Sharpening or replacing chipper blade, Figure 19 – Sears Craftsman 247.77055 User Manual

Page 16

16

SHARPENING OR REPLACING CHIPPER

BLADE

Because the engine on this unit has a tapered

crankshaft, a special impeller removal tool (part

number 753-0900) is required to remove the impeller

assembly. For further assistance, contact your Sears

Service Center.

NOTE:

When tipping the unit, empty the fuel tank

and keep engine spark plug side up.

•

Disconnect and ground the spark plug wire to

retaing post.

•

Remove hose assembly and bag assembly.

•

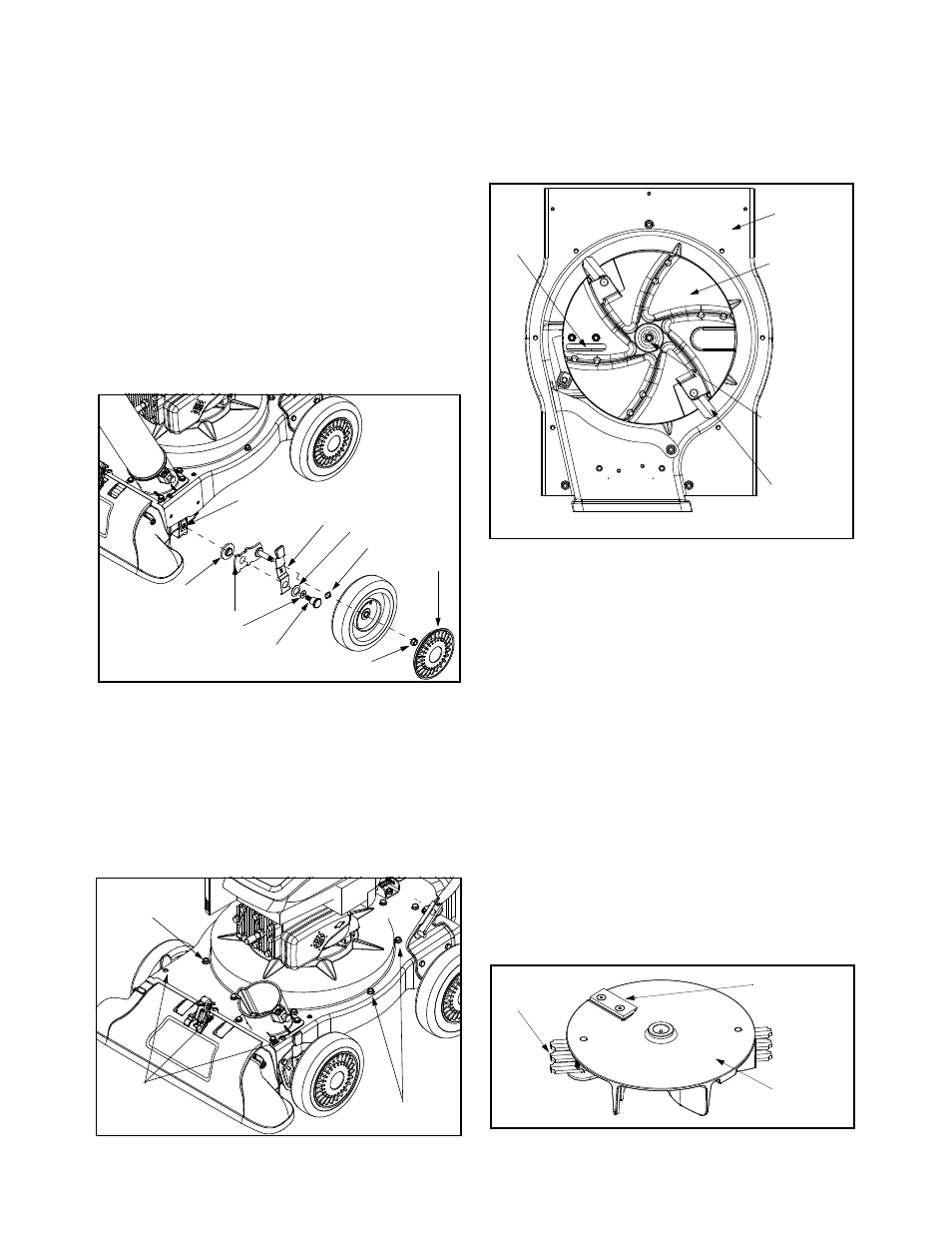

Remove the front hubcaps, flange lock nuts, front

wheels, and wave washers that attach to the pivot

arm assemblies. See Figure 19.

Figure 19

•

Remove the shoulder screws, thrust washers,

and bell washers that go through the pivot arms

to the front support brace. The front support

brace and lock nut can be removed at this time as

well.

•

Remove the three screws on the upper housing

that secure the nozzle cover and the nine screws

that secure the lower housing to the upper

housing. See Figure 20.

Figure 20

•

Remove flange lock nut that secures flail screen

to the lower housing. The flail screen does not

have to be removed. Refer to Figure 17.

•

Remove the hex bolt, lock washer, and flat

washer that secure the impeller assembly to the

crankshaft. See Figure 21.

Figure 21

•

Apply lubricant to the threads of impeller removal

tool and then thread the tool into the crankshaft.

Stop when the impeller assembly can move on

the crankshaft.

•

Remove the impeller assembly from the

crankshaft. Unthread the impeller removal tool

from the impeller assembly.

•

Remove the chipper blade using a 3/16" allen

wrench on the outside of the blade and 1/2"

wrench on the underside of impeller assembly.

•

Replace or sharpen chipper blade. The blade can

be sharpened with a file or on a grinding wheel.

•

When sharpening blade, protect hands by using

gloves and follow the original angle of grind.

•

Reassemble by performing the previous steps in

the opposite order and manner of removal.

• Tighten blade screws to 210 - 250 in-lbs.

• Tighten impeller bolt to 375 - 425 in-lbs.

NOTE:

Make certain chipper blade is reassembled

with the sharp edge facing upward. See Figure 22.

Figure 22

Hubcap

Flange Lock Nut

Wave Washer

Shoulder

Screw

Bell Washer

Pivot Arm Assembly

Thrust Washer

Front Support

Brace & Lock Nut

Bell Washer

Height Adj. Bearing

Nozzle

Screws

Lower Housing

Screws

Housing

Screws

Upper

Housing

Impeller

Assembly

Hex Bolt

Lock Washer

Flat Washer

BOTTOM VIEW

Chipper

Blade

Flail

Blade

Flail

Blade

Chipper

Blade

Impeller

Assembly