Sierra Monitor Corporation TR-005 User Manual

Page 2

© 2004 by Sierra Monitor Corporation

Sierra Monitor Corporation 1991 Tarob Court Milpitas, CA 95035 USA (408) 262-6611 (800) 727-4377 Fax: (408) 262-9042

Visit our Web site: www.sierramonitor.com E-Mail: [email protected]

Knowing the protocol

When a specification states that

a product has an RS-485 inter-

face, it only defines the serial elec-

trical hardware connection and

not the protocol. It is important

for the safety professional to also

know the protocol. While hun-

dreds of serial protocols exist in

the instrumentation world, the

most common serial protocol is

Modbus RTU.

Likewise, when a specification

states that a product has an

Ethernet port, it only defines the

form of the hardware interface,

commonly known as a Cat-5 cable connection.

The most common Ethernet protocol in the

industrial world is Modbus/TCP. The Modbus/

TCP de-facto standard is being rapidly chal-

lenged by EtherNet/IP in the industrial world

and standards such as BACnet/IP in the build-

ing automation world.

The gas monitoring system must be able to

hand off data and accept inputs in the protocol

format demanded by the plant-wide control

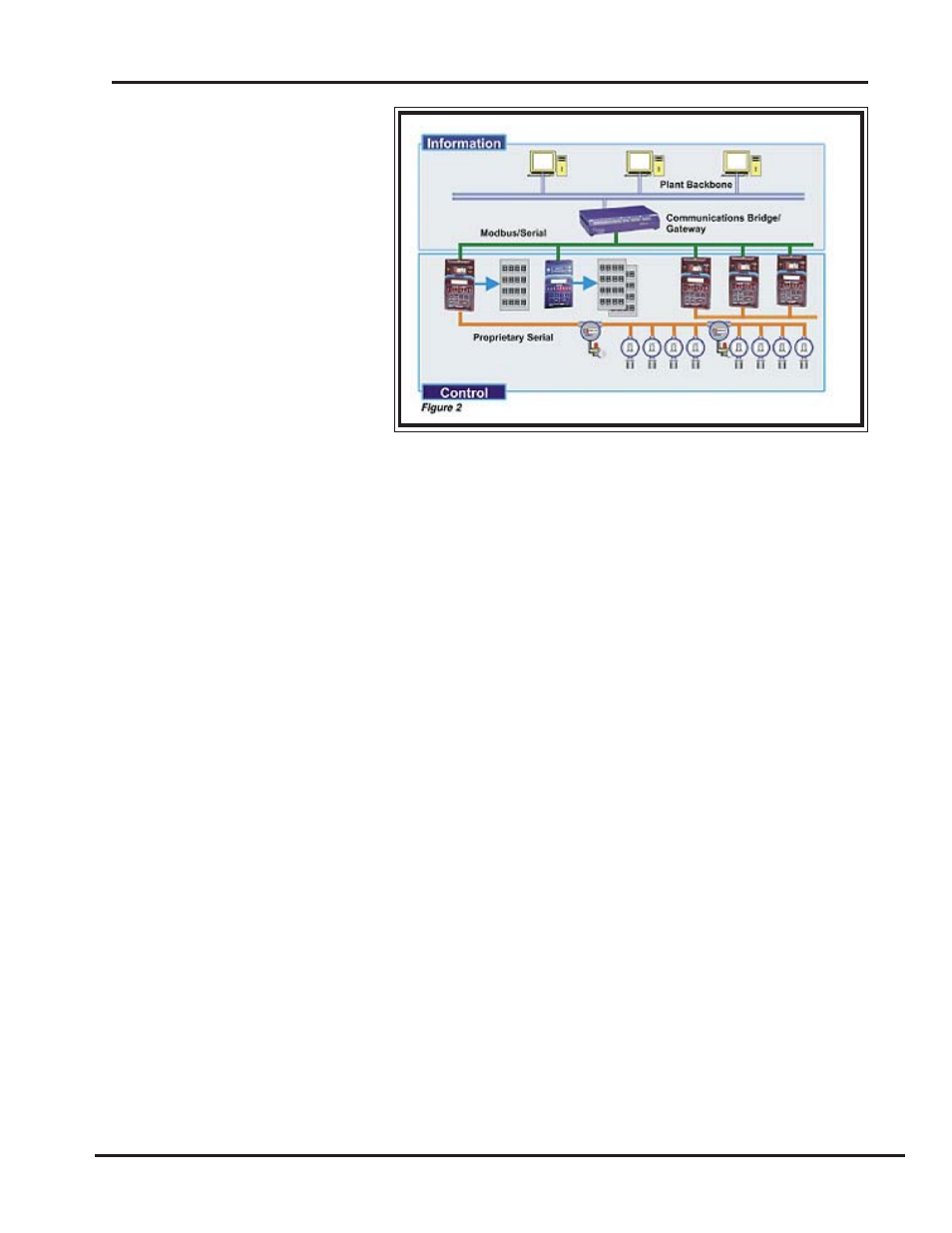

system. In Figure 2 the original single system

concept has been expanded to indicate that

multiple gas detection controllers might be

connected via a serial interface, but the pri-

mary Information layer now includes an

Ethernet backbone. Now multiple PCs can have

access to data from the gas monitoring sys-

tem. Many other devices will also reside on the

backbone, including process control or moni-

toring equipment, building management de-

vices and control room systems.

Critical to the ability to connect to the plant

backbone is the Communications Bridge or

Gateway. This device enables hardware plat-

form and protocol conversion interoperability

between dissimilar systems and the backbone.

The safety professional can breathe a sigh of

relief because his choice of monitoring system

is no longer restricted to the backbone proto-

col.

New features

Once the Ethernet interface is established, new

features of monitoring systems become avail-

able. Possibly the most useful is a Web server

function. A Web server can be installed in the

Communications Bridge/Gateway or in another

Ethernet node so authorized personnel have

desktop access to graphical representation of

the gas monitoring system status. Graphical

representation is no longer relegated to ex-

pensive, license-based, control room packages.

Other features include report by exception, re-

dundancy functions and remote datalogging,

all enabled by the Communications Bridge and

accessible via the plant backbone.

No heavy lifting here, it is all done for you.

Gordon Arnold is president of Sierra Monitor, a lead-

ing manufacturer of plant-wide gas risk monitoring

systems. He has been closely involved in the gas de-

tection industry for more than 25 years. Gordon can

be contacted at [email protected] or (408)

262-6611.