Maintenance, Return spring tension, Blade care – Woodstock 52" FOOT SHEAR M1044 User Manual

Page 18: Lubrication, Gib adjustment

-16-

M1044 52" Foot Shear

M

A

IN

TE

N

A

N

CE

MAINTENANCE

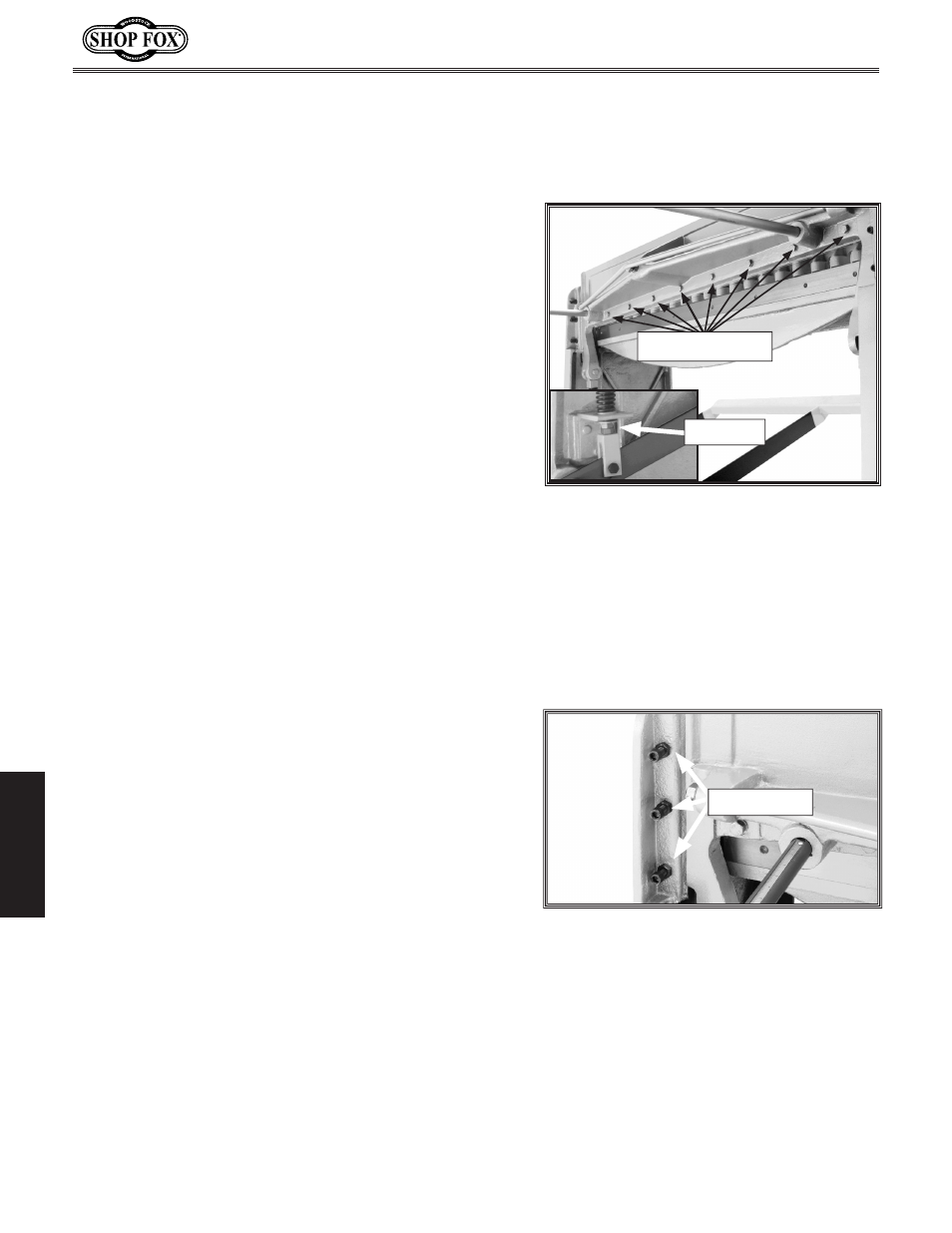

The return spring can be adjusted on the foot lever. To

increase the return rate, tighten the hex nuts against the

spring as shown in

Figure 15.

Return Spring Tension

The blades can be removed by removing the eight hex

bolts that attach the blades to the castings (see

Figure

15).

The moving blade has two cutting edges on it that are

ground with a 2° edge relief. Reverse the blade to expose

the new cutting edge as soon as one edge is dull. The

blade can be sharpened on a surface grinder by grinding

both wide sides of the blade.

The fixed blade has one cutting edge with a 2° edge

relief and a 1° face relief. It can be resharpened on a

surface grinder by grinding the wide side of the blade.

Blade Care

Figure 15. Blade bolts and return spring.

Hex Nuts

Lubricate all pivot and sliding points on this machine

daily. Lightly oil the surface of the blades and other bare

cast iron surfaces to ensure they don't develop rust.

Lubrication

When adjusting gibs, keep in mind that the goal of gib

adjustment is to remove unnecessary slide movement

without causing them to bind. Loose gibs may allow

play in the moving blade resulting in poor cuts on the

workpiece and undue wear on the slide. Over-tightening

will make lowering the foot pedal difficult.

Adjust the three gib screws on each side in small, equal

increments. Test for binding or play after each adjustment

by pushing and pulling the top of the cutter bar.

Gib Adjustment

Figure 16. Gib screw location.

Gib Screws

Blade Hex Bolts