Cutting fluid, Notice – Woodstock SHOP FOX M1054 User Manual

Page 32

-22-

M1048 10" x 18" Metal Cutting Bandsaw

O

PE

R

AT

IO

N

S

Cutting Fluid

While simple in concept and function, many issues must

be taken into account and addressed to find and use the

correct cutting fluid. Always follow all product warnings

and contact the fluid manufacturer for unanswered ques-

tions.

Use the selections below to choose the appropriate

cutting fluids:

•

For cutting low alloy, low carbon, and general-pur-

pose category metals with a bi-metal blade—use a

water soluble cutting fluid.

•

For cutting stainless steels, high carbon, and high

alloy metals, brass, copper and mild steels—use

"Neat Cutting Oil" (commonly undiluted mineral oils)

that have extreme pressure additives (EP additives).

• For cutting cast iron, cutting fluid is not recom-

mended.

Remember: Too much flow at the cutting fluid nozzle

will make a mess and can make the work area unsafe;

and not enough fluid at the cut will heat the blade, caus-

ing the blade teeth to load up and break.

Adjust the flow rate lever so the coolant will cool and

lubricate the blade, and flush the chips away so they do

not stick to the blade. If the chips build up on the blade,

eventually they will bind and skid in the next cut, break-

ing blade teeth, and damaging the bandsaw wheels.

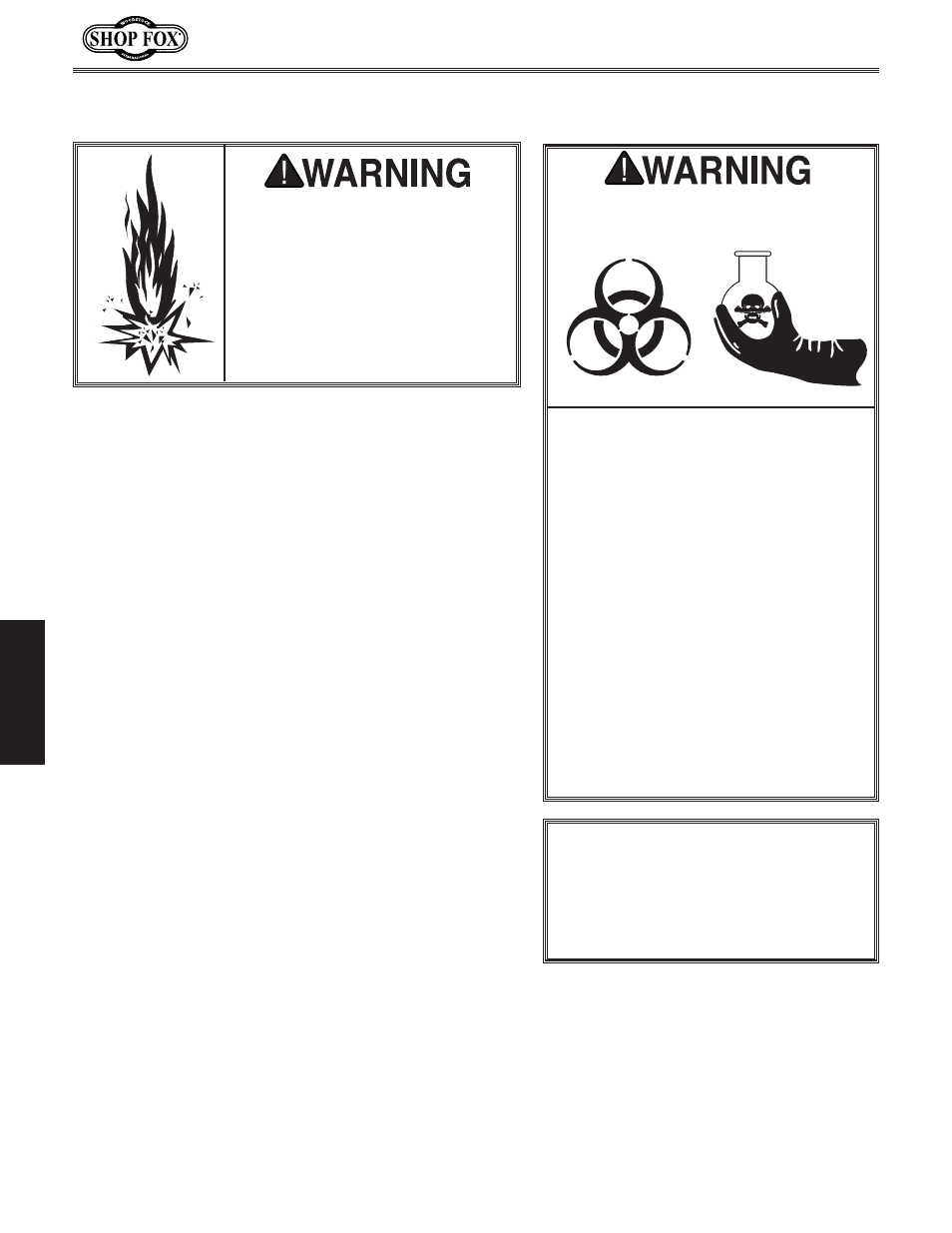

The reservoir on this machine is designed

to store cutting fluid. During storage

some fluids grow dangerous microbes,

or due to the collection of toxic metal

chips in the fluid, the fluid can become a

potent and extremely poisonous solution

to humans and animals.

USE the correct personal protection

equipment when handling cutting fluids

to prevent infections and poisoning.

USE a good bactericide and fugicide for

additional protection.

FOLLOW federal, state, and the fluid

manufacturer requirements to properly

dispose of cutting fluid when it becomes

unsafe.

BIOLOGICAL and POISON

HAZARD!

NEVER attempt to cut magnesium

when using soluble oils or emul-

sions (oil-water solutions) as a

cutting fluid! The water in the

solution will increase the risk of an

accidental magnesium-chip fire.

For cutting magnesium alloys, use

a specific cutting fluid intended

for magnesium.

NOTICE

Throughly clean and flush coolant sys-

tem when switching between coolant

types to prevent possible contamina-

tion.