Blade adjustment – Woodstock 52" FOOT SHEAR M1044 User Manual

Page 14

-12-

M1044 52" Foot Shear

SE

T

U

P

The blade adjustment has been made at the factory

before shipment. A few test cuts will determine if this

adjustment is satisfactory for your needs. If it is, you are

ready to start using your foot shear. However, you may

find it necessary to check the blade adjustment before

continuing. Depending on how often you change the type

and gauge of material you cut, this adjustment process

will become routine.

To perform the blade set up, do these steps:

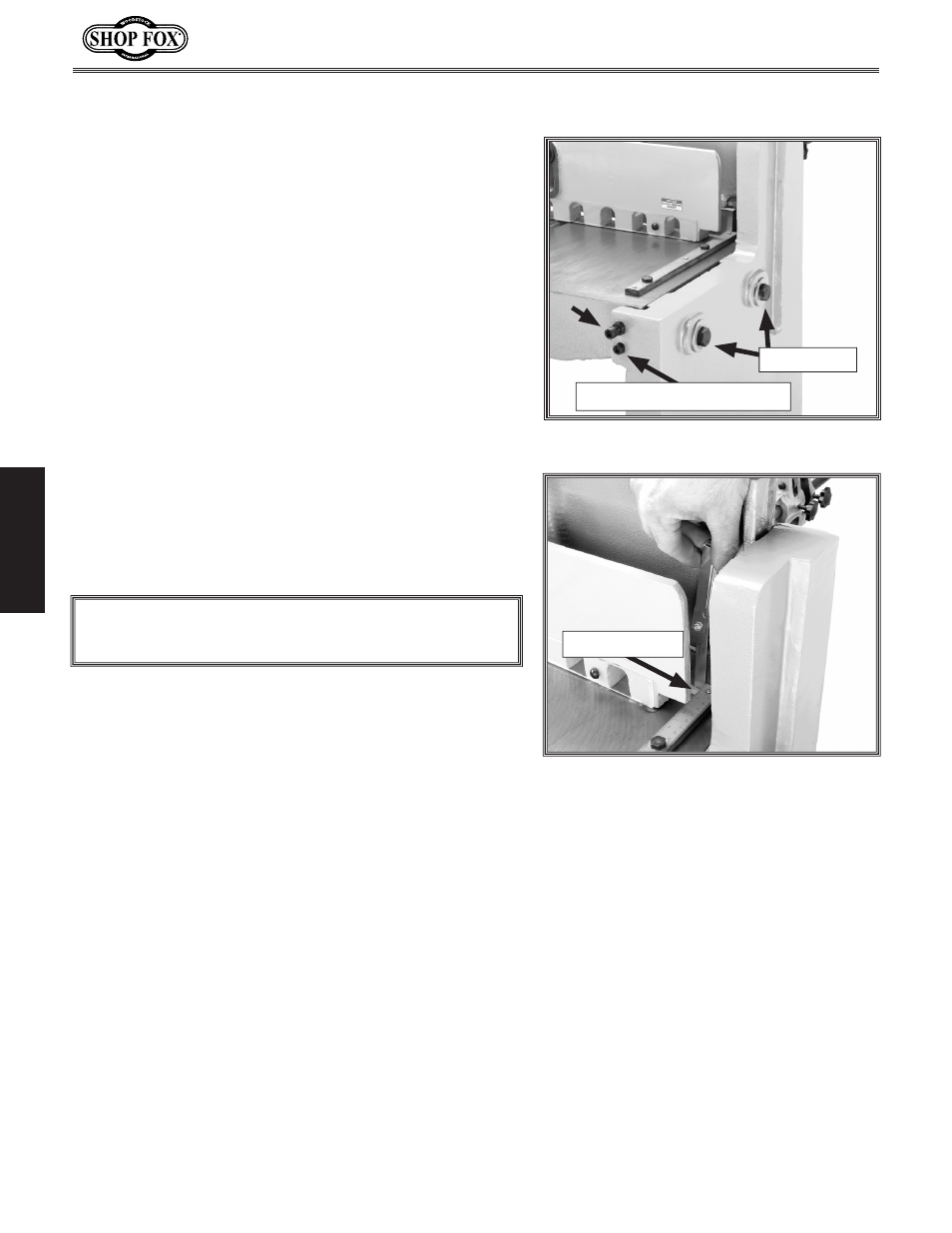

1. Loosen, but do not remove the two table bolts and

table adjustment screws on both sides of the foot

shear (see

Figure 9).

2. Using the foot pedal, lower the blade and hold it in

position. (It may help to have your assistant do this

step.)

3. Turn the table adjustment screws to move the table

and fixed blade until the fixed blade makes light

contact with the moving blade.

Blade Adjustment

7. Repeat Step 6 on the other side so

the gap is uniform across the length

of the blade.

8. Tighten the four leg bolts and double

check the gap to make sure it has not

changed. If it has repeat the process.

Figure 9. Adjustment screws.

Table Bolts

Figure 10. Measuring gap between blades.

Gap Distance

Table Adjustment Screws

4. Looking behind the pressure plate, make sure the

two blade surfaces appear to make light contact all

the way across the length.

—If they do, proceed to the next step.

—If you observe a gap between the two blade sur-

faces move to the

Adjusting Blade Bow section.

5. Using a sheet of paper, confirm that you have proper

contact by making several cuts along the length of

the blade. The shear should cut through the paper

cleanly.

6. Turn the table adjustment screws to move the fixed

blade away from the moving blade so you have a

gap of 0.002". Check this measurement with a feeler

gauge as shown in

Figure 10.

Note: The gap width will change depending on the

type and gauge of the material being sheared. This

is a trial-and-error process. Test with scrap pieces

until you achieve satisfactory results.

NOTICE: The moving blade should never overlap the

fixed blade. This will cause damage to both.