Hour maintenance (continued) – Shindaiwa 81719 User Manual

Page 13

1

Gearcase Protector (P/N

72958-16210)

Nut

Inspect the Gearcase Protector

The metal gearcase protector (p/n 7958-

1610) is installed to protect the gearcase

flange from damage when working close to

sidewalks or other abrasive surfaces, and

should be routinely inspected for damage

or excessive wear.

When replacing the protector, inspect to be

sure that both of the protector mounting

screws are firmly tightened and each screw

is locked in place with a nut as shown.

CAUTION!

The D-shaped shim washer must be

positioned with its flat edge toward the

shaft tube.

D-shaped Shim

Washer

Flat (toward

tube)

Shaft

Tube

Gearcase

26024

Figure 23

Figure 24

139/150-Hour Maintenance

Maintenance after first 139-hours,

then every 150-hours thereafter.

Combustion chamber should be decar-

bonized, and the valve clearance should

be adjusted. It is highly recommended

that this is done by a Shindaiwa-trained

service technician.

Replace the spark plug annually: Use

only NGK CMR5H or equivalent resis-

tor type spark plug of the correct heat

range. Set spark plug electrode gap to

0.04-0.08 inch (0.6 -0.7 mm).

NOTE:

The NGK CMR5H also meets the requirements

for electro magnetic compliance (EMC).

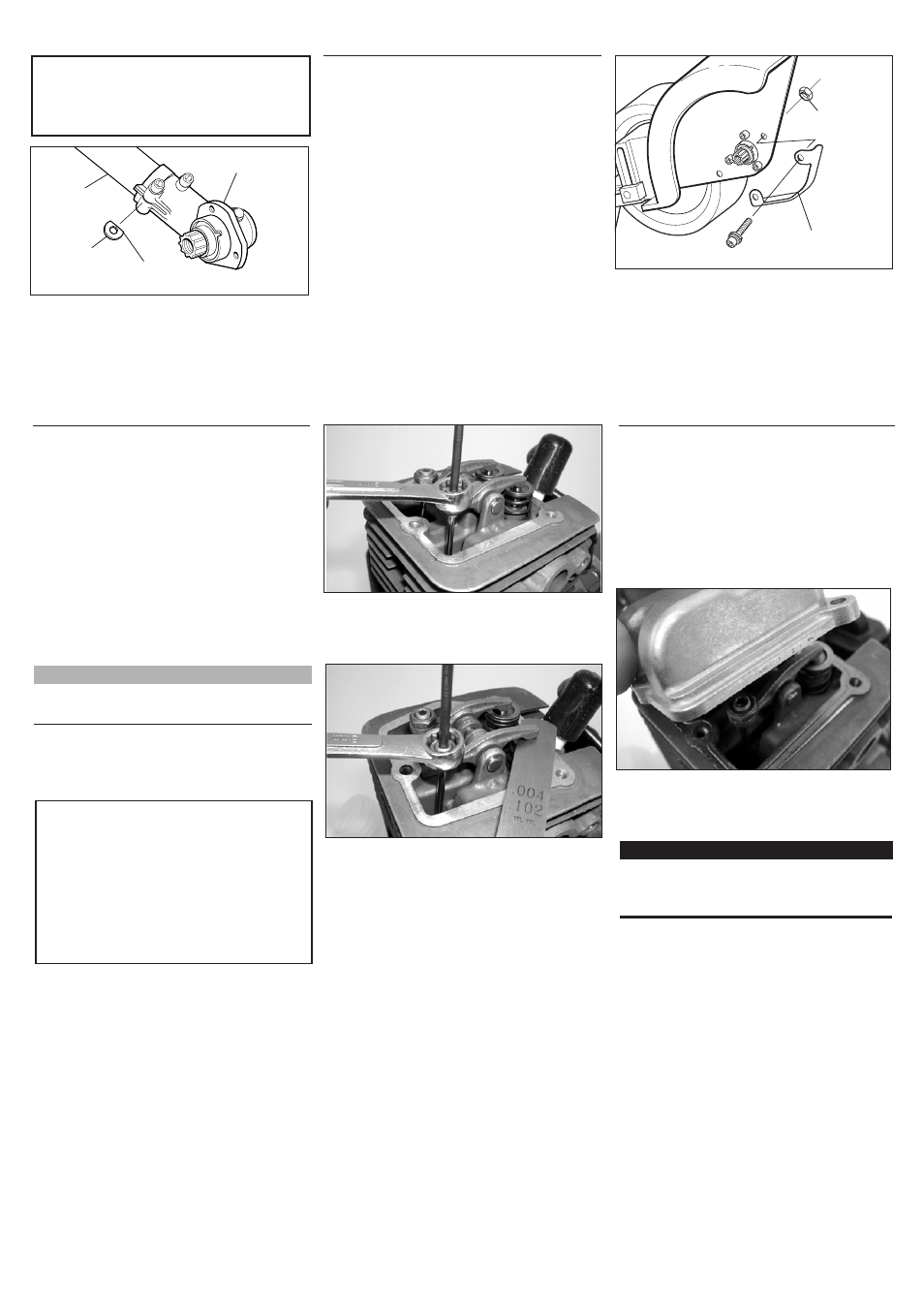

Valve Adjustment

1. Remove cylinder cover, rocker arm cover,

and set piston at TDC-compression.

. Loosen adjuster locknut so that the .5

mm Allen socket head adjustment screw

can turn freely.

. Insert feeler gauge .004” (0.10 mm) for

both intake and exhaust between valve

stem tip and rocker arm.

4. Turn adjustment screw (clockwise =

tighter, counter-clockwise = looser) until

feeler gauge is almost snug. Back off

just enough to allow gauge to slip out

with limited resistance.

7. Replace rocker arm cover gasket to as-

sure proper sealing and install cover.

IMPORTANT!

If new gasket is not available and/or old

gasket is not damaged, old gasket may be re-

used. Never use cracked or damaged gaskets!

CAUTION!

Performing a valve adjustment incor-

rectly may cause hard starting and/or

can damage the engine.

If you are unfamiliar with this engine

or uncomfortable with this procedure,

consult with an authorized Shindaiwa

servicing dealer.

5. While holding adjustment screw in place with

Allen driver, tighten locknut with wrench.

6. Turn engine over several times, and

return to TDC-compression. Recheck

with proper feeler gauge to make sure

clearance adjustment did not change as

a result of tightening locknut. Readjust

as necessary.

50-Hour Maintenance (continued)