Maintenance (continued) – Shindaiwa 89307 User Manual

Page 14

14

Whenever the unit will not be used for 30

days or longer, use the following proce-

dures to prepare it for storage:

Clean external parts thoroughly.

Ŷ

Drain all the fuel from the carburetor

Ŷ

and the fuel tank.

Long Term Storage

Remove remaining fuel from the fuel

Ŷ

lines and carburetor with the fuel

drained from the fuel tank. To do so:

Prime the primer bulb until no more

1.

fuel is passing through.

Start and run the engine until it stops

2.

running.

Repeat steps 1 and 2 until the engine

3.

will no longer start.

Remove the spark plug and pour

Ŷ

about 7 mL (1/4 oz.) of 2-cycle mixing

oil into the cylinder through the spark

plug hole. Slowly pull the recoil starter

2 or 3 times so oil will evenly coat the

interior of the engine. Reinstall the

spark plug.

IMPORTANT!

All stored fuels should be stabilized with a

fuel stabilizer such as STA-BIL.

CAUTION!

Gasoline stored in the carburetor for

extended periods can cause hard start-

ing, and could also lead to increased

service and maintenance costs.

Before storing the unit, repair or

Ŷ

replace any worn or damaged parts.

Remove the air cleaner element from

Ŷ

the carburetor and clean it thoroughly

with soap and water, let dry and reas-

semble the element.

Store the unit in a clean, dust-free area.

Ŷ

Maintenance (continued)

IMPORTANT!

If a new gasket is not available and/or the

old gasket is not damaged, the old gasket

may be reused. Never use cracked or

damaged gaskets!

Turn engine over several times, and

6.

returnthe to TDC-compression.

Recheck with proper feeler gauge to

make sure clearance adjustment did

not change as a result of tightening the

locknut. Readjust as necessary.

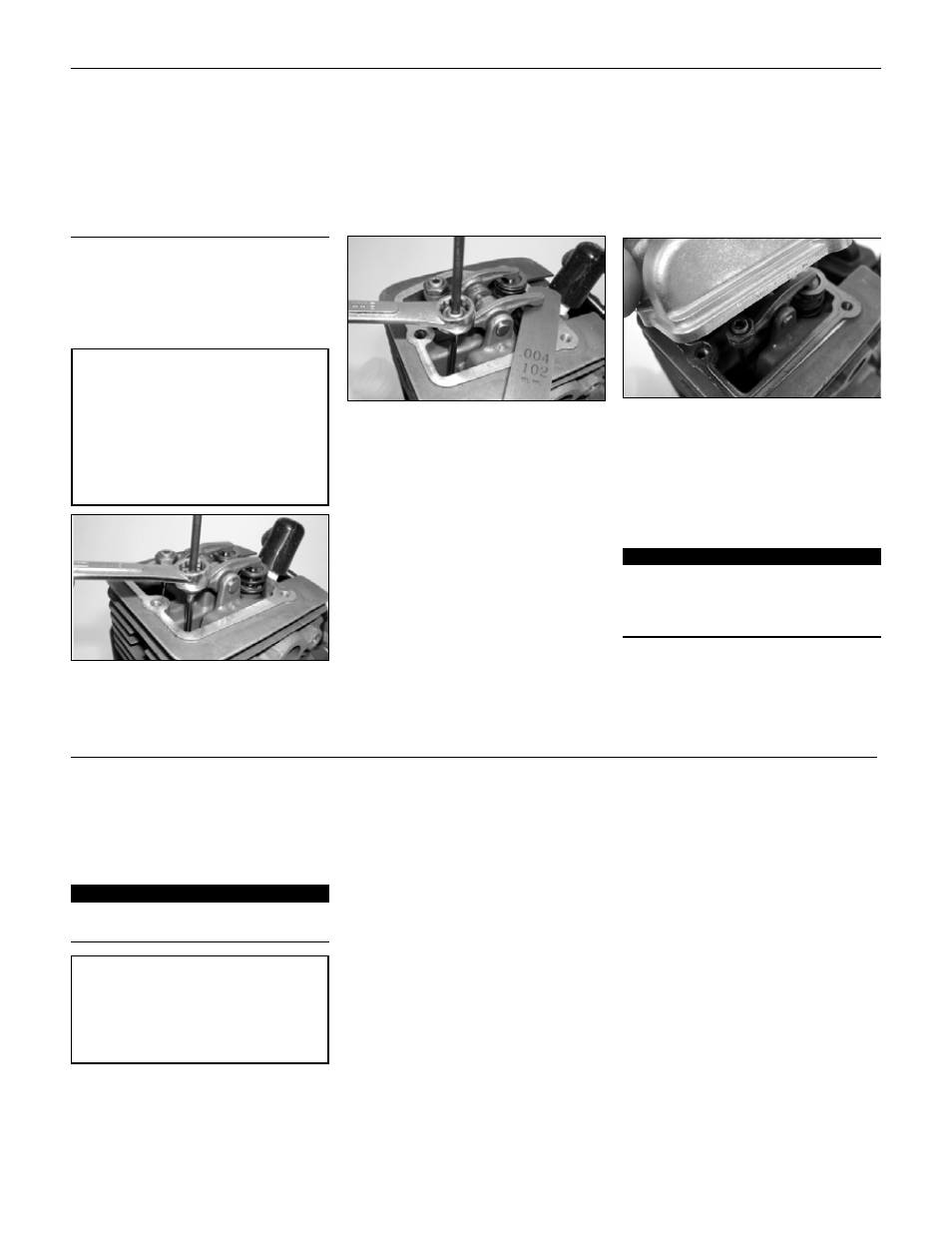

Replace rocker arm cover gasket to

7.

assure proper sealing and install cover.

Remove cylinder cover, rocker arm cover,

1.

and spark plug. Rotate the crankshaft

while observing the piston through the

spark plug opening. When the piston

is at the top of the compression stroke

(TDC), the valves can be adjusted.

Loosen adjuster locknut so that the

2.

2.5 mm Allen socket head adjustment

screw can turn freely.

Insert 0.10 mm feeler gauge between

3.

valve stem tip and rocker arm.

Turn adjustment screw (clockwise =

4.

tighter, counter-clockwise = looser)

until feeler gauge is almost snug. Back

off just enough to allow gauge to slip

out with limited resistance.

While holding the adjustment screw in

5.

place with the Allen driver, tighten the

locknut with a wrench.

CAUTION!

Performing a valve adjustment

Ŷ

incorrectly may cause hard start-

ing and/or can damage the engine.

If you are unfamiliar with this

Ŷ

engine or uncomfortable with this

procedure, consult with an autho-

rized Shindaiwa servicing dealer.

Valve Adjustment

139/150-Hour Maintenance

Maintenance after first 139-hours,

then ever y 150-hours thereafter.

Combustion chamber should be decar-

Ŷ

bonized, and the valve clearance should

be adjusted. It is highly recommended

that this is done by a Shindaiwa-trained

service technician.

Replace the spark plug annually: Use

Ŷ

only the type recommended in the

”Specifications” section or an equivalent

resistor type spark plug of the correct

heat range. Set spark plug electrode

gap to 0.6 -0.7 mm.

The valve clearance should be adjusted

Ŷ

annually or every 135 hours. It is

highly recommended that this is

done by a Shindaiwa-trained service

technician.