

5.2

1.1

1.3

0.8

1.0

30

6.9

1.5

1.8

1.1

1.3

0.7

0.8

1.1

35

9.1

1.0

2.3

1.5

1.8

0.9

1.0

1.4

0.7

0.9

1.1

40

1.7

2.4

2.9

1.8

2.2

1.1

1.4

1.7

0.9

1.1

1.3

0.7

1.0

1.2

45

2.1

3.0

3.6

2.3

2.8

1.4

1.8

2.1

1.0

1.3

1.6

0.9

1.2

1.5

50

2.5

3.6

4.3

2.7

3.3

1.6

2.1

2.6

1.2

1.6

1.9

1.1

1.4

1.8

55

3.0

4.3

5.0

3.2

3.9

1.9

2.5

3.0

1.5

1.9

2.3

1.3

1.7

2.1

60

3.6

5.0

5.9

3.7

4.6

2.2

4.8

3.4

1.7

2.3

2.7

1.5

1.9

2.4

65

4.0

1.0

1.3

4.3

5.2

2.6

3.4

4.1

1.9

2.6

3.1

1.7

2.2

2.8

70

4.5

1.2

1.4

4.7

5.8

2.9

3.7

4.5

2.2

2.9

3.5

1.9

2.6

3.1

1.5

1.8

75

5.0

1.4

1.6

5.4

6.5

3.3

4.2

5.2

2.5

3.4

4.0

2.2

2.9

3.5

1.7

2.1

80

5.6

1.5

1.8

1.1

1.3

3.7

4.8

5.9

2.8

4.7

4.3

2.5

3.2

4.0

1.8

2.3

85

6.3

1.7

2.0

1.2

1.4

4.2

5.4

6.5

3.2

4.2

5.0

2.8

3.6

4.5

2.0

2.5

90

6.9

1.9

2.2

1.3

1.6

4.5

5.8

6.9

3.5

4.6

5.4

3.0

3.9

4.8

2.2

2.8

95

7.7

2.1

2.4

1.5

1.7

0.8

1.0

1.3

3.8

5.0

6.1

3.3

4.3

5.4

2.4

3.1

100

8.5

2.2

2.7

1.6

1.9

0.9

1.1

1.4

4.2

5.4

6.5

3.6

4.8

5.8

2.6

3.3

3.0

3.7

1.7

2.4

2.1

2.9

2.6

3.4

110

10.0

2.8

3.2

1.9

2.2

1.1

1.3

1.6

4.8

6.3

7.8

4.3

5.6

6.9

3.1

3.8

3.5

4.3

2.1

2.8

2.4

3.5

3.0

4.1

120

11.8

3.3

3.8

2.2

2.6

1.2

1.6

1.9

1.1

1.3

1.6

5.0

6.5

8.0

3.5

4.5

4.0

5.0

2.4

3.3

2.7

4.0

3.5

4.7

130

13.5

3.8

4.3

2.6

3.0

1.4

1.8

2.2

1.2

1.5

1.8

5.6

7.4

9.1

4.2

5.2

4.6

5.7

2.7

3.8

3.0

4.6

4.0

5.4

140

4.3

4.9

2.9

3.4

1.6

2.0

2.5

1.4

1.7

2.1

6.5

8.3

10.4

4.6

5.8

5.2

6.4

3.1

4.3

3.7

5.2

4.6

6.1

150

4.8

5.6

3.2

3.8

1.8

2.3

2.8

1.6

1.9

2.3

1.4

1.7

2.1

5.1

6.5

5.9

7.2

3.5

4.9

4.4

5.8

5.2

6.9

160

5.4

6.3

3.7

4.3

2.1

2.6

3.2

1.8

2.2

2.6

1.6

1.9

2.3

5.7

7.3

6.5

8.0

4.0

5.4

4.9

6.5

5.8

7.7

170

6.1

7.1

4.1

4.8

2.3

2.9

3.5

2.0

2.5

2.9

1.8

2.2

2.6

6.3

8.1

7.1

8.9

4.4

6.0

5.4

7.3

6.5

8.6

180

6.7

7.8

4.5

5.3

2.5

3.2

3.9

2.2

2.7

3.2

1.9

2.4

2.8

7.0

8.9

7.8

9.8

4.9

6.6

6.0

8.0

7.1

9.4

190

7.4

8.5

5.0

5.9

2.8

3.5

4.2

