Initial installation – Sherwood Enviro EG40 DV User Manual

Page 24

support straps to the roof. Seal the nails holes heads with non-hardening mastic. Trim the excess

length of the support straps that extend out beyond the edge of the flashing.

7. Slip the flashing over the pipe section protruding through the roof. Secure the base of the flashing to

the roof with roofing nails. Use a non-hardening sealant between the uphill edge of the flashing and

the roof. Insure the roofing material overlaps the top edge of the flashing as shown in Figure 30. Verify

that you have at least the minimum clearance to combustibles at the roof line.

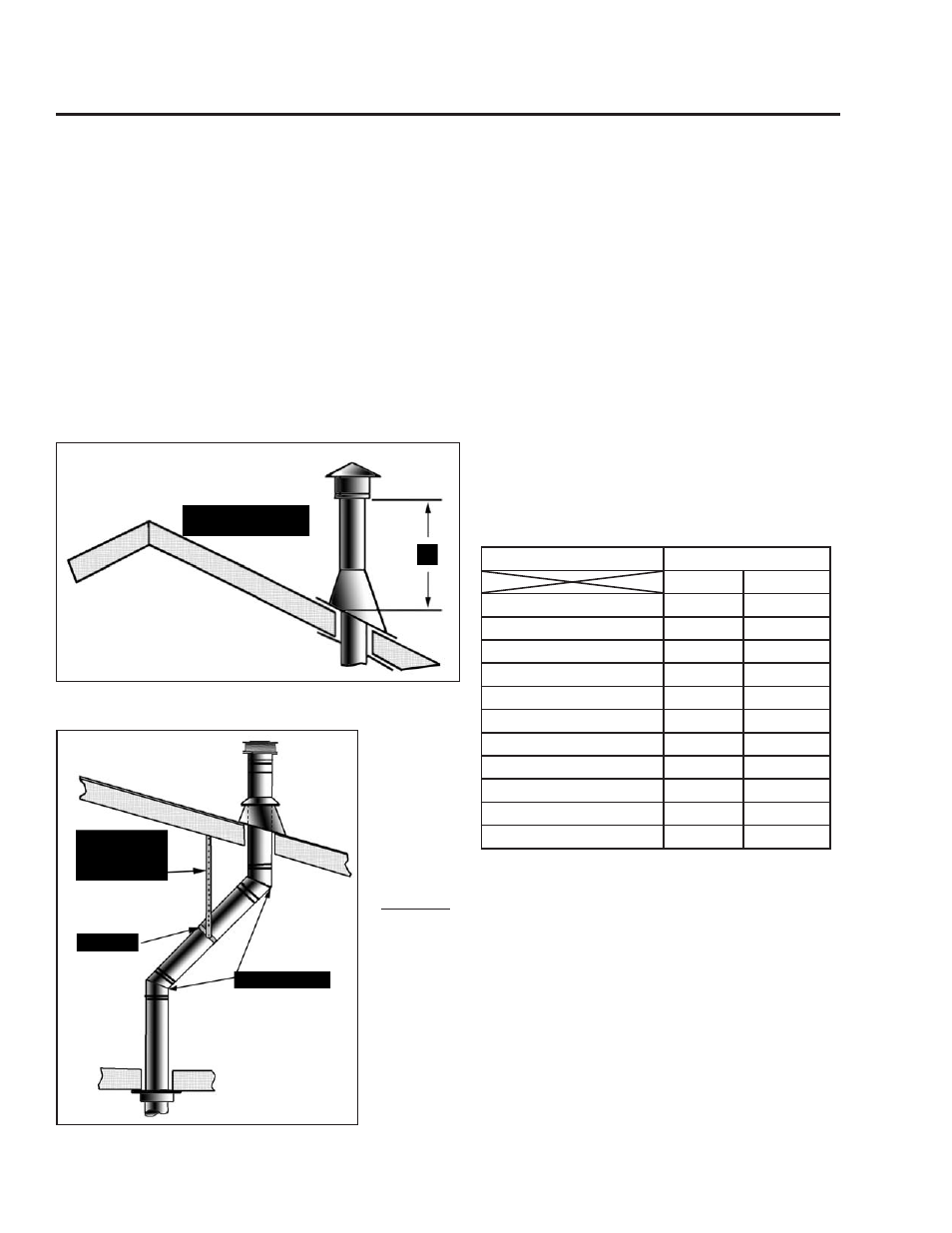

8. Continue to add pipe sections until the height of the vent cap meets the minimum code requirements.

Refer to Figure 31 and Table 5. Note that for steep roof pitches, the vent height must be increased. In

high wind conditions, nearby trees, adjoining roof lines, steep pitched roofs, and other similar factors

can result in poor draft, or down drafting. In these cases, increasing the vent height may solve the

problem.

9. Slip the storm collar over the pipe, and push it down to the top of the roof flashing as shown in Figure

Table 5: Minimum ‘H’ for Figure 31.

Roof Pitch

Minimum Height

Ft

Meters

Flat to 7/12

1

0.3

Over 7/12 to 8/12

1.5

0.46

Over 8/12 to 9/12

2

0.61

Over 9/12 to 10/12

2.5

0.76

Over 10/12 to 11/12

3.25

0.99

Over 11/12 to 12/12

4

1.22

Over 12/12 to 14/12

5

1.52

Over 14/12 to 16/12

6

1.83

Over 16/12 to 18/12

7

2.13

Over 18/12 to 20/12

7.5

2.29

Over 20/12 to 21/12

8

2.44

Figure 31: Height of Vertical Termination;

Reference Table 5.

Initial Installation

QUALIFIED INSTALLERS ONLY

Figure 32: Use of Wall Straps.

30. Use the non-hardening sealant around the

joint between the pipe and the storm collar.

10. Twist-lock the vent cap.

NOTES:

• If an offset is necessary in the attic to avoid obstructions,

it is important to support the vent pipe every 3 ft (91

cm), to avoid excessive stress on the elbows, and possible

separation. Wall straps are available for this purpose (see

Figure 32).

• When ever possible, use 45° degree elbows instead of

90° degree elbows. The 45° degree elbow offers less

restriction to the flow of flue gases and intake air.

24