Mixing fuel, Install blade, Assembly – Shindaiwa C344 User Manual

Page 10: Continued), Fuel requirements

10

WARNING!

Alternative fuels, such as E15 (15% ethanol), E-85 (85% ethanol) or any fuels not meeting Shindaiwa

requirements are NOT approved for use in Shindaiwa gasoline engines. Use of alternative fuels may cause

performance problems, loss of power, overheating, fuel vapor lock, and unintended machine operation, including,

but not limited to, improper clutch engagement. Alternative fuels may also cause premature deterioration of fuel

lines, gaskets, carburetors and other engine components.

Fuel Requirements

Gasoline - Use 89 Octane [R+M/2] (mid grade or higher) gasoline known to be good quality. Gasoline may contain

up to 10% Ethanol (grain alcohol) or 15% MTBE (methyl tertiary-butyl ether). Gasoline containing methanol (wood

alcohol) is

NOT approved.

Hybrid 4

TM

Mixture Oil - Engine oil meeting ISO-L-EGD (ISO/CD 13738) and J.A.S.O.

M345/FD

standards must be

used. Shindaiwa highly recommends using Shindaiwa Red Armor

TM

engine oil in all Shindaiwa Hybrid 4

TM

engines to

protect the engine from harmful carbon build up, maintain engine performance, and increase engine life. Shindaiwa

Red Armor

TM

engine oil exceeds ISO-L-EGD and J.A.S.O.

M345/FD

performance requirements. Engine problems

due to inadequate lubrication caused by failure to use an ISO-L-EGD (ISO/CD 13738) and J.A.S.O.

M345/FD

certified

oil will void the engine warranty.

Mixing Fuel

The unit should now be completely assembled and ready for use

with a blade.

IMPORTANT!

Discard blades that are bent, warped, cracked, broken or damaged in any way.

Use a sharp blade. A dull blade is more likely to snag and thrust.

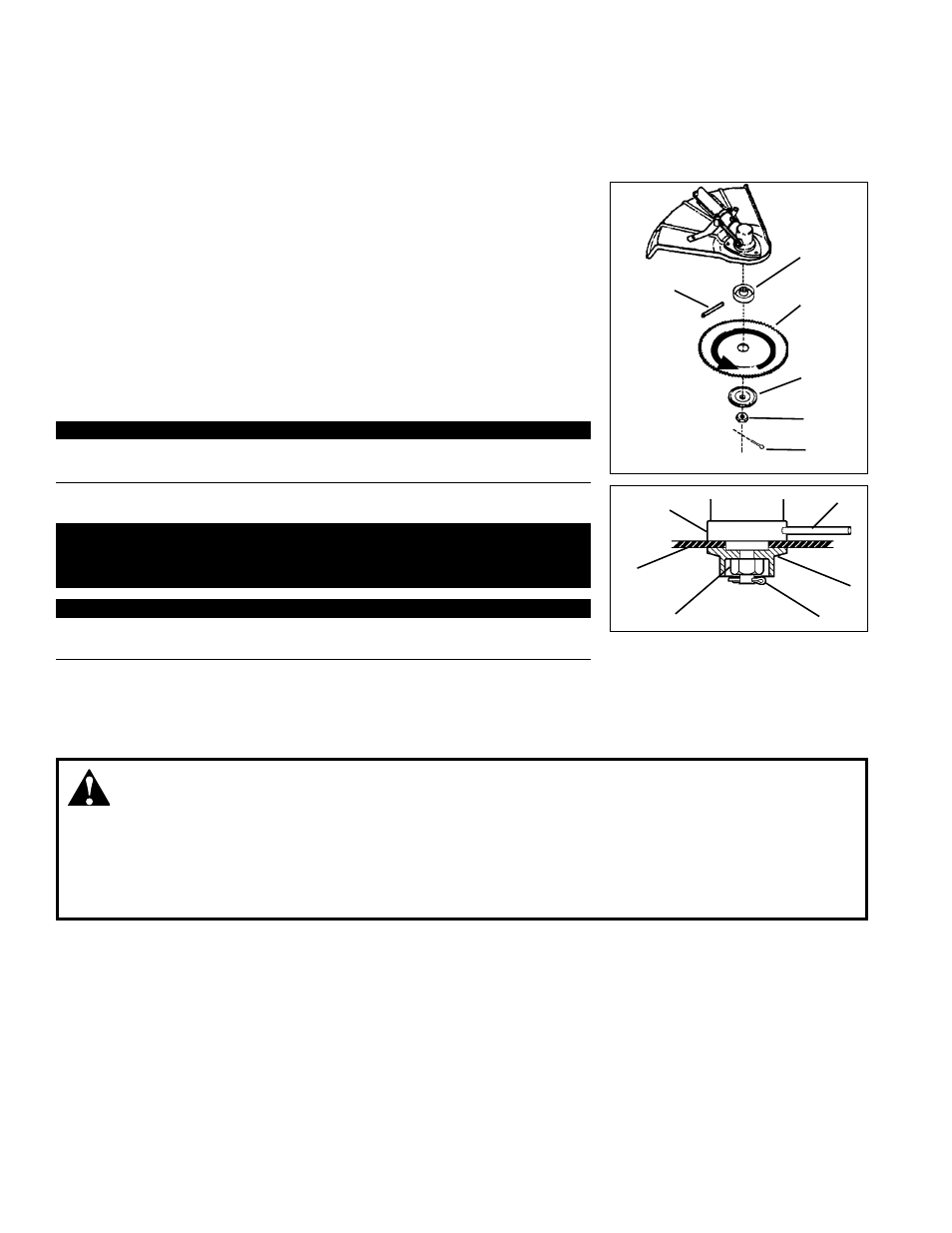

D

A

K

G

L

H

D

K

H

G

L

A

Install Blade

Tools Required: 4 mm hex key wrench (locking tool), 17 mm wrench, Pliers

Parts Required: Adapter plate w/25 mm diameter pilot, lower blade mounting

plate, 10 mm hex nut w/L.H. thread, 2 mm x 25 mm cotter pin,

blade w/25 mm arbor diameter.

1. Install adapter plate (D) on splined PTO shaft, pilot side down. Blade installa-

tion requires Upper Plate (D) with 25 mm pilot.

2. Install Blade (K) on adapter plate pilot. Blades must be installed so that rota-

tion arrow on blade matches rotation of unit: teeth toward direction of rotation

(See debris shield decal). Secure blade with Lower Plate (H), and 10 mm

L.H. nut (G). Turn nut counter-clockwise on PTO shaft to tighten.

3. Align hole in adapter plate with notch in gear housing, and insert Locking Tool

(A) to prevent splined shaft from turning. Arrow on gear housing points to

notch. Tighten 10 mm nut securely.

4. Insert Cotter Pin (L) in hole in PTO shaft, and bend pin legs around shaft

counterclockwise to retain 10 mm nut.

IMPORTANT

Never reuse a cotter pin - install a new cotter pin each time a blade is installed or

replaced.

5. Remove locking tool.

Assembly

(continued)