Troubleshooting, Service schedule – Snapper E9266 User Manual

Page 21

21

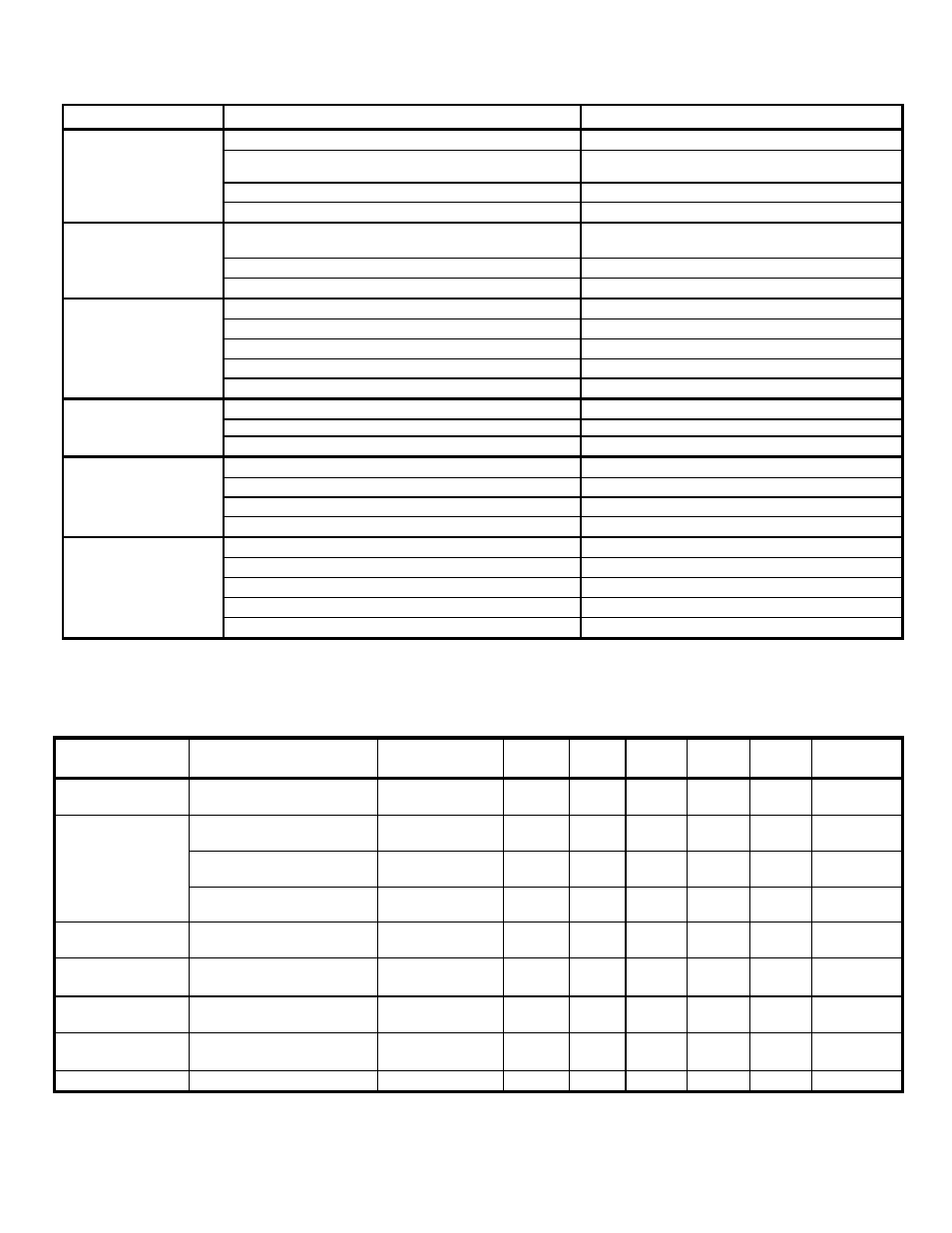

TROUBLESHOOTING

PROBLEM

PROBABLE CAUSE

CORRECTIVE ACTION

Engine Will Not Start 1. Fuel tank empty.

1. Fill fuel tank with fresh fuel/oil mix.

Using Recoil Starter

2. Engine needs choking and priming.

2. Move choke control to “CHOKE” position. Push

primer bulb three times.

3. Spark plug wire disconnected.

3. Place spark plug wire onto spark plug.

4. Fuel shut off valve closed.

4. Move fuel shut off valve to the on position.

Engine Will Not Start

Using Electric Starter

1. Power extension cord not plugged into machine or

120 Volt outlet for U.S.A. or 230 Volt for Europe.

1. Plug power extension cord into machine & into 120

Volt outlet for U.S.A. or 230 Volt for Europe.

2. Power extension cord damaged.

2. Discard damaged power extension cord.

3. Starter switch damaged or faulty.

3. Replace starter switch.

Engine Stalls or Stops 1. Water, debris or stale fuel in fuel system.

1. Drain and clean fuel system.

After Running

2. Choke control in the “CHOKE” position.

2. Move choke control to “OFF” position.

3. Fuel tank empty.

3. Fill with fuel to proper level.

4. Air intake clogged with snow or debris.

4. Unclog air intake.

5. Spark plug defective or gap set improperly.

5. Service spark plug.

Engine Loses Power 1. Engine lubrication oil level is low.

1. Add oil to the engine to full level.

2. Spark plug faulty.

2. Service spark plug.

3. Water, debris or stale fuel in fuel system.

3. Drain and clean fuel system.

Excessive Vibration

1. Damaged, out of balance or bent auger.

1. Service auger.

2. Loose engine or auger/impeller components.

2. Service and tighten loose components.

3. Bent or loose Idler pulley.

3. Tighten or replace pulley.

4. Cracked, severed or frayed belt.

4. Replace belt.

Poor Snow

1. Clogged discharge chute.

1. Stop engine and unclog discharge chute.

Discharging

2. Damaged or bent auger/impeller or components.

2. Service auger/impeller or components.

3. Cracked, severed or frayed belt.

3. Replace belt.

4. Belt tension out of adjustment.

4. Adjust belt tension.

5. Insufficient lubrication in auger bearings.

5. Lubricate all bearings as specified in manuals.

SERVICE SCHEDULE

ITEM

SERVICE PERFORMED

REF. EACH

USE

5

HRS

25

HRS

50

HRS

100

HRS

EACH

SEASON

Spark Plug

Replace Engine

Manual

X

Engine Oil

Check Oil Level

Engine Manual

X

Initial Oil Change

Engine Manual

X

Periodic Oil Change

Engine Manual

X

Air Filter

Clean or Replace

Engine Manual

Engine Cooling

System

Clean Shroud & Fins

Engine Manual

X

Drive Belts

Check For Adjustment,

Wear and Tension

Page 15-17

X

X X

Auger &

Impeller

Check For Damage &

Lubrication

Page 13

X

X

Tires

Check Air Pressure

Page 8

X