2.4

3.0

3.5

2.2

2.6

3.2

7.6

9.8

8.6

10.7

5.3

7.3

6.5

1.3

7.8

10.3

200

8.0

9.3

5.4

6.4

3.1

3.9

4.6

2.6

3.2

3.9

2.4

2.9

3.5

8.2

10.5

9.4

11.7

5.7

7.9

7.0

1.7

1.4

1.8

225

10.1 11.6

6.7

7.9

3.8

4.8

5.8

3.2

4.0

4.8

3.0

3.6

4.3

2.0

2.4

1.9

2.0

7.1

1.8

1.7

2.1

1.8

2.3

250

12.1 13.9

8.2

9.5

4.5

5.8

6.9

3.9

4.8

5.8

3.5

4.3

5.2

2.3

2.9

2.3

2.6

1.9

2.2

2.2

2.6

2.2

2.8

275

9.9

11.3

5.4

6.8

8.2

4.7

5.7

6.8

4.2

5.2

6.2

2.8

3.4

2.7

3.1

2.3

2.7

2.6

3.2

2.7

3.4

300

11.5 13.0

6.4

7.8

9.5

5.4

6.7

7.8

4.9

6.1

7.2

3.3

3.9

3.1

3.6

2.7

3.2

3.1

3.8

3.2

4.1

350

15.6 17.7

8.4

10.4 12.6

7.3

8.3

10.4

6.5

7.9

9.5

3.8

4.6

4.0

4.7

3.5

4.3

3.9

4.9

4.3

5.2

400

10.6 13.0 15.6

9.2

9.4

2.8

6.8

8.5

10.3

4.3

5.3

5.1

5.9

4.4

5.4

5.1

6.2

5.4

6.5

450

11.6

2.3

3.3

8.3

2.0

3.1

5.2

6.4

6.2

7.1

5.3

6.6

6.1

7.5

6.6

8.1

500

14.3

2.7

4.0

9.9

2.3

3.7

6.3

7.7

7.4

8.5

6.4

8.1

7.4

9.1

8.1

9.6

550

3.1

4.6

12.0

2.7

4.3

7.5

9.2

8.7

10.0

7.5

9.4

8.7

1.2

9.4

1.4

600

3.1

5.0

8.6

2.5

1.7

2.9

8.8

1.2

9.9

1.4

1.9

1.7

650

3.6

5.7

9.9

2.8

2.0

3.3

9.9

1.4

1.9

1.6

1.2

1.9

700

1.9

3.2

2.2

3.7

2.0

1.6

2.2

1.8

2.5

2.1

750

2.1

3.6

2.5

4.2

2.3

1.8

2.5

2.0

2.8

2.4

800

2.4

4.0

2.8

4.7

2.5

2.0

2.7

2.3

3.1

2.7

850

2.7

4.4

3.1

5.2

2.7

2.3

3.1

2.6

3.5

3.0

900

3.4

6.0

3.1

2.5

3.5

2.9

3.9

3.3

950

3.8

6.4

3.4

2.8

3.7

3.1

4.3

3.6

1000

4.1

7.0

3.7

3.0

4.2

3.4

4.7

4.0

1100

4.5

3.6

5.1

4.1

5.5

4.6

1200

5.2

4.3

5.8

4.8

6.6

5.4

1300

6.1

5.0

6.7

5.5

7.4

6.0

1400

6.9

5.5

7.7

6.4

8.5

7.0

1500

7.9

6.4

8.6

7.2

9.6

8.0

1600

8.8

7.0

9.5

8.0

11.1

9.0

1700

9.8

8.0

10.8

9.0

12.1 10.0

TABLE NO. 4: Pressure Drop in PSI

For feet of head, multiply by 2.31.

Factor

Ethylene Glycol % by Volume

20%

30%

40%

50%

1.04

1.05

1.05

1.06

TABLE NO. 5: Ethylene Glycol Flow conversion

Note: For ethylene glycol pressure drop calculation, the

conversion factor from Table 5 must be applied to

design flow before entering Table 4.