Maintenance (continued) – Shindaiwa C344 User Manual

Page 20

20

WARNING!

Sharpen only the cutting

teeth of a blade. DO NOT alter the

contour of the blade in any way.

WARNING!

Wear protective gloves

when handling or performing main-

tenance on the blade.

Round

File

When the cutting edges of the blade

become dull, they can be resharpened

with a few strokes of a file.

In order to keep the blade in balance,

all cutting edges must be sharpened

equally.

Multiple-tooth Circular Blade

Use a round file to maintain a radius of

0.04 to 1 to 1.5 mm (0.06”) at the base

of each tooth. Cutting edges must be

offset equally on each side.

Maintain a radius of 0.04 to 1 to 1.5 mm

(0.06”) at the base of each tooth. Cutting

edges must be offset equally on each side

Multiple-tooth Circular Blade

Maintenance (continued)

Blade Sharpening

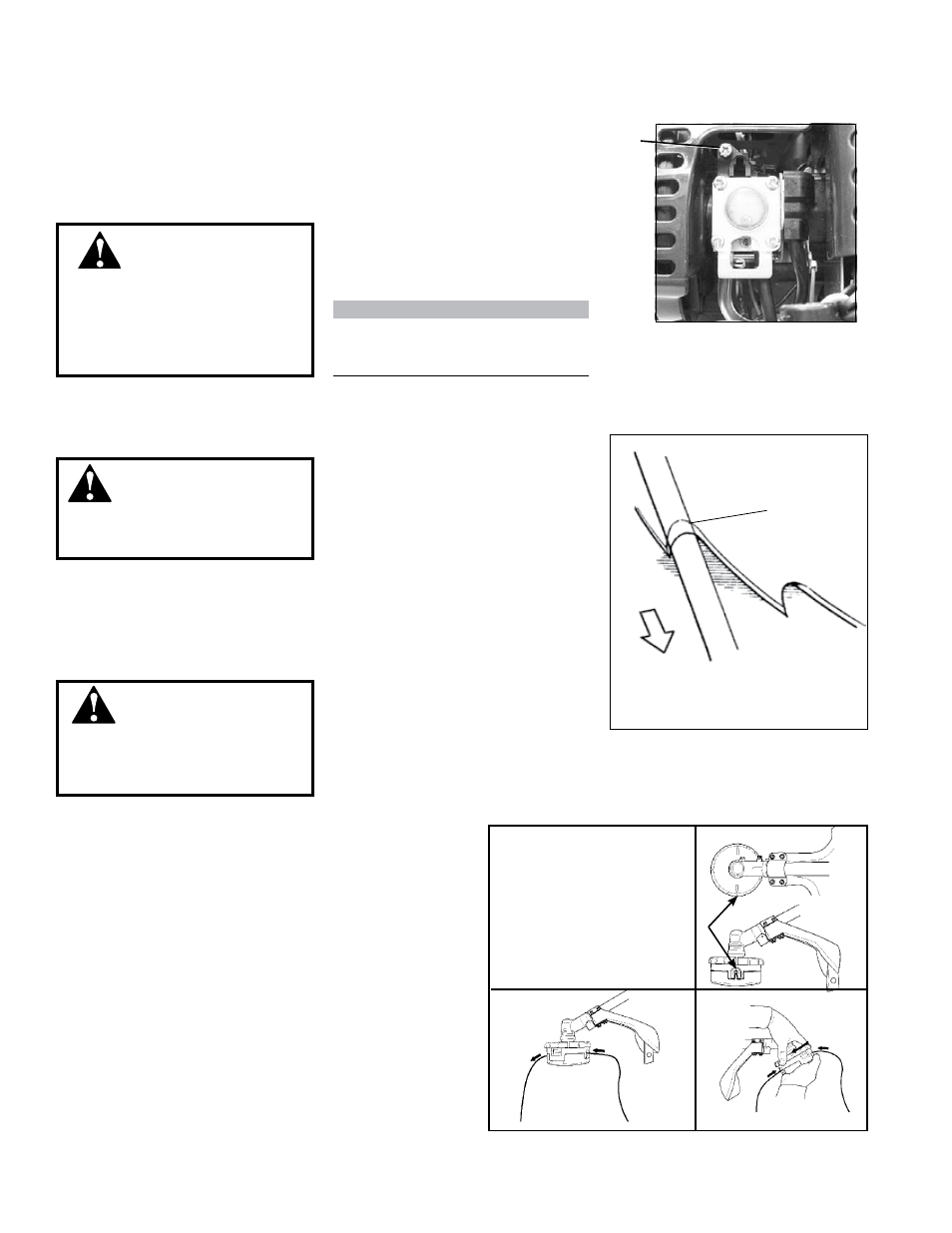

Adjusting Engine Idle

The engine must return to idle speed

whenever the throttle lever is released.

Idle speed is adjustable, and must

be set low enough to permit the

engine clutch to disengage the cutting

attachment.

WARNING!

The cutting attachment

must NEVER rotate at engine idle!

If the idle speed cannot be adjusted

by the procedure described here,

return the unit to your Shindaiwa

dealer for inspection.

Idle Speed Adjustment

Place the unit on the ground, then

1.

start the engine, and then allow it to

idle 2-3 minutes until warm.

If the attachment rotates when the

2.

engine is at idle, reduce the idle

speed by turning the idle adjustment

screw counter-clockwise.

If a tachometer is available, adjust

3.

idle. Check Specifications page for

correct idle speed

NOTE

Carburetor fuel mixture adjustments

are preset at factory and cannot be

serviced in the field.

Idle

Ajust-

ment

Screw

Loading Trimmer Line

Cut one piece of line to recommended length.

1.

Align arrows on top of knob with openings in eyelets.

2.

Insert one end of trimmer line into an eyelet, and

3.

push line equal distance through trimmer head.

Hold trimmer head while turning knob clockwise to

4.

wind line onto spool until about 5” (13 cm) of each

line remains exposed.

Trimmer head is now fully loaded and ready for

operation.

.080 (2.0 mm) dia. - 20’ (6 m)

.095 (2.4 mm) dia. - 14’ (4 m)

.105 (2.7 mm) dia. - 10’ (3 m)

1

2

3

4